Shaving board producing method

A manufacturing method and particleboard technology, applied in the direction of manufacturing tools, pretreatment of molding materials, adhesive types, etc., can solve the problems of shortened service life, furniture performance and aesthetic decline, etc., to achieve low production cost, water absorption thickness expansion Efficient and stable, stable and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

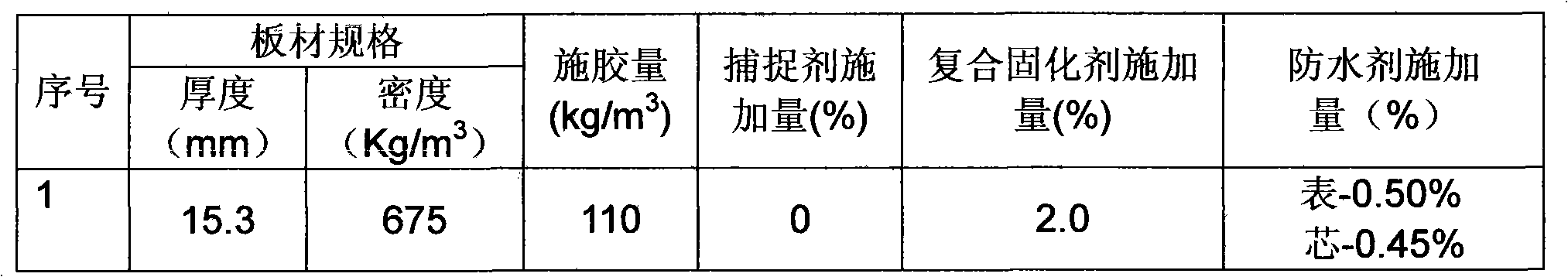

Embodiment 1

[0027] Example 1 The method of the present invention is used to produce an E0 grade particleboard board with low water absorption thickness expansion.

[0028] The usual manufacturing method of particleboard is: the raw materials are sliced, planed and dried, and the qualified surface layer and core layer shavings are screened out, and enter the surface layer and core layer silos respectively, and the layer and core layer shavings that meet the process requirements pass through their respective scrapers. The conveyor is sent to the glue mixing machine, and a certain amount of urea-formaldehyde resin, composite curing agent, formaldehyde scavenger and waterproofing agent are input, and the glue is mixed (sizing) in the glue mixer respectively; Shaped, then cooled, stacked, sanded, cut and inspected, and finally packaged for delivery.

[0029] The production method specifically comprises the steps:

[0030] A) using miscellaneous wood as the main raw material, through slicing, ...

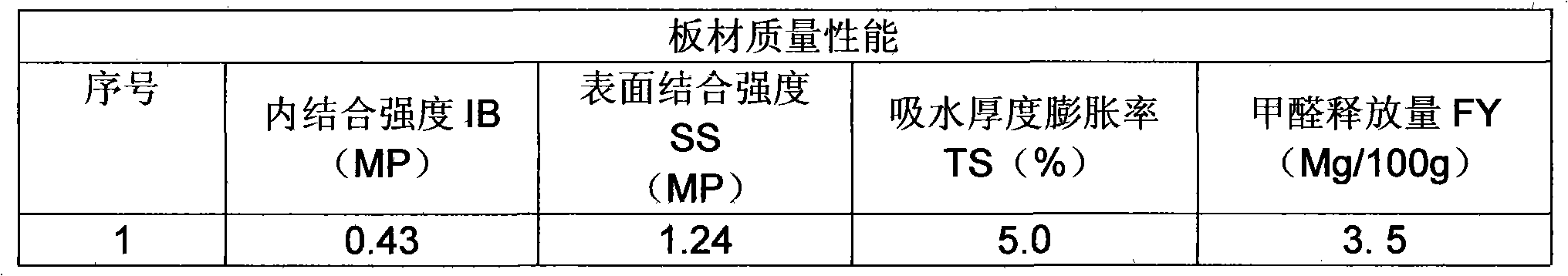

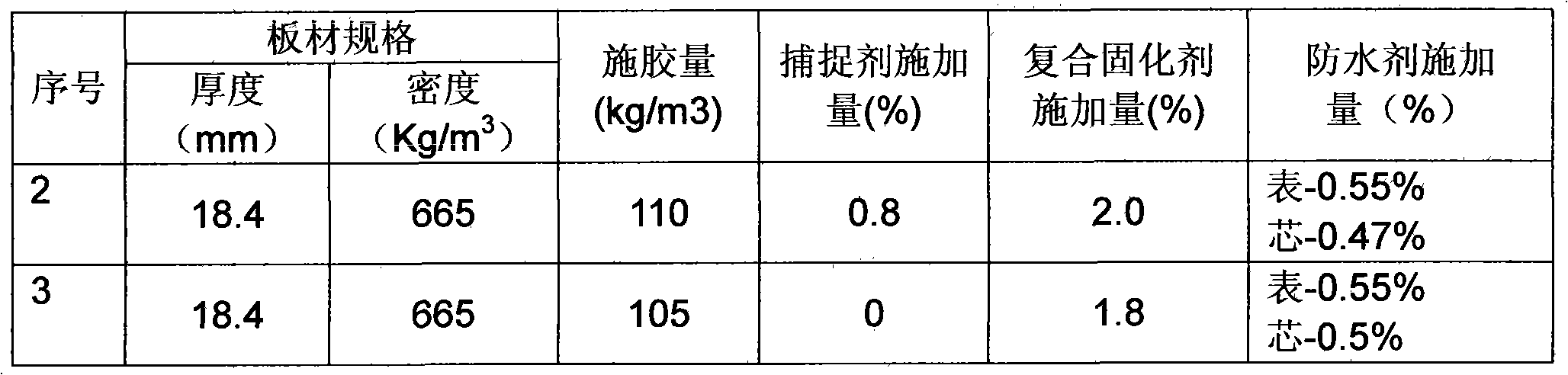

Embodiment 2~3

[0052] Examples 2-3 respectively adopt the method of the present invention to manufacture E0 or E1 grade particleboard boards. The process steps adopted are the same as in Example 1, and the synthetic resin used, composite curing agent, formaldehyde trapping agent and waterproofing agent are all the same as Example 1, the difference is that the specific conditions are different in the sizing process, and the parameters such as sizing are shown in Table 5, the properties of the prepared plates are shown in Table 6:

[0053] table 5

[0054]

[0055] Table 6

[0056]

[0057] Note: The water absorption thickness expansion rate in the table is 2 hours

Embodiment 4~5

[0059] Examples 4 to 5 respectively adopt the method of the present invention to manufacture E0 or E1 level moisture-proof particleboard boards with low water absorption thickness expansion ratio. The process step adopted is the same as Example 1, and the synthetic resin used, composite curing agent, formaldehyde scavenger and waterproofing agent are all the same as Example 1, and the difference lies in the difference in the specific conditions in the sizing process, waterproofing agent, sizing amount Other parameters are shown in Table 7, and the properties of the prepared plates are shown in Table 8:

[0060] Table 7

[0061]

[0062] Table 8

[0063]

[0064] Note: TS in the table is the 24-hour water absorption thickness expansion rate

[0065] Compared with ordinary particleboard, this embodiment has high structural performance, and various physical and chemical properties have reached and exceeded the relevant national standards. The excellent low water absorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com