Temperature adjustment coating and preparation thereof

A coating and temperature adjustment technology, applied in the direction of coating, latex paint, etc., can solve the problems of non-appearance, ineffective use of phase change potential, external leakage of phase change materials, etc., to achieve pollution prevention, stable adjustment of temperature range, high phase change The effect of changing enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The paint used in this embodiment is common paint, and the organic-inorganic composite phase change material is expanded perlite composite paraffin prepared by the above method.

[0037] Temperature adjustment coating preparation process:

[0038] Raw materials for producing coatings (all are commonly used raw materials in coating production, commercially available products):

[0039] Ingredients Mass (g)

[0040] water 200

[0041] Cellulose 2.5

[0042] PH regulator AMP-95 1

[0043] Propylene Glycol 5

[0044] Dispersant DP-270 2

[0045] Defoamer NXZ 8

[0046] Kaolin 100

[0047] Heavy calcium powder 150

[0048] Talc 35

[0049] Pure acrylic emulsion 100

[0050] Vinegar Acrylic Emulsion 70

[0051] Alcohol ester dodeca 2.5

[0052] Antifungal agent HF 4

[0053] Get 34 grams (5% of coating weight) by 1) the expanded perlite-octadecane that prepares, stir after mixing with 34 grams of pure acrylic emulsion;

[0054]Weigh water according to the requir...

Embodiment 2

[0059] The coating used in this embodiment is an anti-corrosion coating, and the organic-inorganic composite phase change material is attapulgite-composited octadecane (prepared from 3).

[0060] The preparation process is:

[0061] Raw materials for producing coatings (all are commonly used raw materials in coating production, commercially available products):

[0062] Ingredients Mass (g)

[0063] water 220

[0064] Cellulose 2.5

[0065] PH regulator AMP-95 1

[0066] Propylene Glycol 5

[0067] Dispersant DP-270 2

[0068] Defoamer NXZ 8

[0069] Kaolin 100

[0070] heavy calcium 150

[0071] Talc 35

[0072] Pure acrylic emulsion 100

[0073] Silicone acrylic emulsion 100

[0074] Alcohol ester dodeca 2.5

[0075] Antifungal agent HF 4

[0076] Functional components: Take 42 grams (6% of the paint weight) of attapulgite compound octadecane, mix it with 42 grams of silicone acrylic emulsion and stir evenly;

[0077] According to the method of Example 1, the r...

Embodiment 3

[0084] In this example, an organic-inorganic composite phase change material is added to the existing paint.

[0085] The preparation process is:

[0086] Paint: cbma common interior wall paint (commercially purchased)

[0087] Functional component: expanded perlite-liquid paraffin / octadecane (prepared from 2). Get 40 grams (5% of coating weight), mix with equal amount of pure acrylic emulsion (40 grams) and stir evenly;

[0088] Add 80 grams of prepared functional components and 40 grams of pure water into 800 grams of paint, and stir until the mixture is uniform to obtain a modified temperature-adjusted paint for ordinary paint.

[0089] Use the same method as Example 1 to carry out the performance test, the result: after standing for 24 hours, the coating does not have caking and precipitation;

