Full-automatic accurate garlic transplanter and planting method

A fully automatic, planting machine technology, applied in planting methods, potato planters, planter parts, etc., can solve the problems of inability to locate garlic cloves, difficult to locate and plant operations, difficult to apply to the garlic planting industry, etc., to achieve simple and practical. The effect of price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

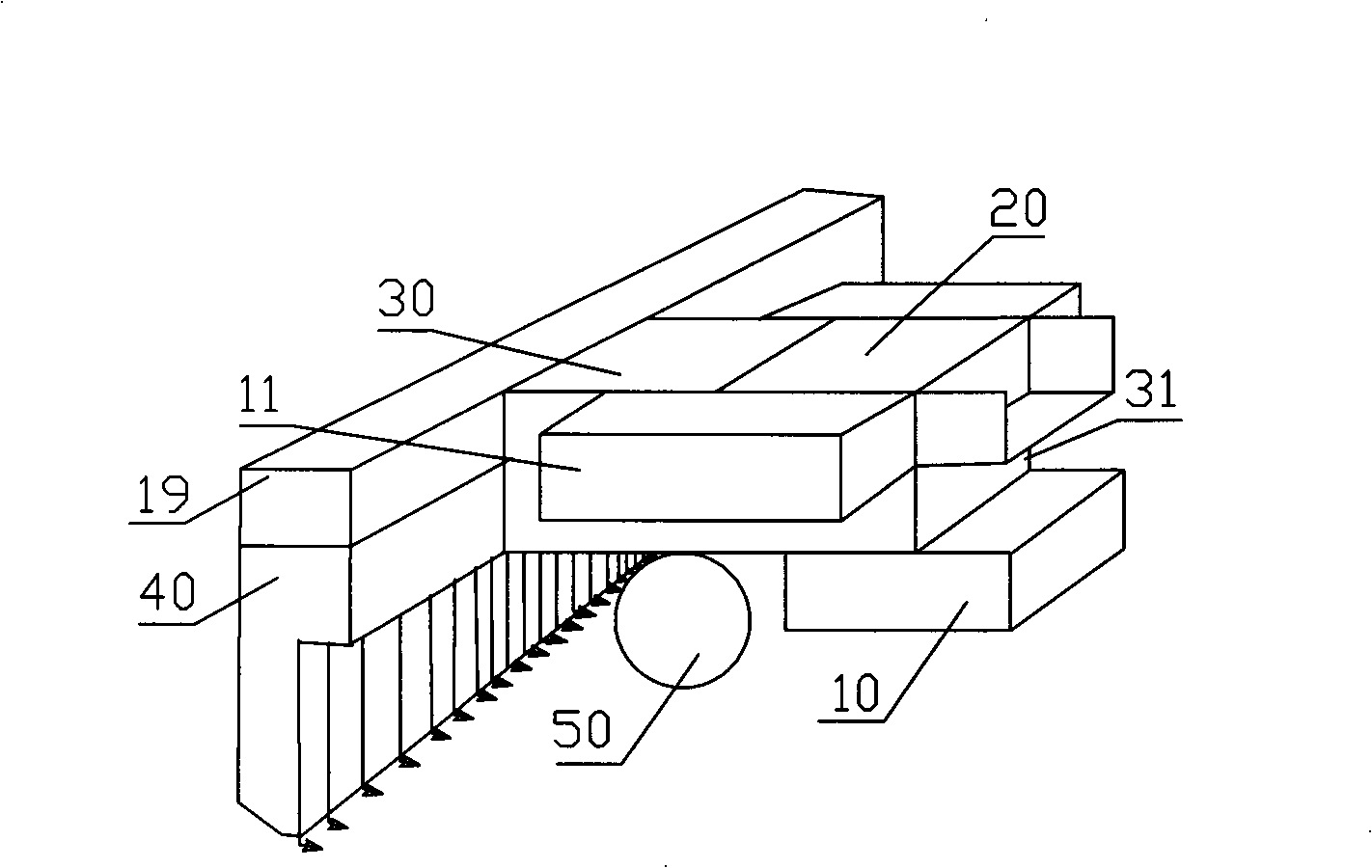

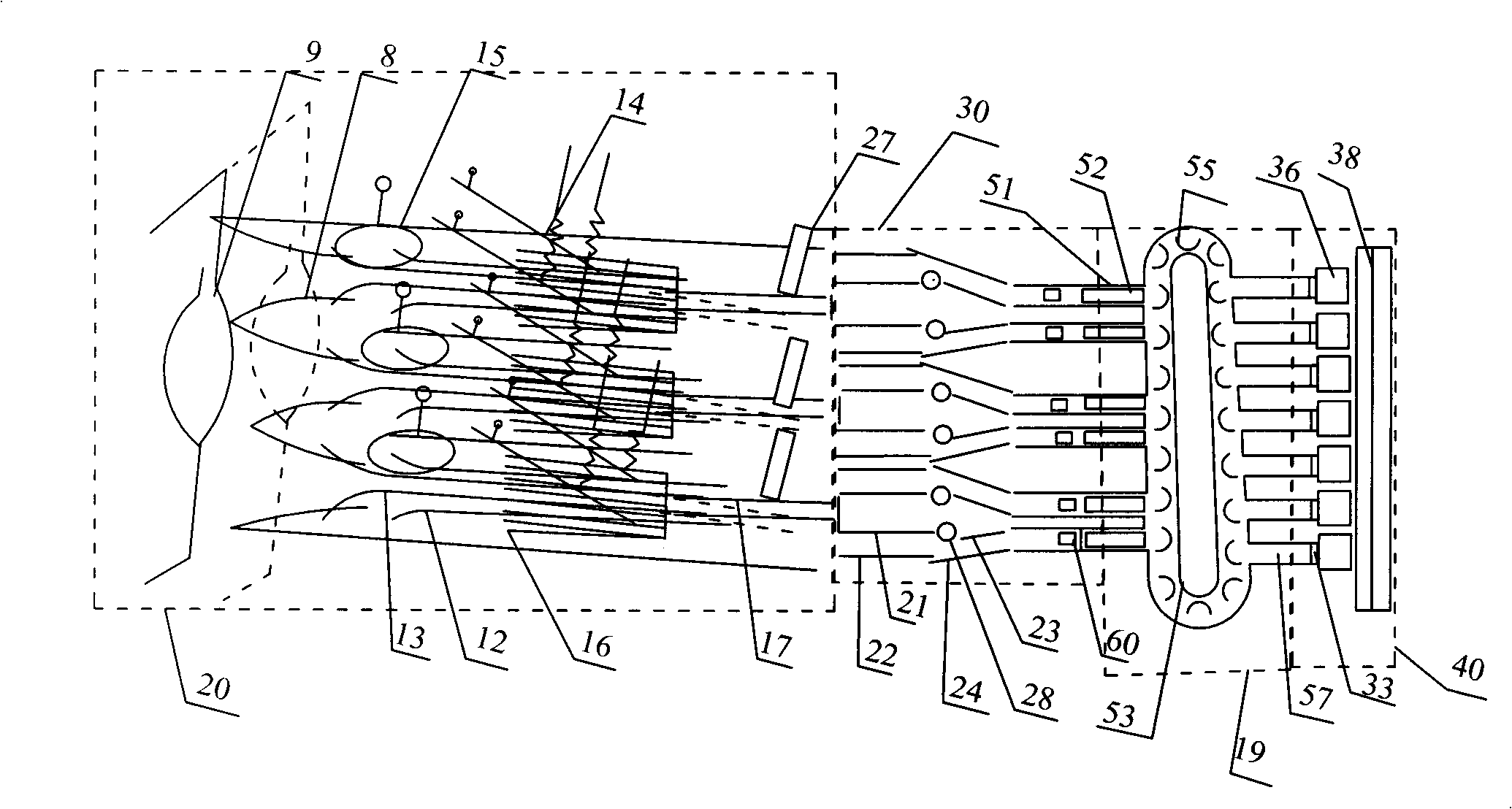

