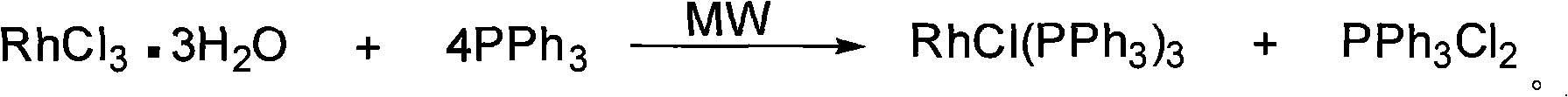

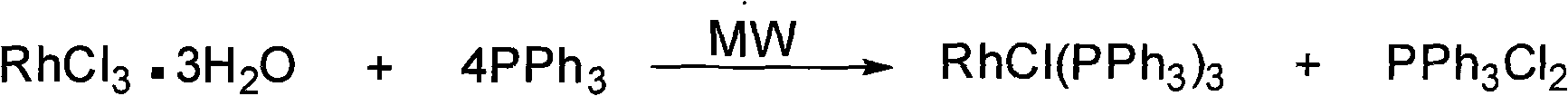

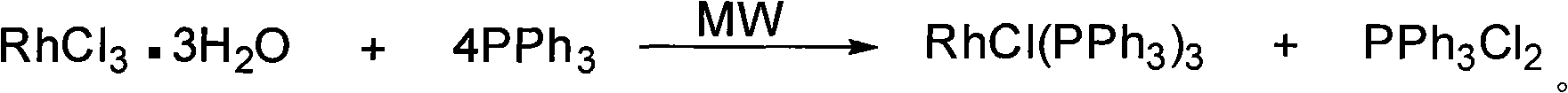

Microwave synthetic method of tri(triphenylphosphine) rhodium chloride

A technology of rhodium trichloride trihydrate and triphenylphosphine, which is applied in the field of microwave synthesis of rhodium trichloride, can solve problems such as complex process routes, and achieve the effects of simplified process flow, high purity, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In a 1L flask equipped with a mechanical stirrer and a reflux condenser, dissolve 10.0g of rhodium trichloride trihydrate in 200ml of 90% ethanol; add 500ml of ethanol solution containing 60g of pretreated triphenylphosphine, place in microwave In the reactor, react under 700W power microwave radiation for 5 minutes to form a large number of dark red crystals; cool to 40°C, filter the product obtained by suction, wash it with 100ml of anhydrous ether, and dry it in vacuum at 50°C for 2 hours to obtain dark red crystals Product, yield 34.7g, yield 98.8%; Elemental analysis: C: 70.30%; H: 5.13%; N: 0%, Rh element content measured by atomic absorption is 11.0%.

Embodiment 2

[0021] The reaction steps are the same as in Example 1, except that the microwave radiation power is 400W, and the reaction time is 20 minutes. The post-treatment operation is the same as in Example 1, and the product yield is 98.4%.

Embodiment 3

[0023] The reaction steps are the same as in Example 1, except that the nitrogen protection is applied, and the reaction time is 5 minutes. The post-treatment operation is the same as in Example 1, and the product yield is 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com