Novel polysulfide rubber and preparation thereof

A technology of polysulfide rubber and formulation, applied in the field of polysulfide rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1. Novel polysulfide rubber and preparation method thereof

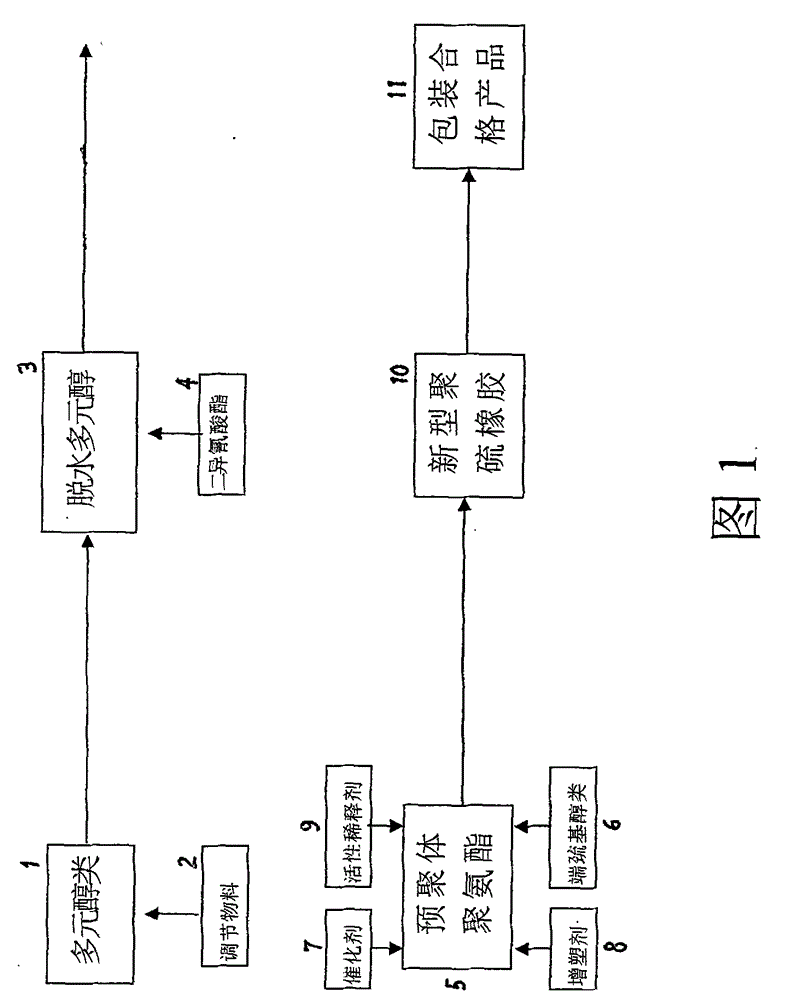

[0030] The technical scheme of the novel polysulfide rubber and the preparation method thereof of the present embodiment comprises two parts: one is the technical scheme about the novel polysulfide rubber; the other is the technical scheme about the preparation method of the novel polysulfide rubber.

[0031] 1. New polysulfide rubber

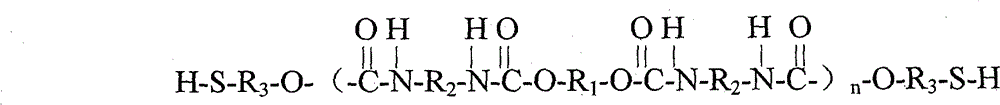

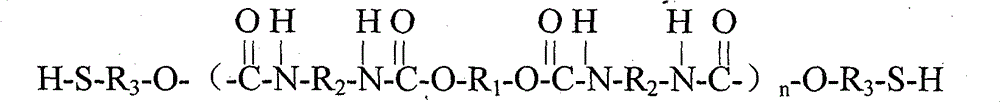

[0032] The new polysulfide rubber of this example adopts special grafting technology to graft the terminal mercapto group to the end of the polyurethane macromolecular chain, and after sealing the end, a new type of polysulfide rubber is made. The polysulfide rubber of this example is a high polysulfide rubber with the following structural formula Molecular compound:

[0033]

[0034] In the structural formula: n is selected as: n==3. R 1 The structural formula is: HO-R-OH, where the structural formula of R is an ether or ester compound containing two or three ...

Embodiment 2

[0039] Embodiment two. Novel polysulfide rubber and preparation method thereof

[0040] The technical proposal of the novel polysulfide rubber and its preparation method in this embodiment includes two parts: one is the technical proposal about the novel polysulfide rubber; the other is the technical proposal about the preparation method of the novel polysulfide rubber.

[0041] 1. New polysulfide rubber

[0042] The difference between the novel polysulfide rubber of this example and that described in Example 1.1 is: a. n is selected as: n=2 in the polymer compound structural formula of the polysulfide rubber of this example. R 1 The R structural formula in the selection is polyether polyol series, such as polyether polyol series: N305, N310, N320, N330, etc., you can choose any one of them, such as each of them; or choose any two of them Types, such as N305 and N310, N320 and N330, etc.; or choose any three, such as choosing the first three or the last three; or choose to u...

Embodiment 3

[0045] Embodiment three. Novel polysulfide rubber and preparation method thereof

[0046] The technical proposal of the novel polysulfide rubber and its preparation method in this embodiment includes two parts: one is the technical proposal about the novel polysulfide rubber; the other is the technical proposal about the preparation method of the novel polysulfide rubber.

[0047] 1. New polysulfide rubber

[0048] The difference between the novel polysulfide rubber of this example and embodiment one.1., embodiment two.1. has: a. n is selected as: n==1 in the macromolecular compound structural formula of this example polysulfide rubber . R 1 The R structural formula in is selected as an ester compound containing two or three hydroxyl groups: castor oil, hydrogenated castor oil, or both. R 2 The R' structural formula in is selected from alicyclic diisocyanate: IPDI, HTDI, HMDI, HLDI, etc., select any one of them, such as each of them; or select any two of them, as listed T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com