Ethylene apparatus caustic wash tower butter inhibitor and use method thereof

A butter inhibitor and ethylene device technology, applied in chemical instruments and methods, chemical change-inhibiting compositions, organic chemistry, etc., can solve problems such as ineffective effects, prolong operation period, reduce environmental pollution, and achieve significant economic benefits and the effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

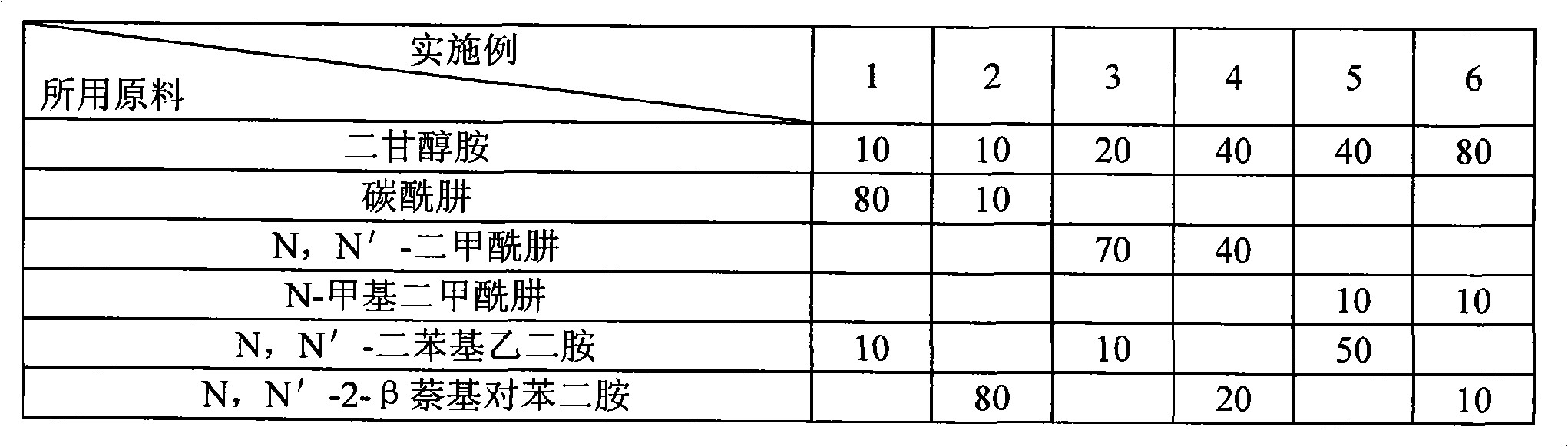

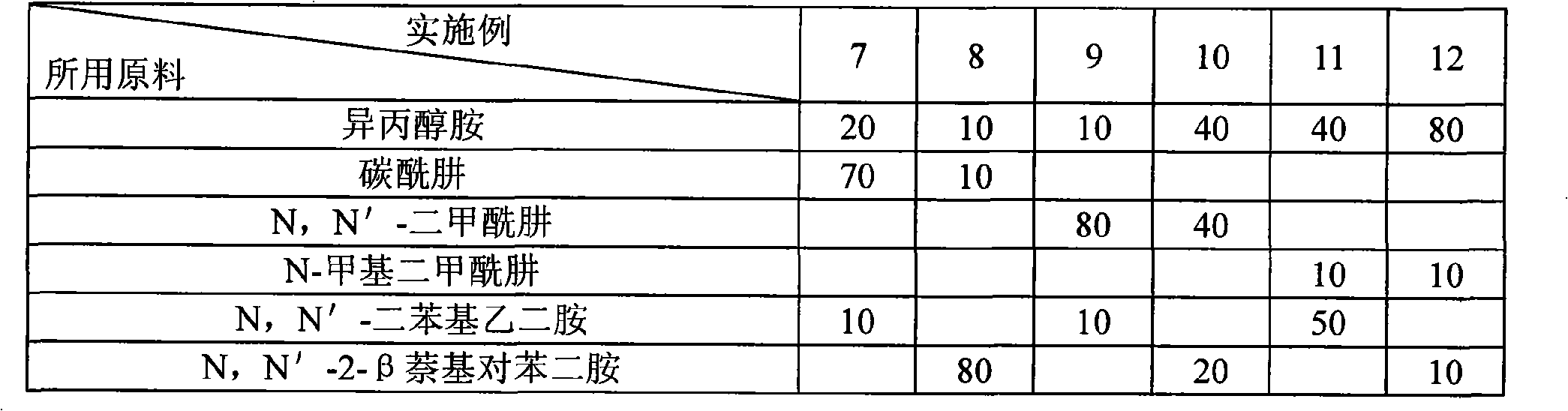

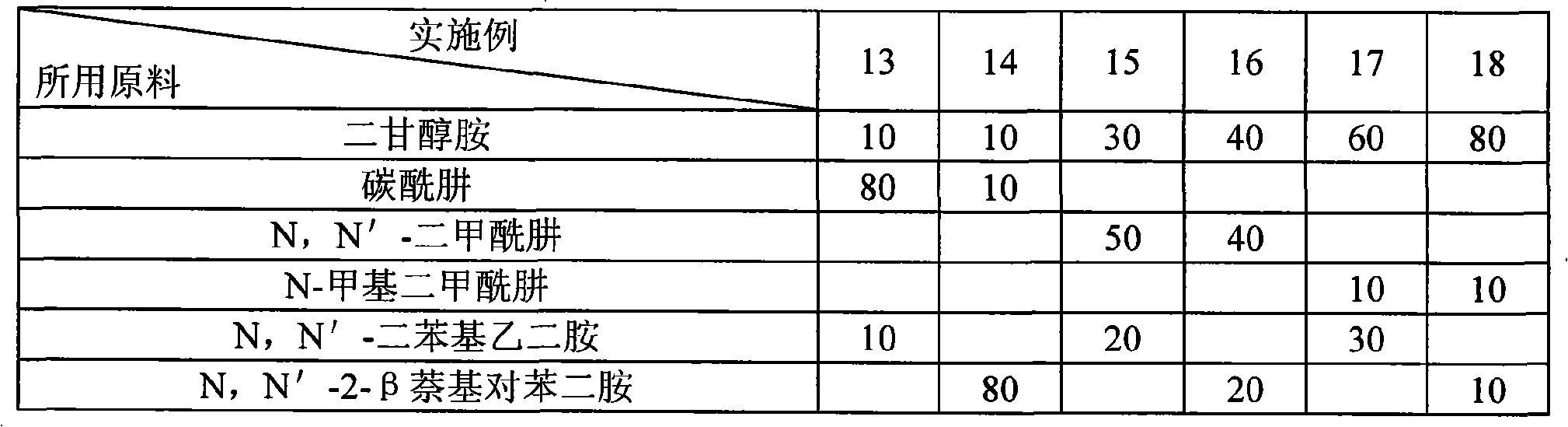

Method used

Image

Examples

Embodiment 19

[0023] The alkali scrubber butter inhibitor of example 1 is applied to the alkali scrubber simulation device of the ethylene plant, wherein the cracking raw material is naphtha, and the total yield of ethylene, propylene and butadiene in the cracked gas is 51.4%, and the simulated alkali scrubber is weak The concentration of lye (NaOH solution) in the alkali section is 2%, and the concentration of lye (NaOH solution) in the strong alkali section is 5%. The butter inhibitor is continuously injected in the strong and weak alkali circulation line by using an electromagnetic pump, and the injection concentration is 500ppm. After the device has been running for 24 hours, the COD value of the lye in the weak base section is 12459mg / L using the test method of GB8978-1996.

Embodiment 20

