Method for observing tungsten material product microscopic structure

A microstructure and product technology, applied in the direction of analyzing materials, preparation of test samples, and measuring devices, etc., can solve the problems of fast corrosion, easy generation of oxide film, and inability to improve tissue contrast, etc., and achieve slow corrosion, Easy to control and eliminate the effect of oxide film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

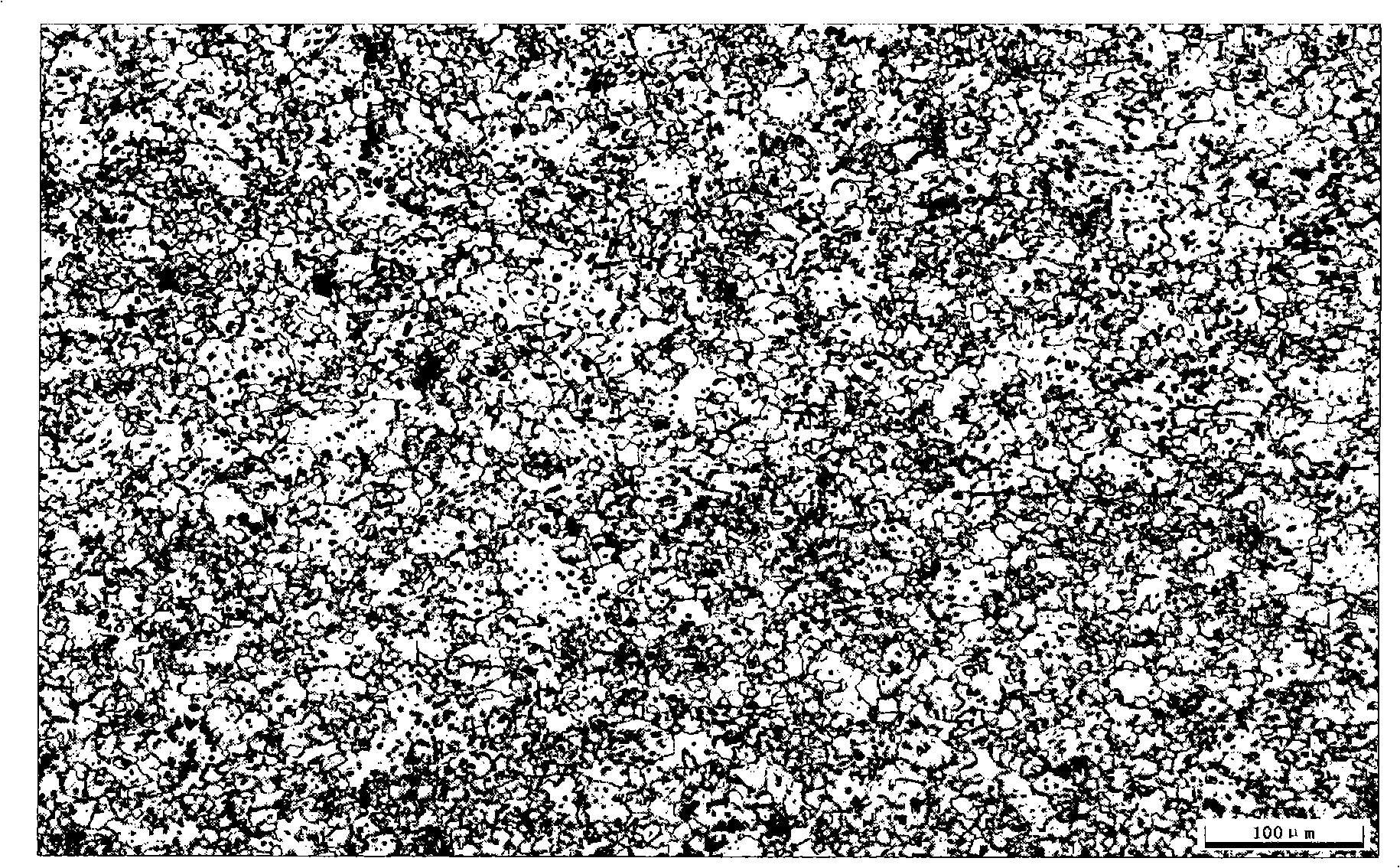

[0018] The raw material is Fw-01 tungsten powder, the average particle size is 4.4 microns, and the tungsten slab is formed by static pressure. The vacuum sintering temperature is 1800°C, and the sintering time is 6 hours. After grinding, grinding and polishing the surface of the tungsten slab, select HNO 3 , HF mixed solution, HNO 3 , The volume ratio of HF is 1:1 or 3:1 to slightly corrode the metallographic surface of the prepared tungsten sample, and then use 10 grams of K 3 Fe(CN) 6 , 10 grams of NaOH and 100 ml of water solution sassafras, the time is about 5s. figure 1 for the microstructure diagram.