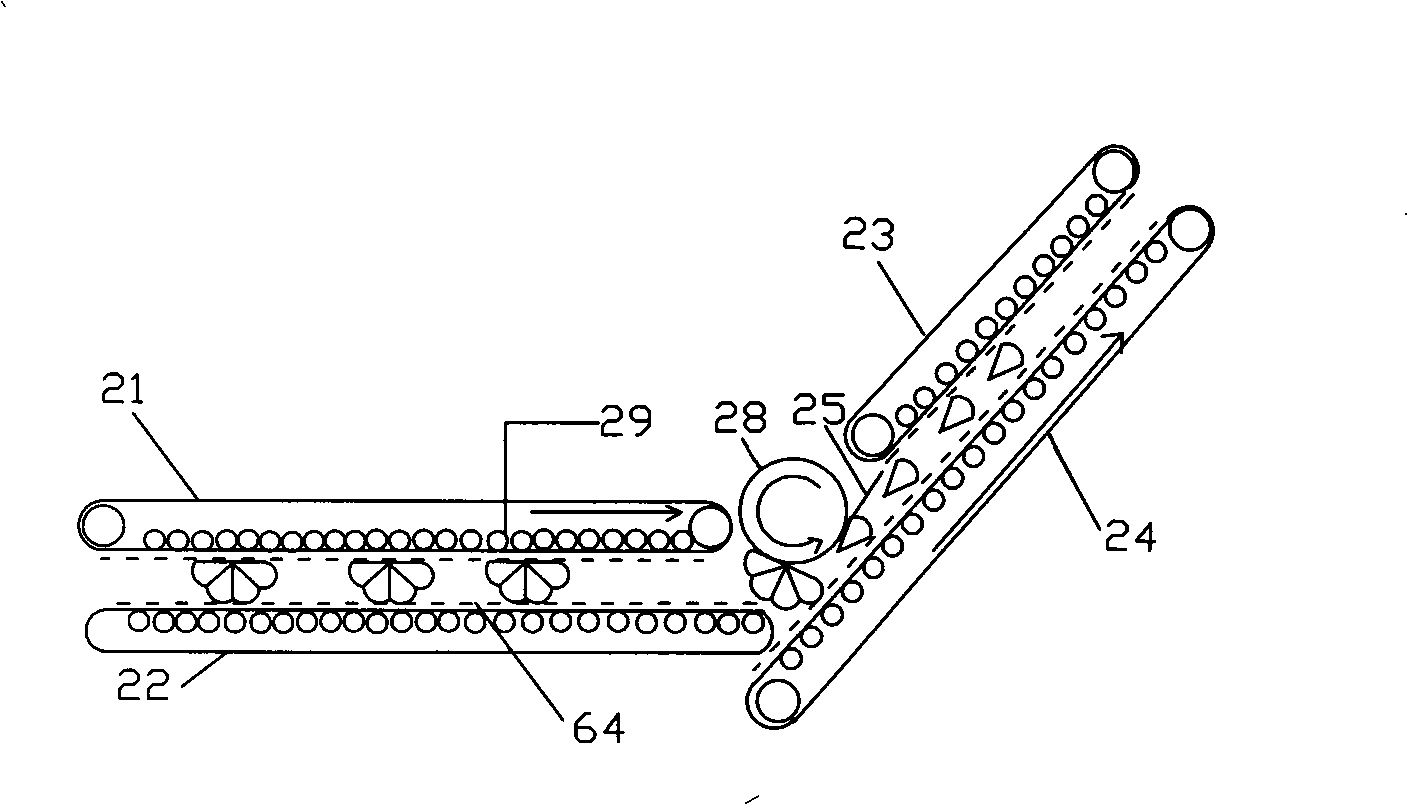

[0054] Such as figure 1 As shown, a fully automatic precision garlic planting machine includes a frame 31, a gearbox 10 is arranged on the frame 31, a running mechanism 50, that is, a wheel is arranged at the lower end of the frame 31, and the sequentially connected wheels arranged on the frame 31 are also included. Feeding mechanism 20, garlic clove peeling mechanism 30, batching mechanism 19 and insertion, hole tracking detection and replanting mechanism 40;

[0055] The front end on the frame 31 is provided with a feeding mechanism 20, the output end of the feeding mechanism 20 is connected with a garlic clove peeling mechanism 30, and the output end of the garlic clove peeling mechanism 30 is connected with a batching mechanism 19, and at the output end of the batching mechanism 19 Connect with interplanting, hole tracking detection and replanting mechanism 40, be provided with gearbox 10 below feeding mechanism 20 and link to frame 31, be provided with traveling mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com