In situ detoxication alcohol fermentation method of ligno-cellulose hydrolysate using single culture

A technology for lignocellulose and ethanol fermentation, which is applied in microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of increasing the cost of ethanol fermentation process complexity, and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2Y7

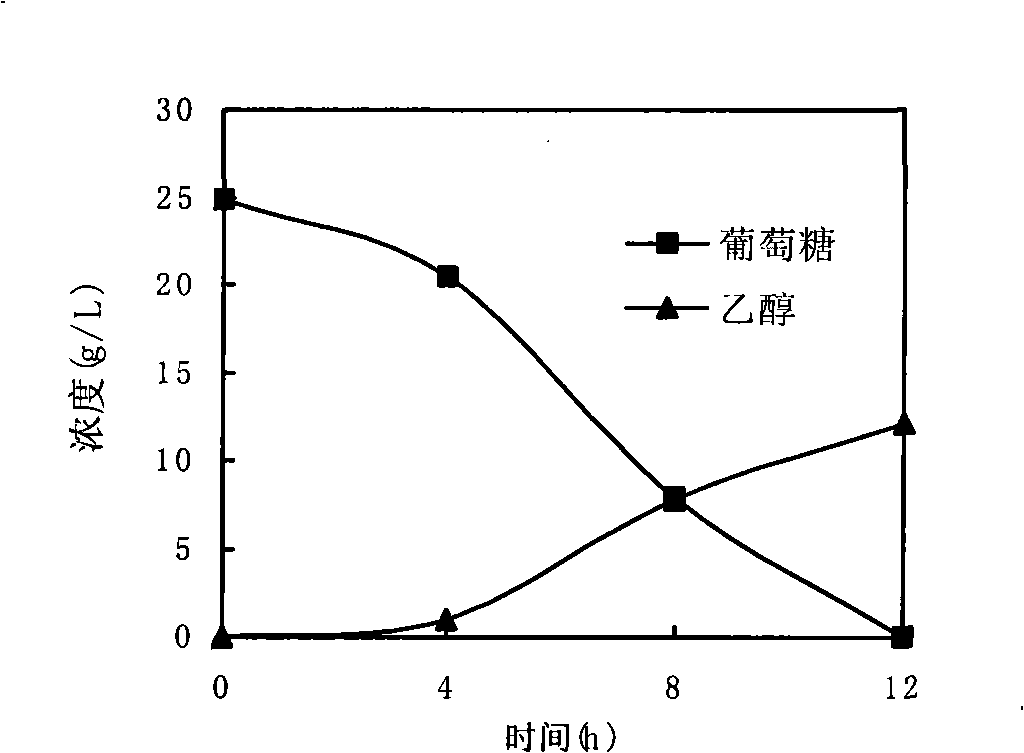

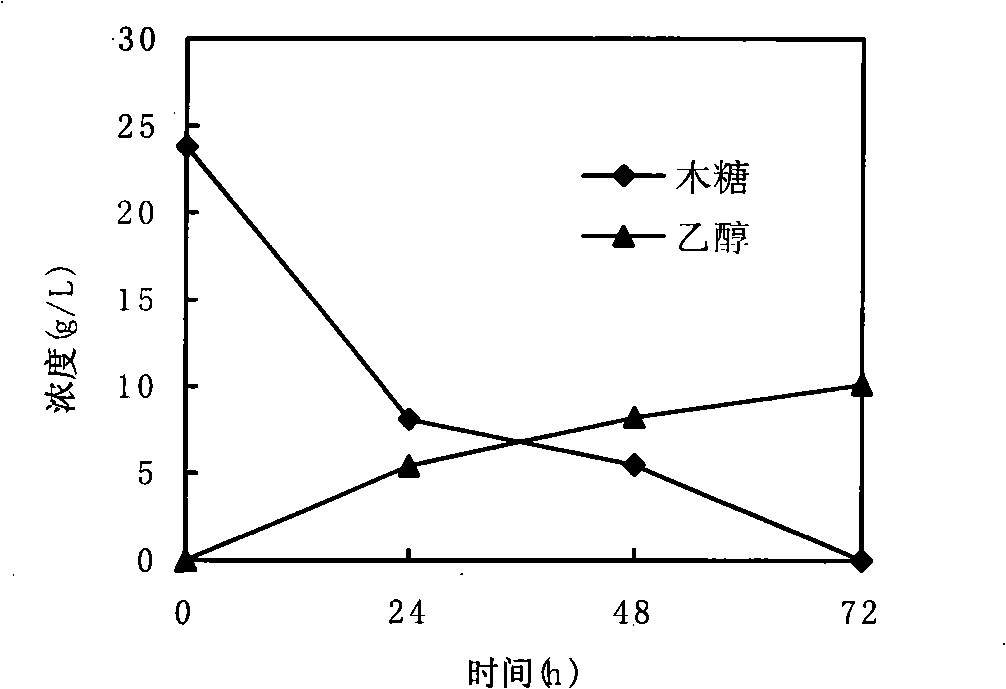

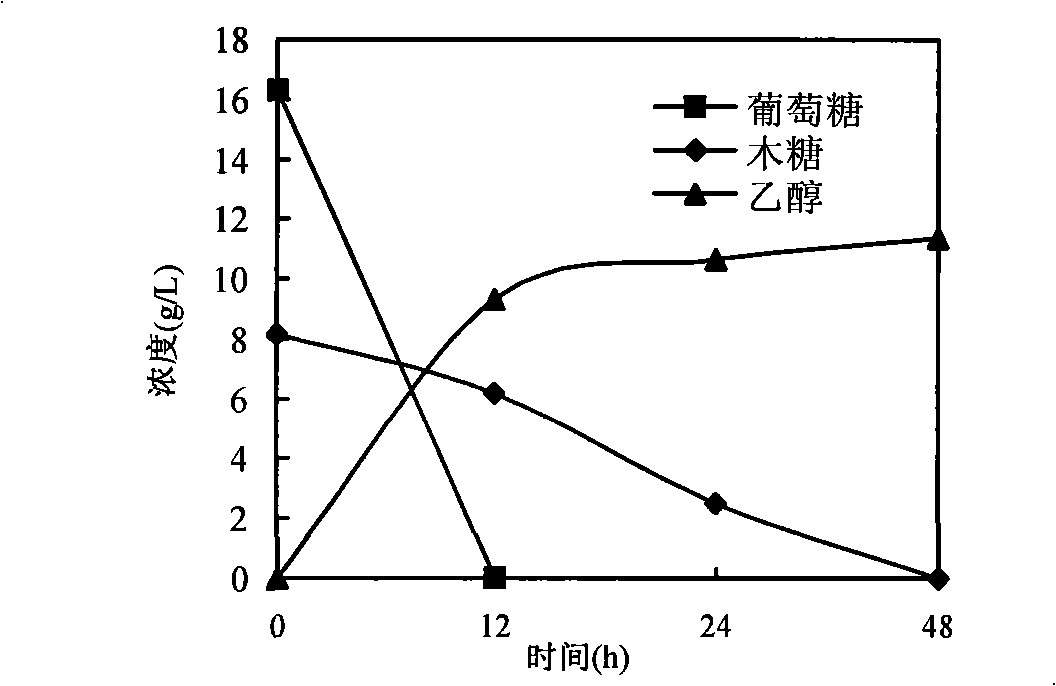

[0031] Able to rapidly utilize xylose and glucose to produce ethanol while being able to tolerate high concentrations of inhibitors. Example 2Y7 Identification of in-situ detoxification ethanol fermentation of lignocellulose dilute acid hydrolyzate

[0032] 1 Materials and methods

[0033] 1.1 Strains

[0034] Strain Pichia.Stipitis Y7

[0035] 1.2 Medium (g / L)

[0036] YPD medium: glucose 20, yeast extract 10, peptone 20, pH 5.0-5.5.

[0037] Fermentation medium: yeast extract 10, peptone 20. In addition, glucose and xylose were added according to different needs (concentration is subject to actual measurement) pH 5.0-5.5.

[0038] 1.3 Dilute acid hydrolyzate of lignocellulose (g / L)