[0025] The alkali scrubber butter inhibitor of example 2 is applied to the alkali scrubber simulation device of the ethylene plant, wherein the cracking raw material is naphtha, and the total yield of ethylene, propylene and butadiene in the cracked gas is 51.4%, and the simulated alkali scrubber is weak The concentration of lye (NaOH solution) in the alkali section is 2%, the concentration of lye (NaOH solution) in the strong alkali section is 5%, and the butter inhibitor is continuously injected in the strong and weak alkali circulation line by using an electromagnetic pump, and the injection concentration is 450ppm. After the device has been running for 24 hours, the COD value of the lye in the weak base section is tested by the test method of GB8978-1996 to be 13001mg / L.

Embodiment 21

[0027] The alkali scrubber butter inhibitor of example 3 is applied to the alkali scrubber simulation device of the ethylene plant, wherein the cracking raw material is naphtha, and the total yield of ethylene, propylene and butadiene in the cracked gas is 51.4%, and the simulated alkali scrubber is weak The concentration of lye (NaOH solution) in the alkali section is 2%, and the concentration of lye (NaOH solution) in the strong alkali section is 5%. The butter inhibitor is continuously injected into the strong and weak alkali circulation lines by using an electromagnetic pump, and the injection concentration is 400ppm. After the device has been running for 24 hours, the COD value of the lye in the weak base section is 13577mg / L using the test method of GB8978-1996.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com