Flow through cell and manufacturing method thereof

A manufacturing method and flow cell technology, which is applied in the field of flow cells, can solve problems such as leakage, easy leakage, gap between glass substrates and spacers, etc., and achieve the effects of improving adhesion strength, high reliability, and realizing high functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Preferred embodiments of the present invention will be described below with reference to covering soil. In the examples, although an adhesive fluororesin was used as the fluororesin, a fluororesin other than the adhesive fluororesin may be used.

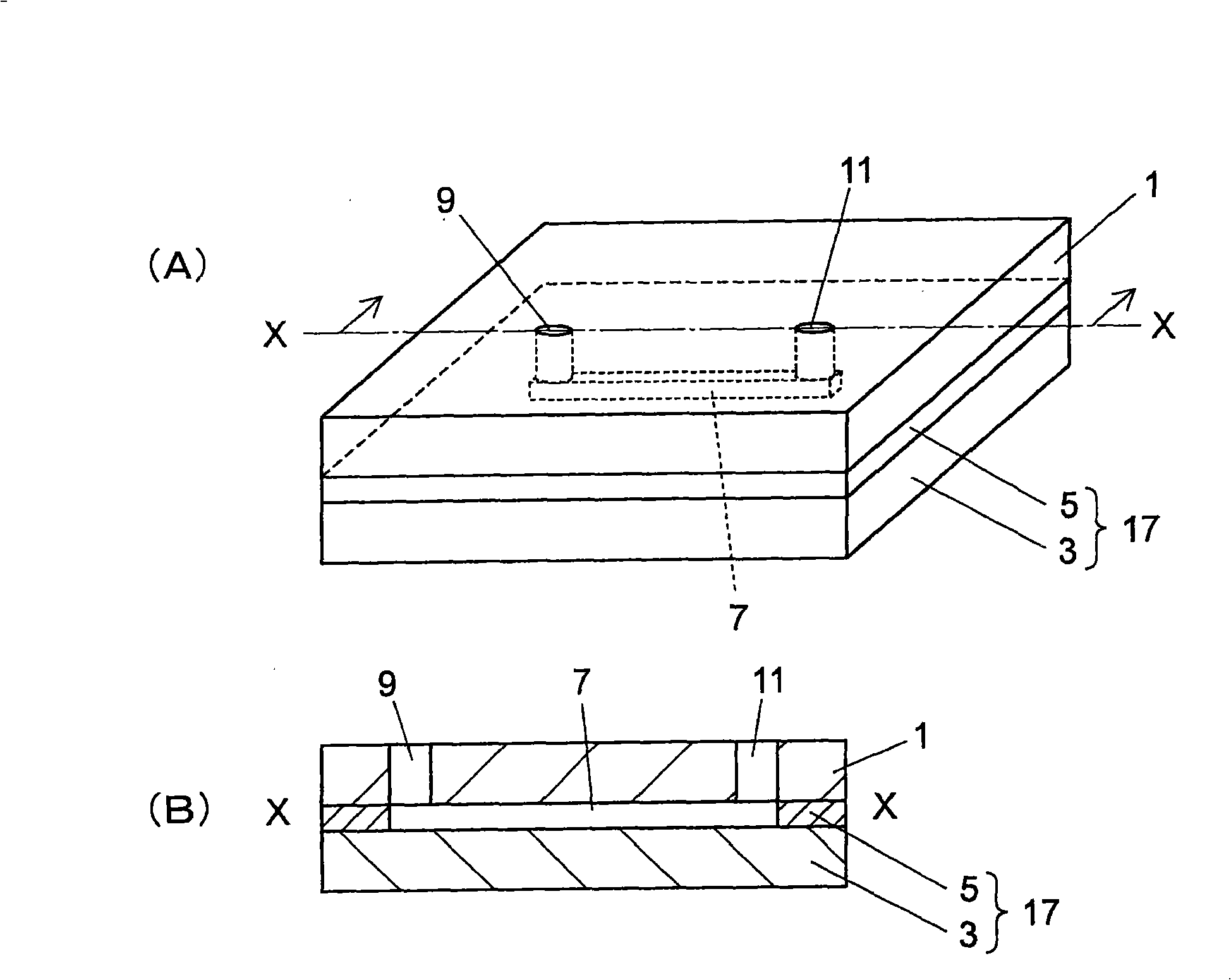

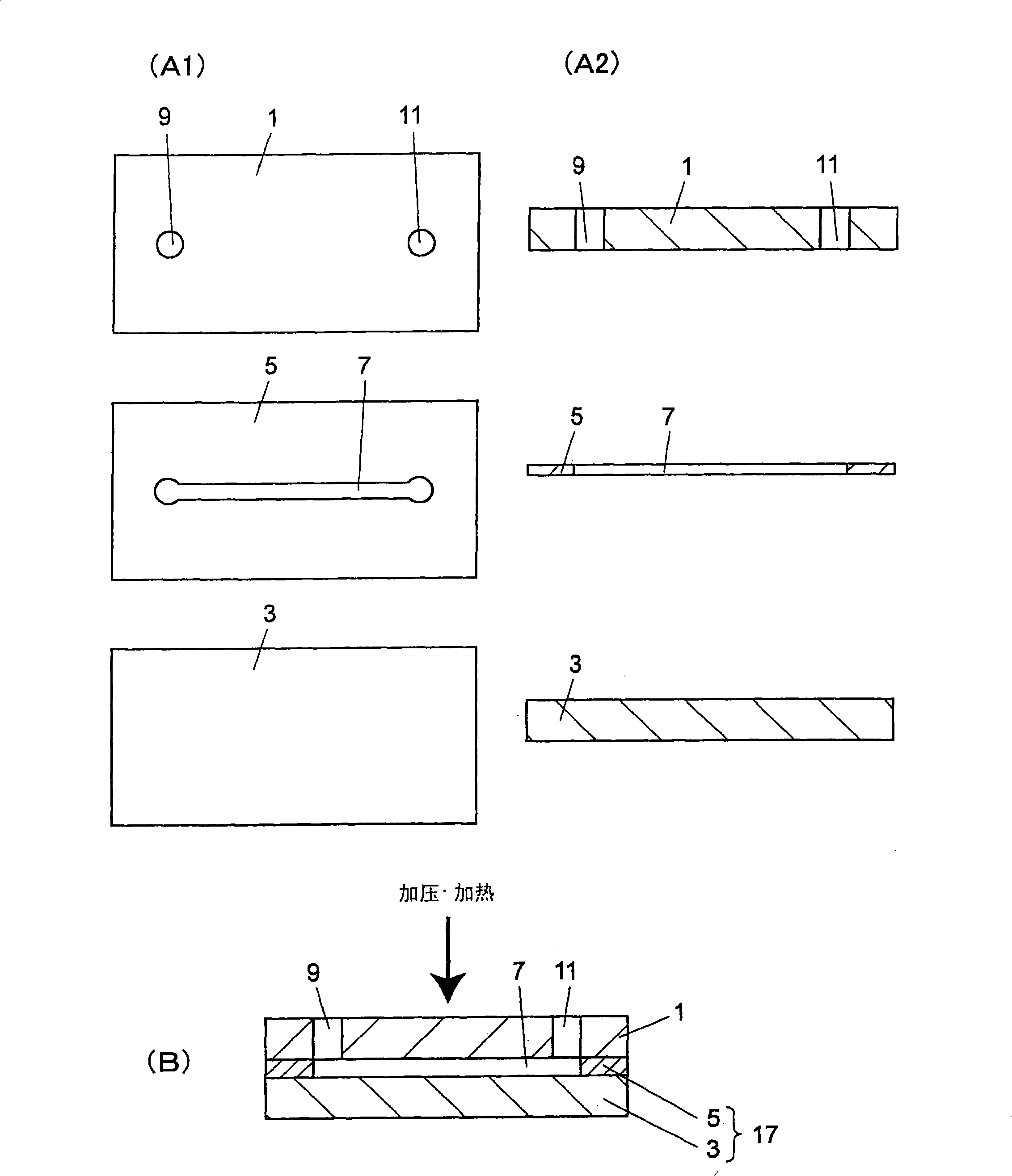

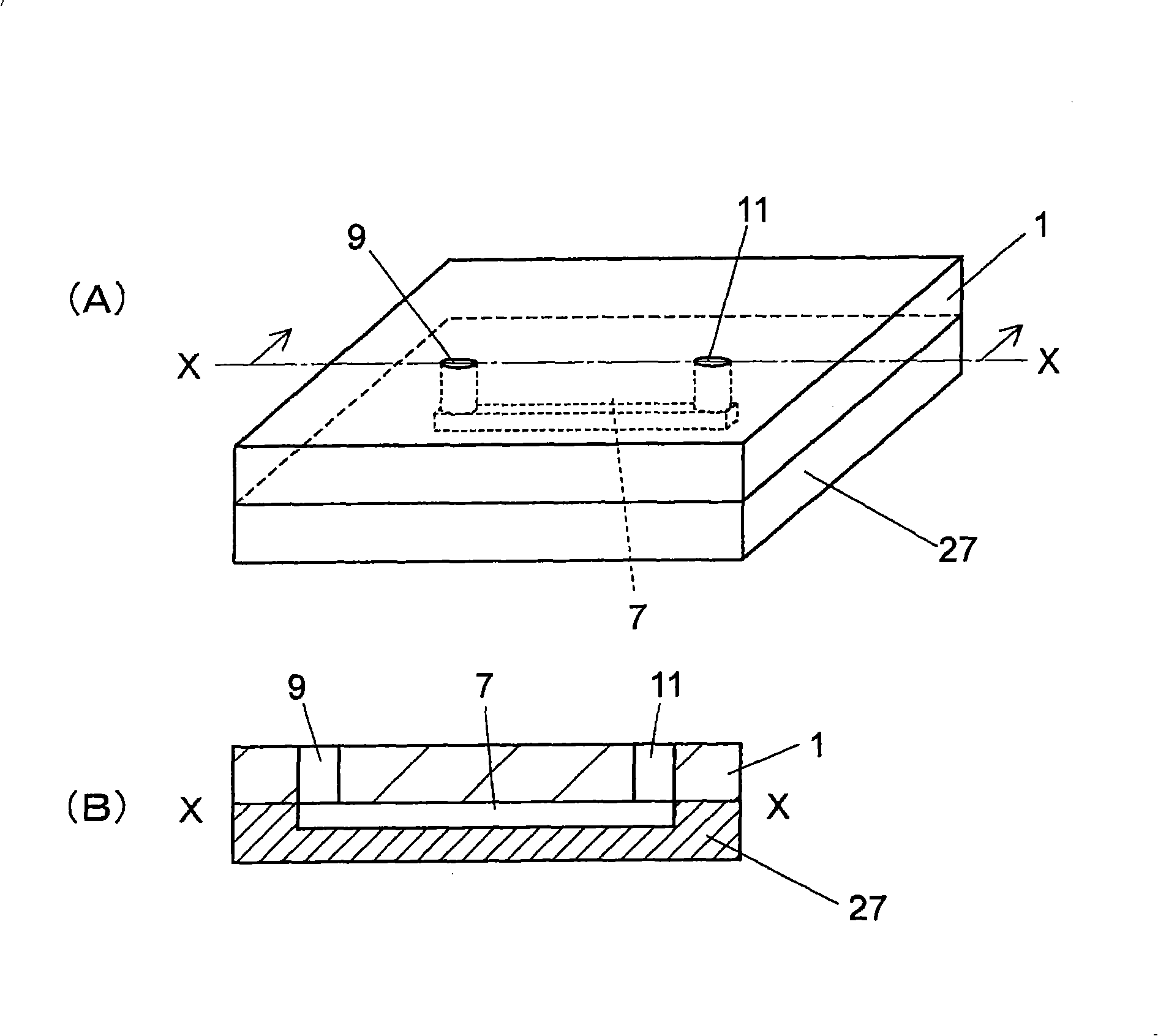

[0043] figure 1 It is a figure which shows the structure of the flow cell of one Example, (A) is a perspective view, (B) is a cross-sectional view taken along line X-X of (A).

[0044]The flow cell of this embodiment is composed of a flat glass substrate 3, an adhesive fluororesin sheet 5 cut and processed with grooves serving as flow paths 7, and through holes for inlet or outlet of fluid formed at positions corresponding to both ends of the groove. The holes 9 and 11 are formed by the glass substrate 1 serving as a cover member, the fluororesin sheet 5 is sandwiched between the glass substrates 1 and 3, and the fluororesin sheet 5 itself is adhesively bonded. The flow path member 17 is constituted by the glass substrate 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com