Cantalever horizontal fixed fixture and continuous solidifying device using the fixture

A technology for fixing tooling and curing devices, which is applied in applications, household appliances, and other household appliances. It can solve problems that affect the performance and appearance quality of the resin matrix of the product, unstable product appearance quality, and inconsistent resin curing performance. Stable and reliable product performance, improved appearance quality, uniform curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

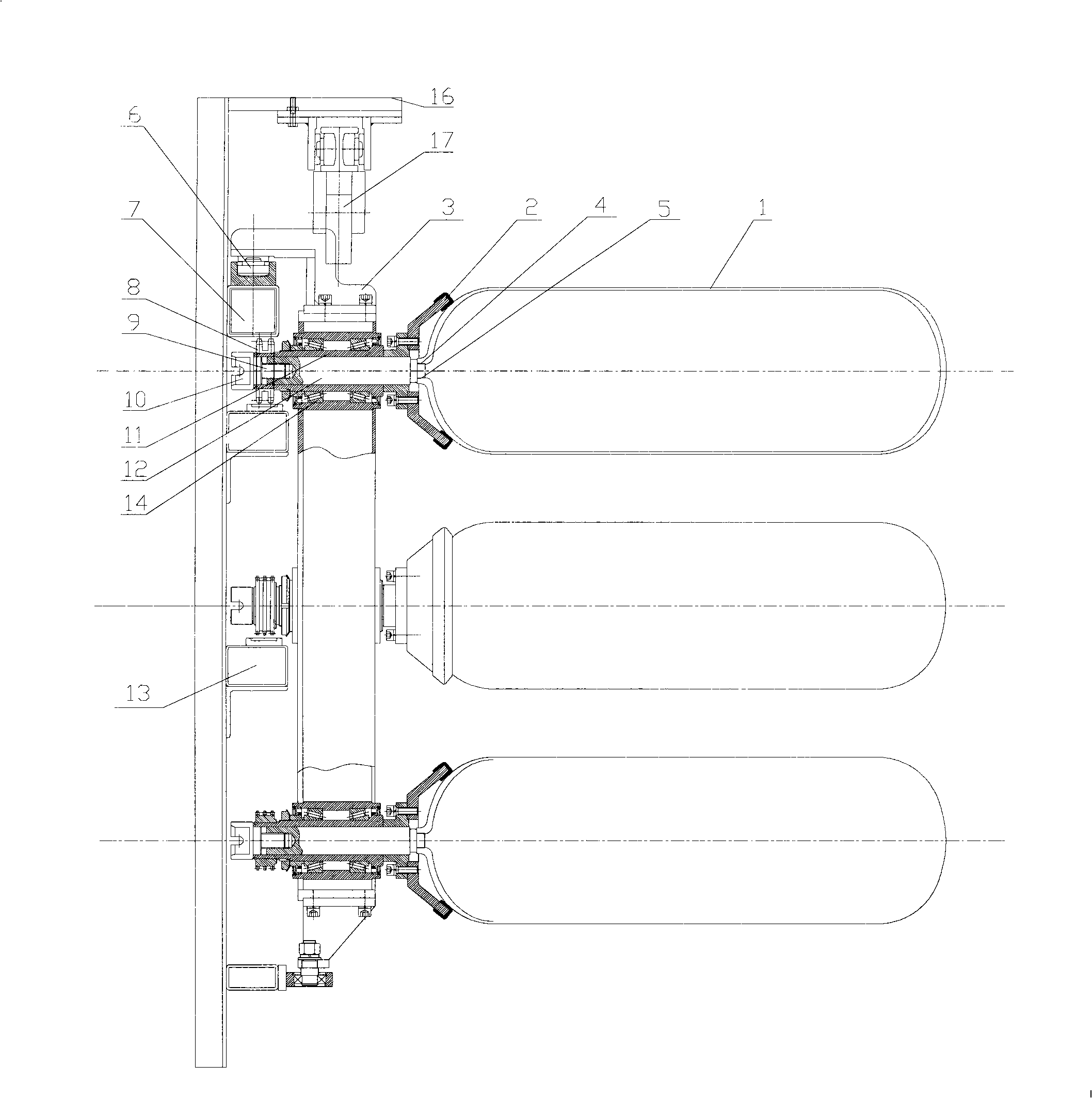

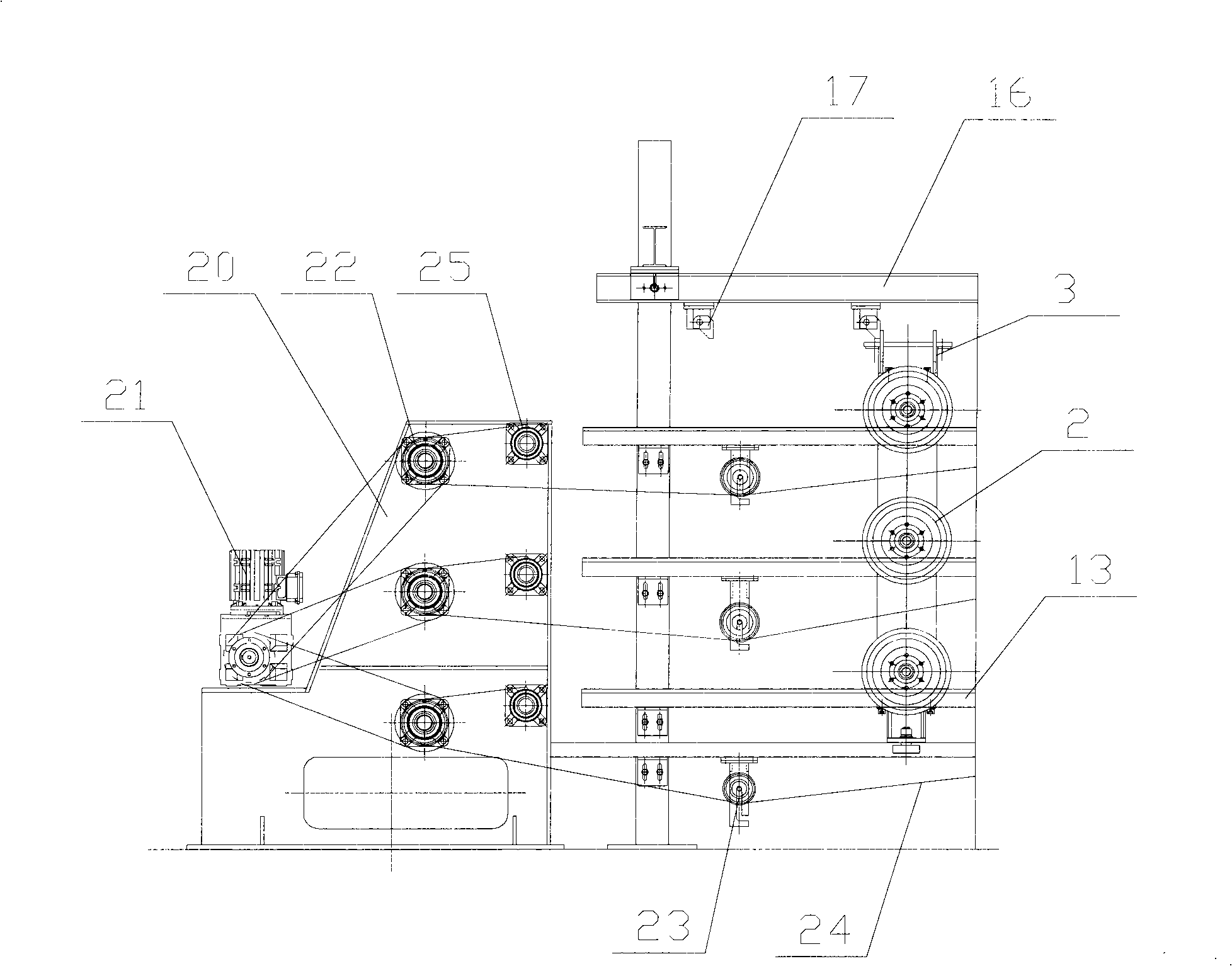

[0036] The invention discloses a cantilever horizontal fixing tool, such as figure 1 As shown, it includes a connecting rod 12, one end of the connecting rod 12 is provided with an external thread 5, and the external thread 5 cooperates with the internal thread 4 at the bottle mouth of the gas cylinder liner 1. After the connecting rod 12 is threadedly connected with the inner container 1, it passes through the hollow guide sleeve 11 horizontally. One end of the guide sleeve 11 is abutted against a support sleeve 2, and the other side of the support sleeve 2 is abutted against. Lean against the periphery of the liner 1 placed horizontally. The support sleeve 2 is a hollow boss with a circular cross-section, and the cross-section of the maximum diameter of the support sleeve 2 matches the outer peripheral shape of the inner container 1 . Certainly, the support sleeve 2 may also be in other forms, such as a chuck shape similar to a lathe, etc., as needed.

[0037] Both the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com