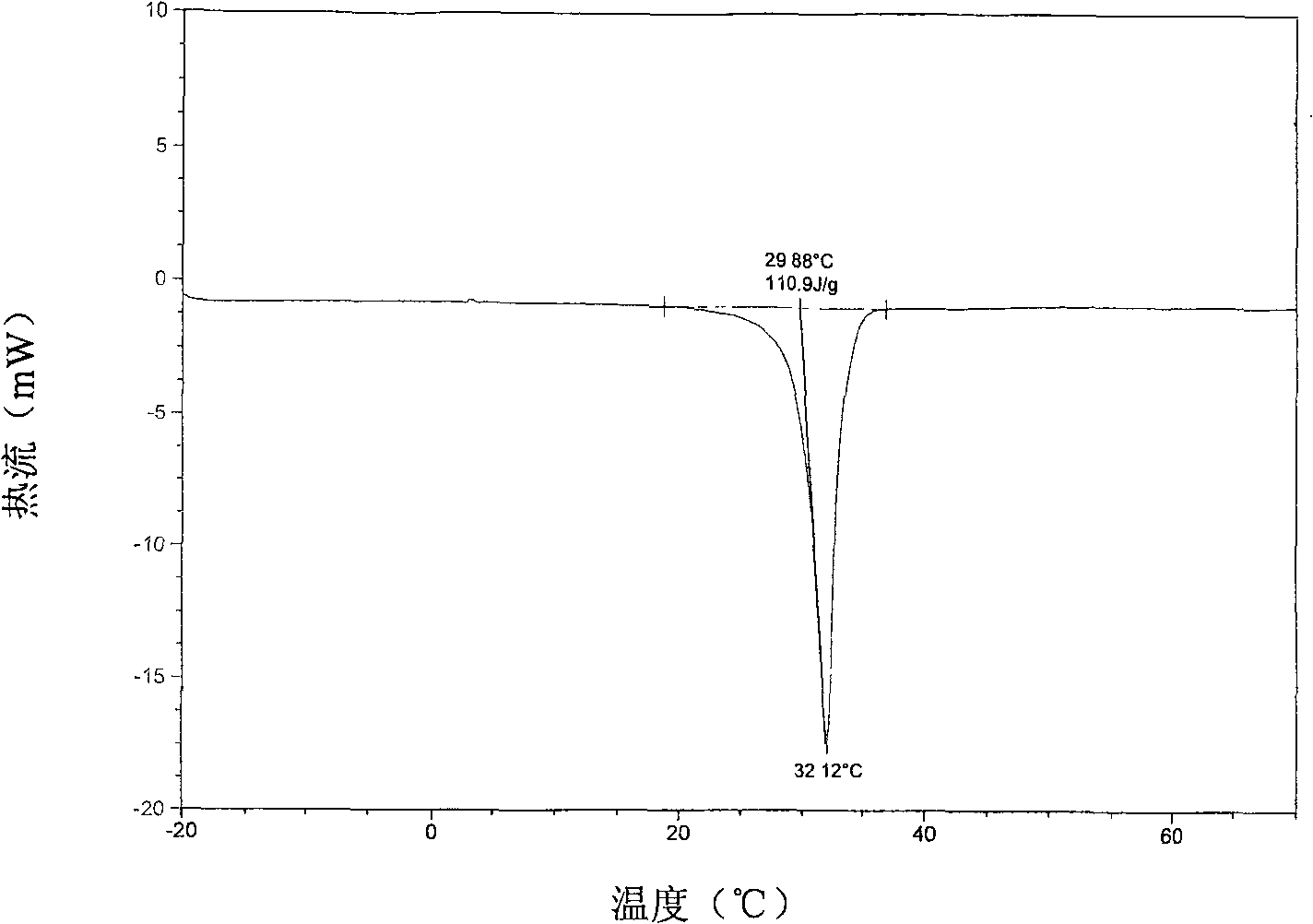

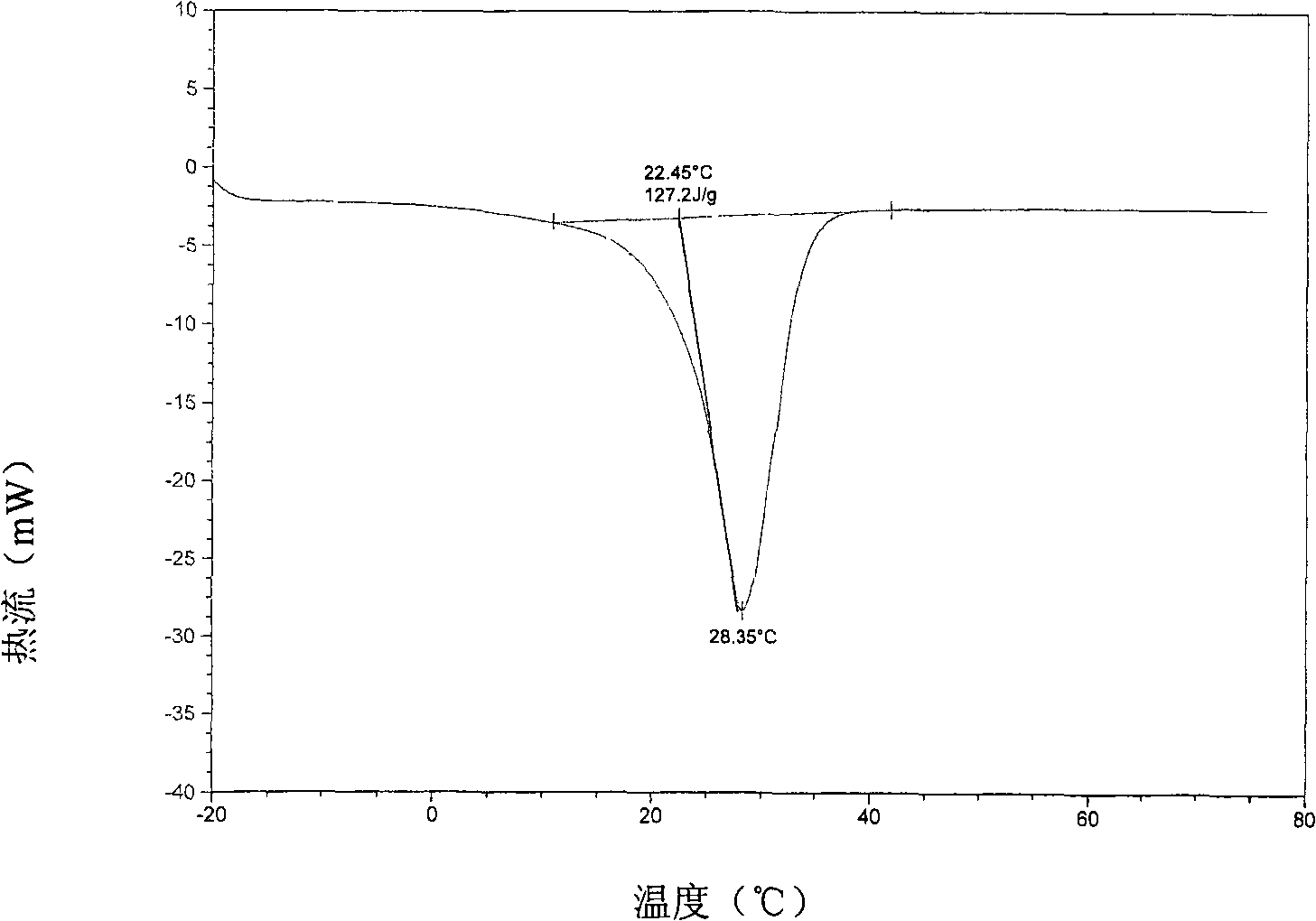

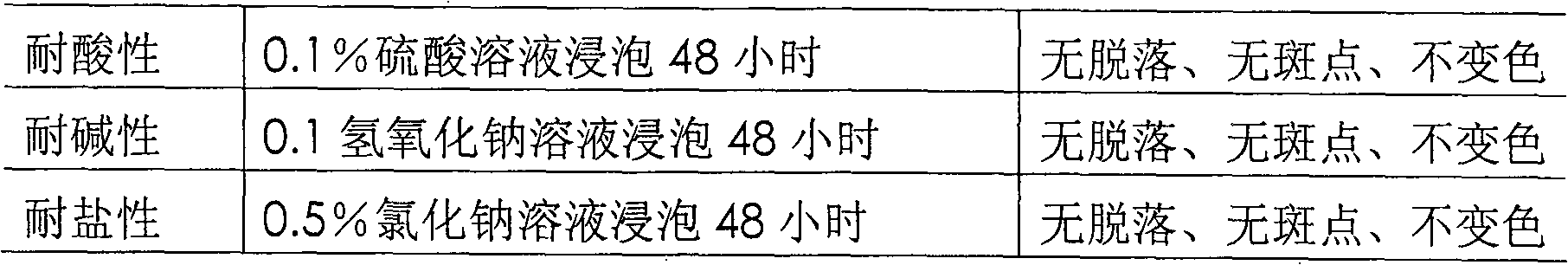

[0090] Temperature adjustment function of coating: The test result of differential scanning calorimeter shows that this coating has obvious phase change material endothermic pea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com