Mask for screen printing and screen printing method using the same

A technology of screen printing and masking, which can be used in screen printing, screen printing machines, printed circuits assembled with electrical components, etc., and can solve problems such as low quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, a detailed description will be given of the present invention with reference to the accompanying drawings.

[0030] In the present invention, there is provided a new screen mask having a structure that provides uniform conditions for board separation regardless of the position of the substrate and is not affected by shearing at the time of board separation. Deformation of the solder paste due to shear stress.

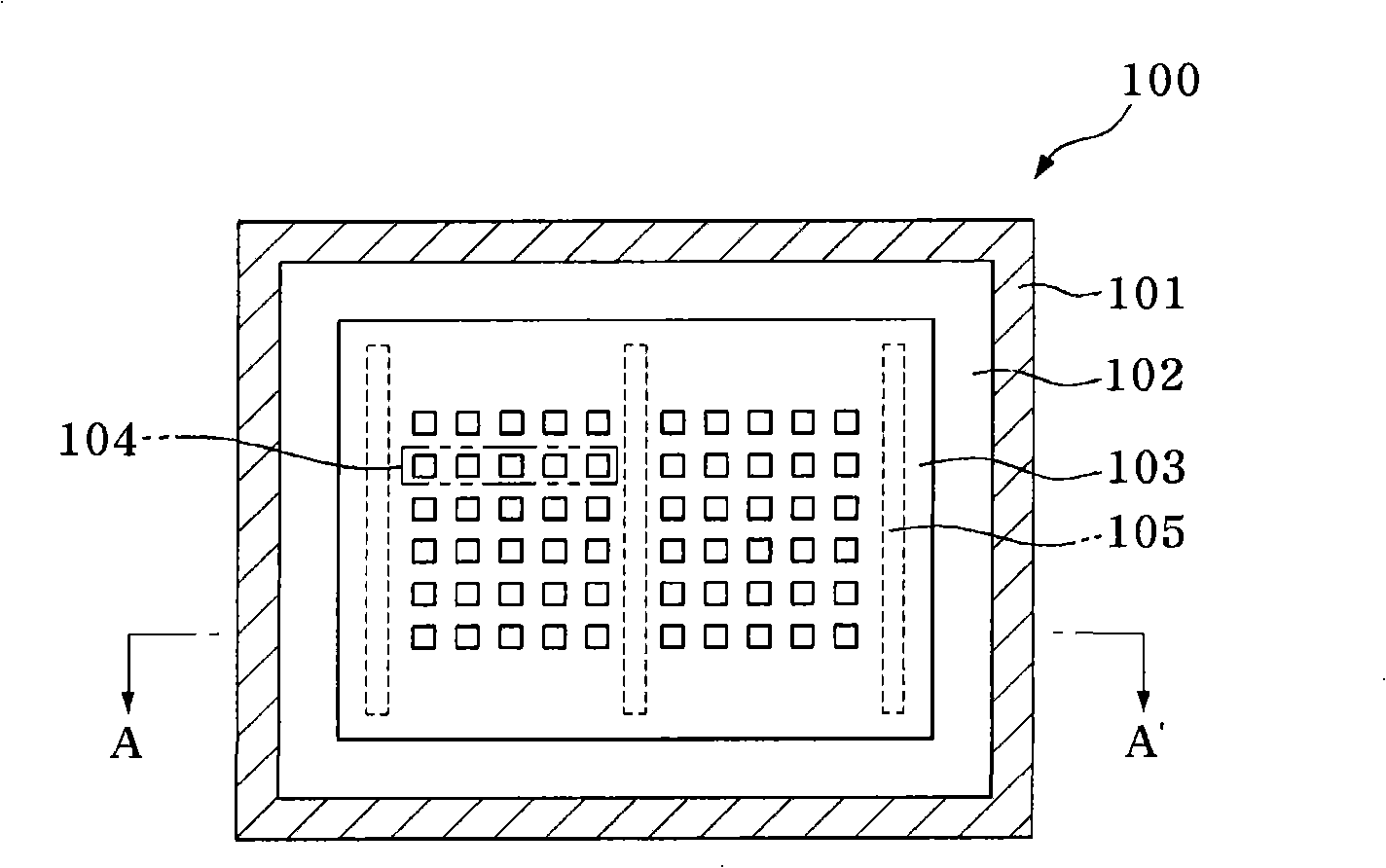

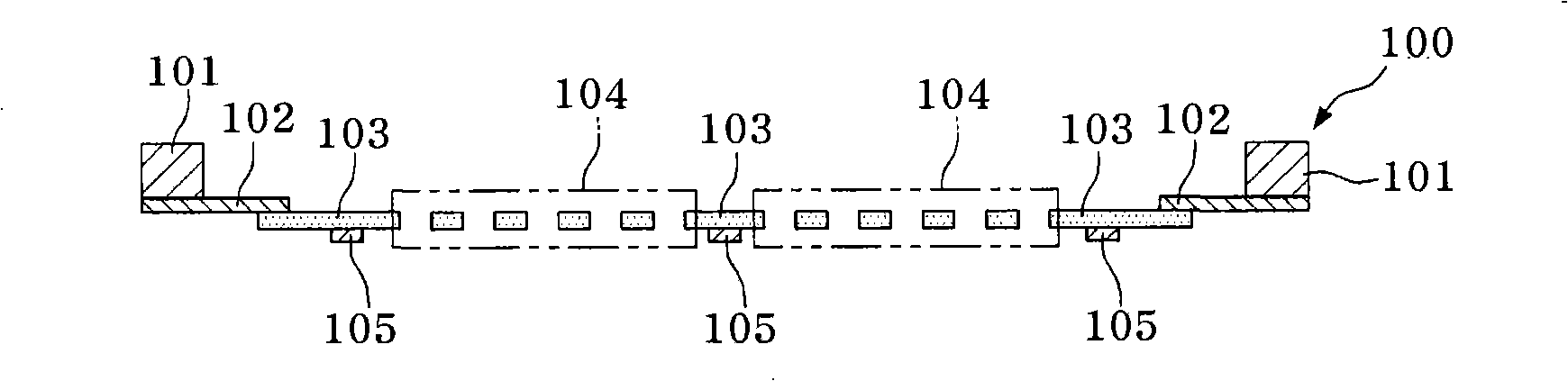

[0031] figure 1 is a top view illustrating a mask for screen printing according to the present invention, and figure 2 is along figure 1 A cross-sectional view taken along the line A-A'.

[0032] refer to figure 1 and figure 2 , the mask 100 for screen printing according to the present invention includes: a mask body composed of a plurality of pattern areas 104 having holes for screen printing and a peripheral area 103 surrounding the outside of the pattern areas; and protrusions 105 , formed in the peripheral region 103 on the backside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com