[0039] The dilute acid hydrolyzate of lignocellulose used in this study was provided by East China University of Science and Technology, in which glucose was 44.678, xylose was 24.35, furfural was 1.37, 5-HMF was 0.47, acetic acid was 10, Ca(OH) 2 Adjust the pH of the hydrolyzate to 5.0. ...

Embodiment 3Y7

[0066] Embodiment 3Y7 is to the in-situ detoxification ethanol fermentation of lignocellulose dilute acid hydrolyzate

[0067] 1 seed solution preparation

[0068] Add 100mL YPD liquid medium (glucose 20g / L, peptone 20g / L, yeast extract 10g / L) into a 250mL Erlenmeyer flask, put it into a sterilizing pot at 115°C for 25 minutes for sterilization. Pick a ring of single colony into the Erlenmeyer flask, 150rpm, shaker at 30°C for 12 hours.

[0069] 2 Treatment of hydrolyzate

[0070] Add peptone (20g / L), yeast extract (10g / L) and Ca(OH)2 to the hydrolyzate to adjust the pH to 5.0, and put it into a sterilizing pot at 115°C for 25 minutes to sterilize.

[0071] 3 Fermentation of lignocellulose dilute acid hydrolyzate

[0072] Take 10mL Y7 seed solution (the number of viable bacteria is 8×10 8 pcs / ml~9×10 8 Each / ml) was added to the Erlenmeyer flask equipped with hydrolyzate, 150rpm, shaker and cultured at 30°C.

[0073] 4 analysis methods

[0074] 4.1 Determination of sugar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com