Hydrocracking catalyst and preparation thereof

A hydrocracking and catalyst technology, applied in the fields of hydrocarbon oil cracking, petroleum industry, etc., can solve the problems that the selectivity of medium oil has not been significantly improved, the catalyst activity has not been significantly improved, and the catalyst reactivity is poor, and the BMCI value has been reduced. , activity improvement, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

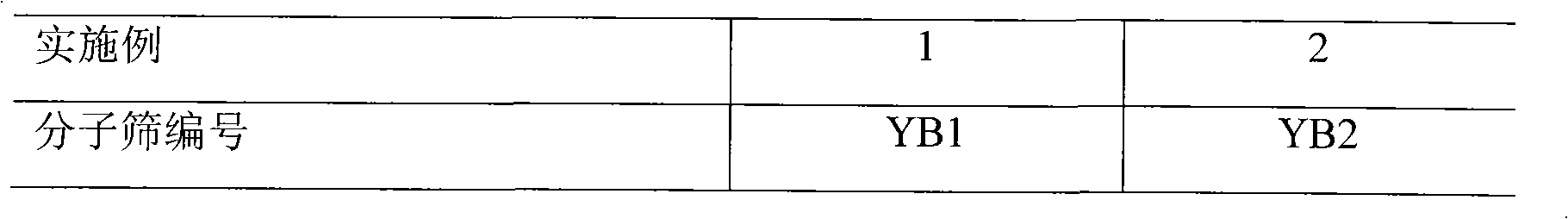

Embodiment 1

[0050] The Y / β double microporous molecular sieve is synthesized by the double microporous composite molecular sieve synthesis method disclosed in Chinese patent CN1583562A, and the specific steps are carried out according to Example 2 in the patent. The obtained Y / β double microporous composite molecular sieve is coded as YB1. Put 100g of YB1 raw powder into the closed treatment furnace, and pass it into SiF at a flow rate of 15ml / min 4 SiF at a concentration of 20mmol / L 4 Mix gas with nitrogen, and raise the temperature of the treatment furnace to 200°C for 2h at a heating rate of 5°C / min. After the process is completed, the mixed gas is stopped, and the temperature is lowered to room temperature for hydrothermal treatment. The specific conditions are to increase the temperature to 550°C at a heating rate of 2.0°C / min and keep the pressure at 0.1MPa, release the pressure after 2 hours of treatment, and drop the temperature to room temperature. Dilute the washed double mic...

Embodiment 2

[0052] The Y / β double microporous composite molecular sieve is synthesized by the synthesis method of the double microporous composite molecular sieve disclosed in Chinese patent CN1583563, and the specific steps are carried out according to Embodiment 4 in the patent. The obtained Y / β double microporous composite molecular sieve is coded as YB2. Put 100g of YB2 raw powder into the airtight treatment furnace, and feed SiCl at a flow rate of 20ml / min 4 SiCl with a concentration of 50mmol / L 4 Mix gas with nitrogen, and raise the temperature of the treatment furnace to 150°C for 4 hours at a heating rate of 8°C / min. After the process is completed, stop feeding the mixed gas for hydrothermal treatment. The specific conditions are to increase the temperature to 575°C at a heating rate of 10.0°C / min, and maintain a pressure of 0.3MPa, release the pressure after 2 hours of treatment, and drop the temperature to room temperature. Dilute the washed double microporous molecular sieve...

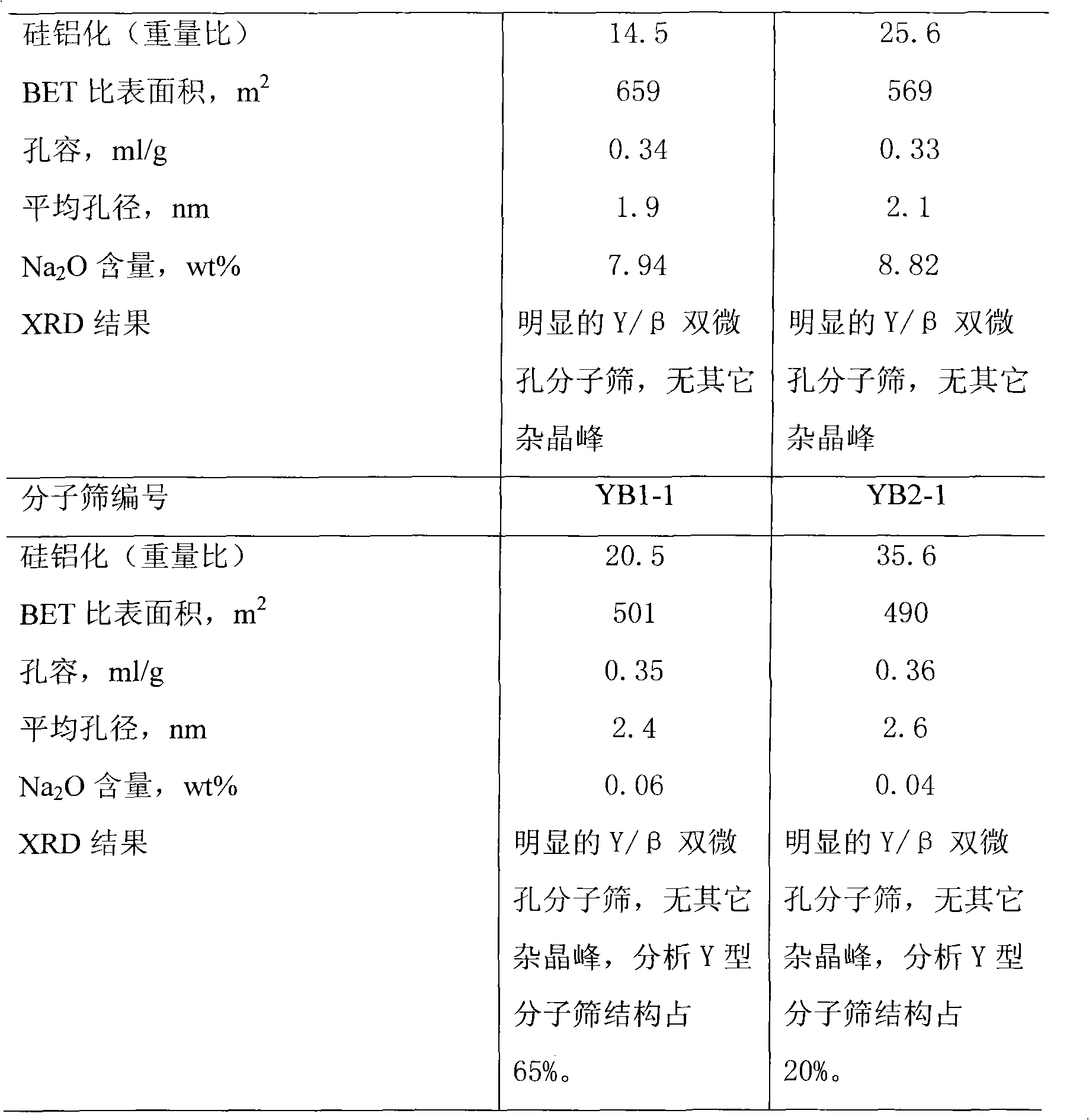

Embodiment 3

[0058] USY molecular sieve is produced by Wenzhou Huahua Group Company, the number is USY1. The molecular sieve was treated at a treatment temperature of 500° C. and a water vapor pressure of 0.10 MPa for 2.0 hours, then the pressure was released, and the temperature dropped to room temperature. The number is USY1-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com