Method for controlling a vehicle equipped with a mechanical servo transmission

A control method and servo controller technology, applied in the direction of transmission control, mechanical equipment, components with teeth, etc., can solve the problem of lengthy and heavy initial calibration of mechanical servo transmission devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

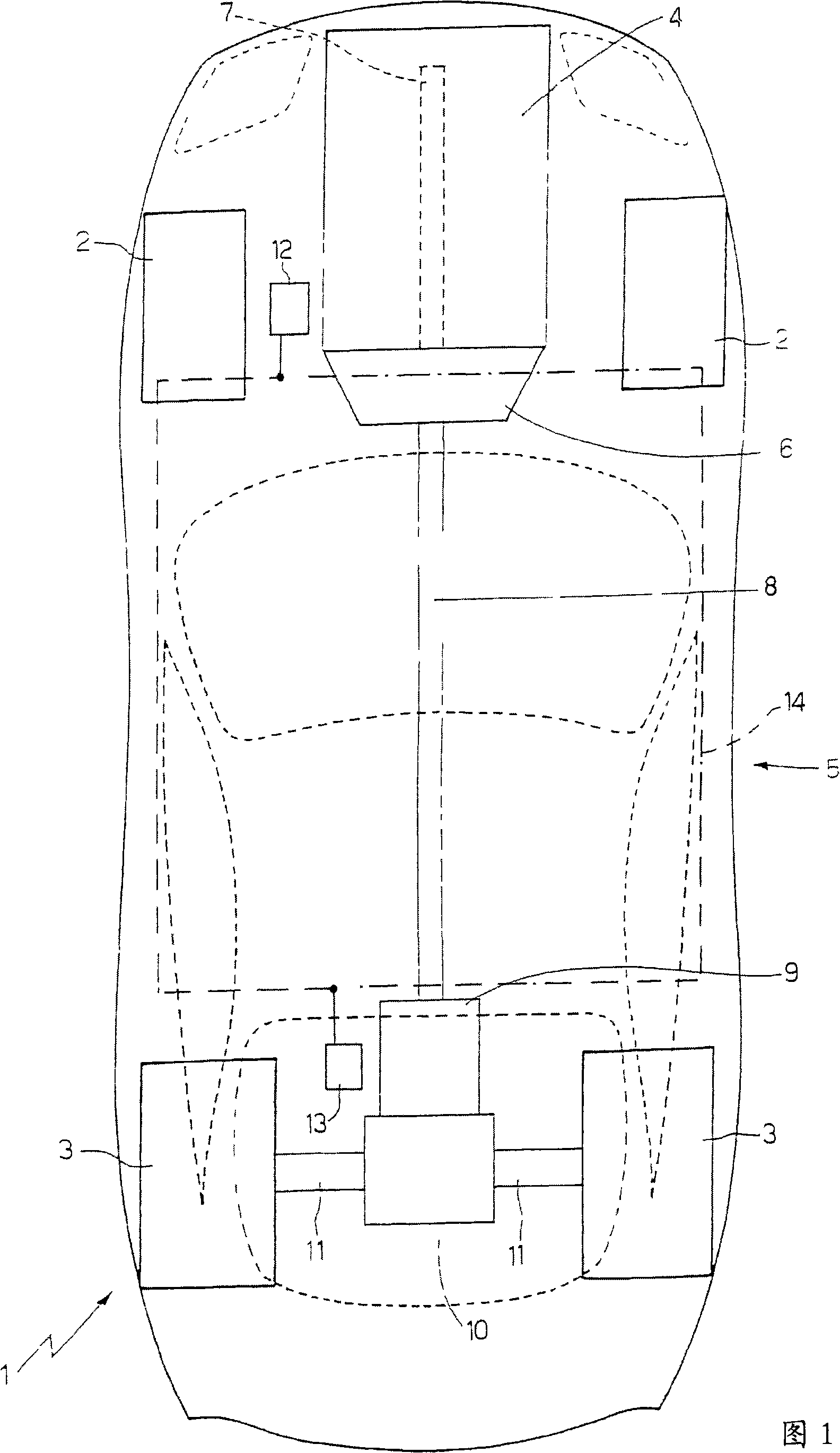

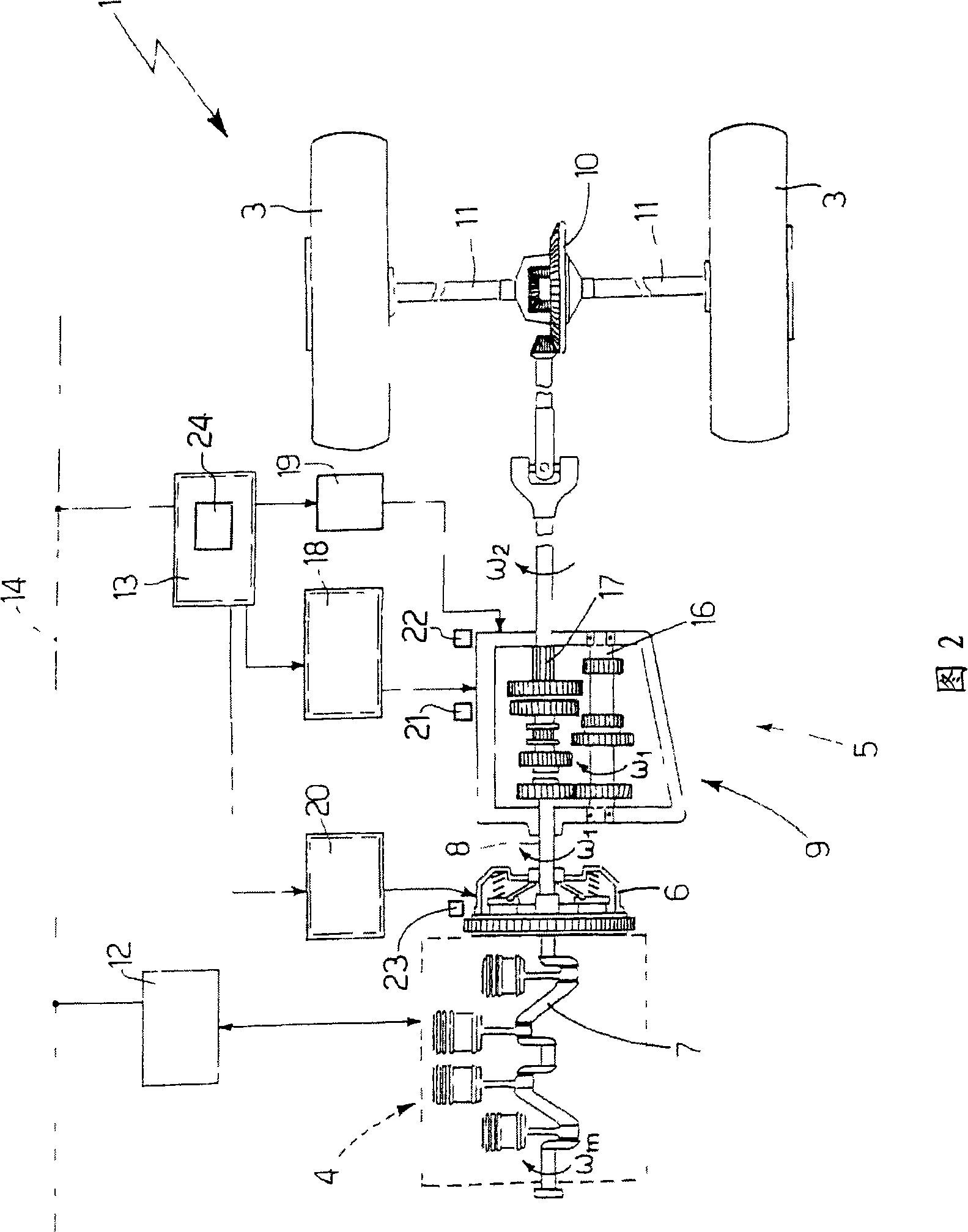

[0024] In FIG. 1 , reference numeral 1 denotes the whole of a motor vehicle provided with two front wheels 2 and two rear drive wheels 3 which receive the torque generated by the internal combustion engine 4 through a servo transmission 5 . The servo transmission 5 comprises a servo clutch 6 housed in a bell fixed relative to the engine 4 and designed to connect the transmission shaft 7 of the engine 4 to a transmission shaft 8 which 8 terminates in a servo transmission 9 arranged on the rear axle. A self-locking differential 10 is connected in cascade to said servo transmission 9, from which a pair of drive shafts 11 extend, each of said drive shafts 11 being opposite to a respective rear drive wheel 3 fixed.

[0025] The automobile 1 comprises an engine control unit 12 (schematically shown), a transmission control unit 13 (schematically shown), and a line 14 bus (BUS) implementing a CAN (Automotive Local Network ) agreement and extended to the entire car1. Both the engine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com