Liner type concrete tank molding device

A molding device and concrete technology, applied in packaging, building types, large containers, etc., can solve the problems of high technical requirements for digestion tank construction, unfavorable large-scale rapid promotion, high cost, etc., achieve excellent mechanical properties, speed up promotion, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

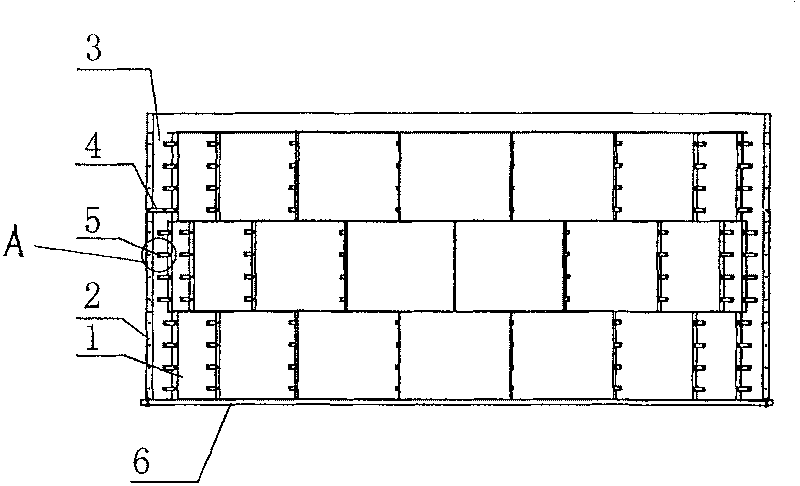

[0036] Example: from figure 1 It can be clearly seen that the liner-lined concrete tank body forming device is composed of a fiberglass inner tank 1 and a steel outer mold 2.

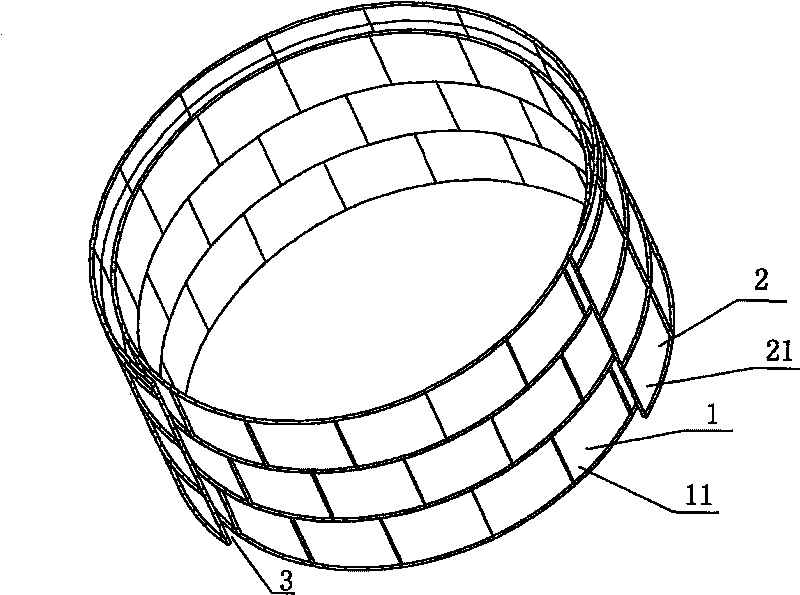

[0037] like figure 2 As shown, the inner tank 1 is cylindrical and is assembled by connecting a plurality of lining plates 11 through bolts and nuts. The outer mold 2 is cylindrical and is assembled by a plurality of templates 21 connected by bolts and nuts. The outer mold 2 and the inner container 1 form a concrete casting cavity 3 .

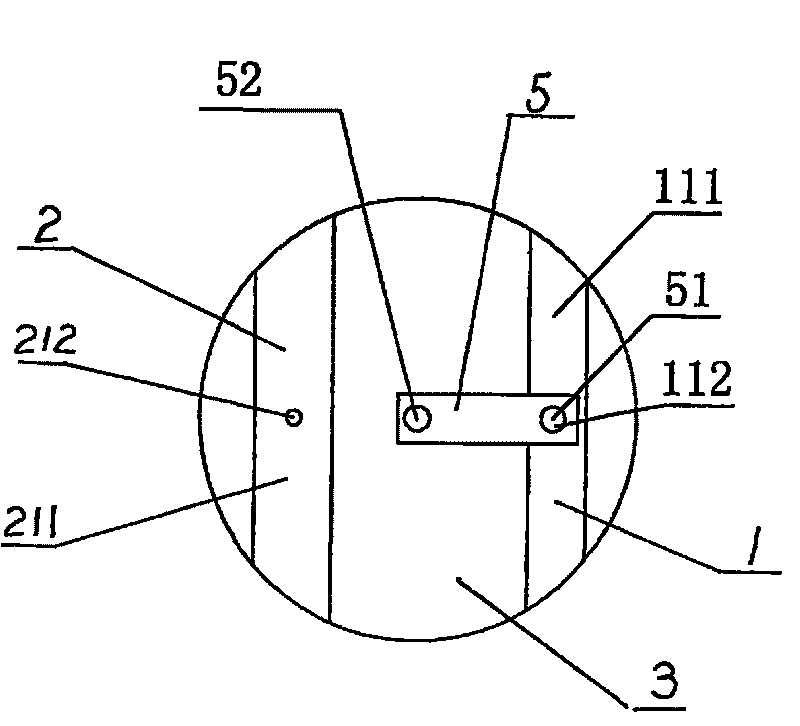

[0038] from image 3 It can be clearly seen that the periphery of the template 21 is provided with a template flange 211 with a second connecting hole 212, and the two templates 21 can be connected by bolts and nuts through the template flange 211 to form an outer mold. The periphery of the liner 11 is provided with a liner fold 111 with a first connection hole 112, and the two liner 11 can be connected by bolts and nuts through the liner fold 111 to form an inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com