Embodiment 2

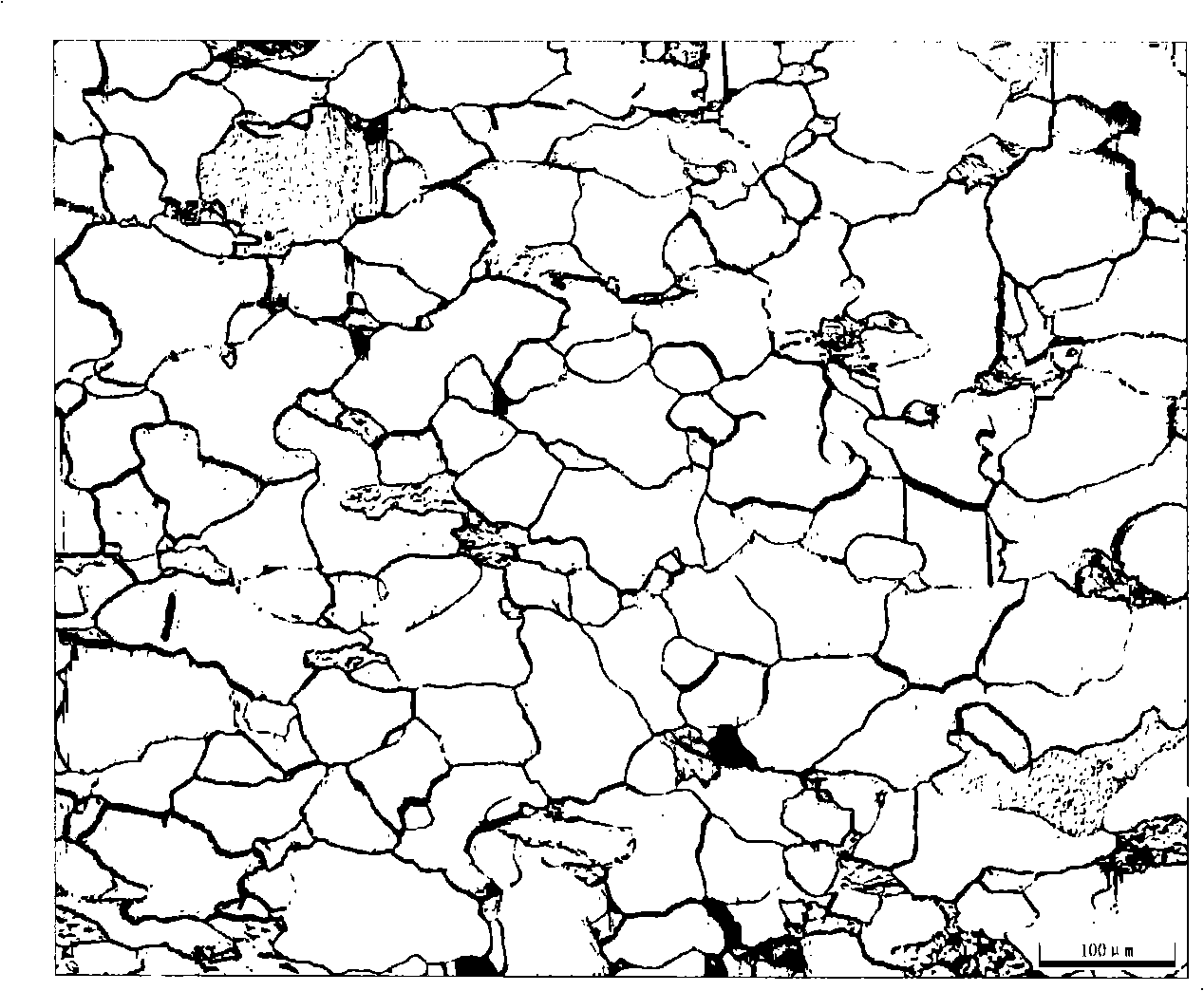

[0020] The tungsten plate with a thickness of 10mm is rolled at high temperature, and the surface of the tungsten plate is ground, ground and polished, and then HNO is selected. 3 , HF mixed solution, HNO 3 , The volume ratio of HF is 3: 1 slightly erodes the metallographic surface of the prepared tungsten sample, and then uses 10 grams of K 3 Fe(CN) 6 , 10 grams of NaOH and 100 ml of water solution sassafras, the time is about 5s. figure 2 Its microstructure diagram.

Embodiment 3

[0022] The tungsten alloy powder is molded at 100MPa, and after holding the pressure for 20s, it is sintered in a sintering furnace at 1500°C and kept for 2 hours to obtain a WNiFe plate with a thickness of 5mm. The surface of the WNiFe plate is ground, ground and polished, and HNO 3 , HF mixed solution, HNO 3 , The volume ratio of HF is 3: 1 slightly erodes the metallographic surface of the prepared tungsten sample, and then uses 10 grams of K 3 Fe(CN) 6 , 10 grams of NaOH and 100 ml of water solution sassafras, the time is about 5s. image 3 Its microstructure diagram.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com