Drive with an energy store device and method for storing kinetic energy

An energy storage and drive technology, applied in the drive field, can solve problems such as the influence of braking performance, and achieve the effect of increasing the throttling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

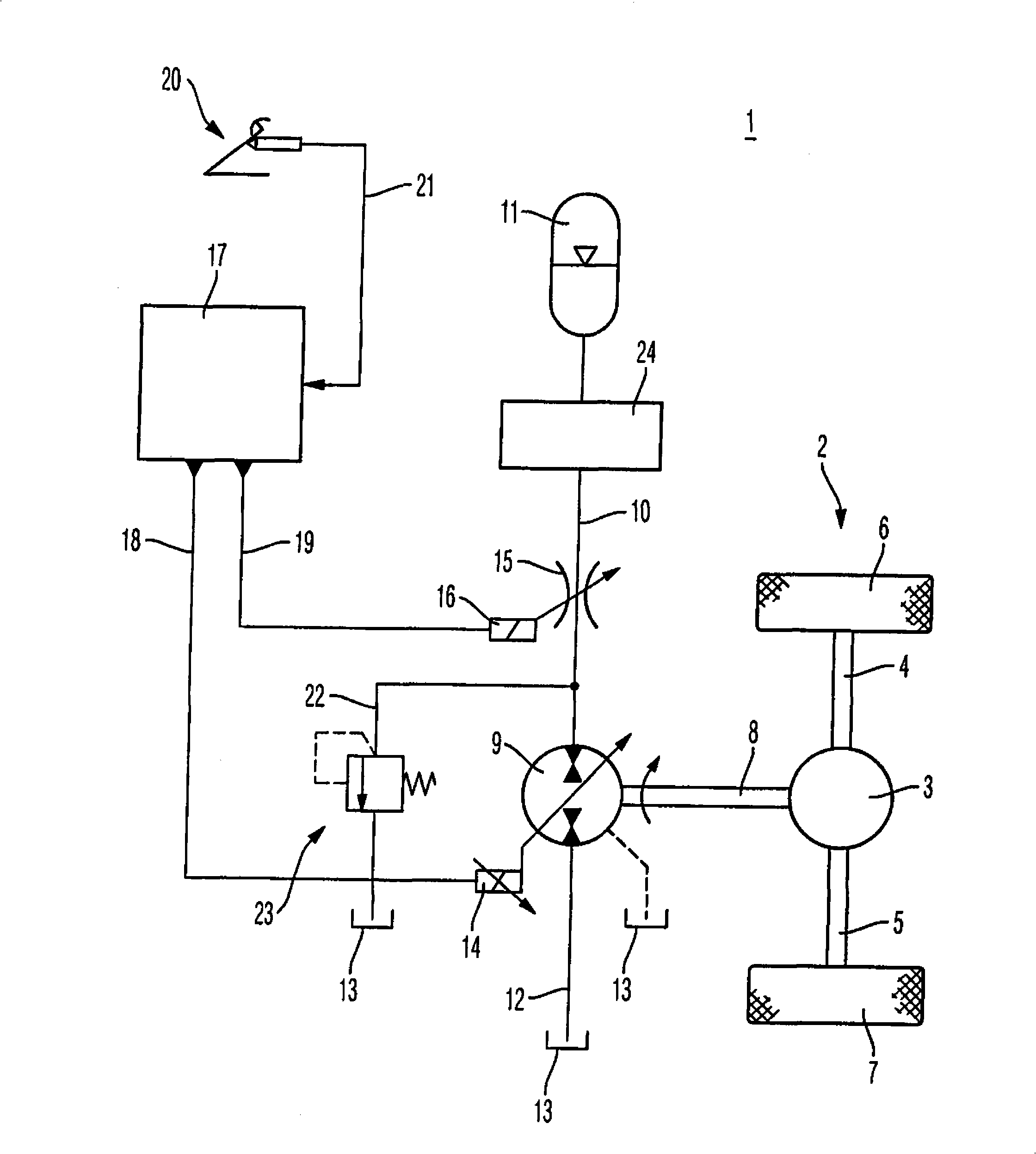

[0013] figure 1 It is a schematic explanatory diagram of the drive 1 according to the present invention. The drive 1 according to the invention is used, for example, to drive a drive shaft 2. The driven drive shaft 2 has a shaft differential 3 which acts on the driven wheels 6, 7 of the vehicle via the first half shaft 4 and the second half shaft 5.

[0014] The drive 1 described is in particular a drive drive of a utility vehicle with a dense drive cycle. For example, in garbage collection vehicles, wheeled excavators, and forklifts, such intensive driving cycles can occur, which involve a large number of braking and then accelerating operations. In order to enable the kinetic energy released during the braking operation to be reused, the drive 1 has an energy storage device. The energy storage device is connected to the drive shaft 2 through a coupling shaft 8. For succinct reasons, the coupling axis 8 is figure 1 Shown in is connected to the rear axle differential 3. However, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com