Novel polysulfide rubber and preparation method thereof

A polysulfide rubber, a new type of technology, applied in the field of polysulfide rubber, can solve problems such as intolerance to storage, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

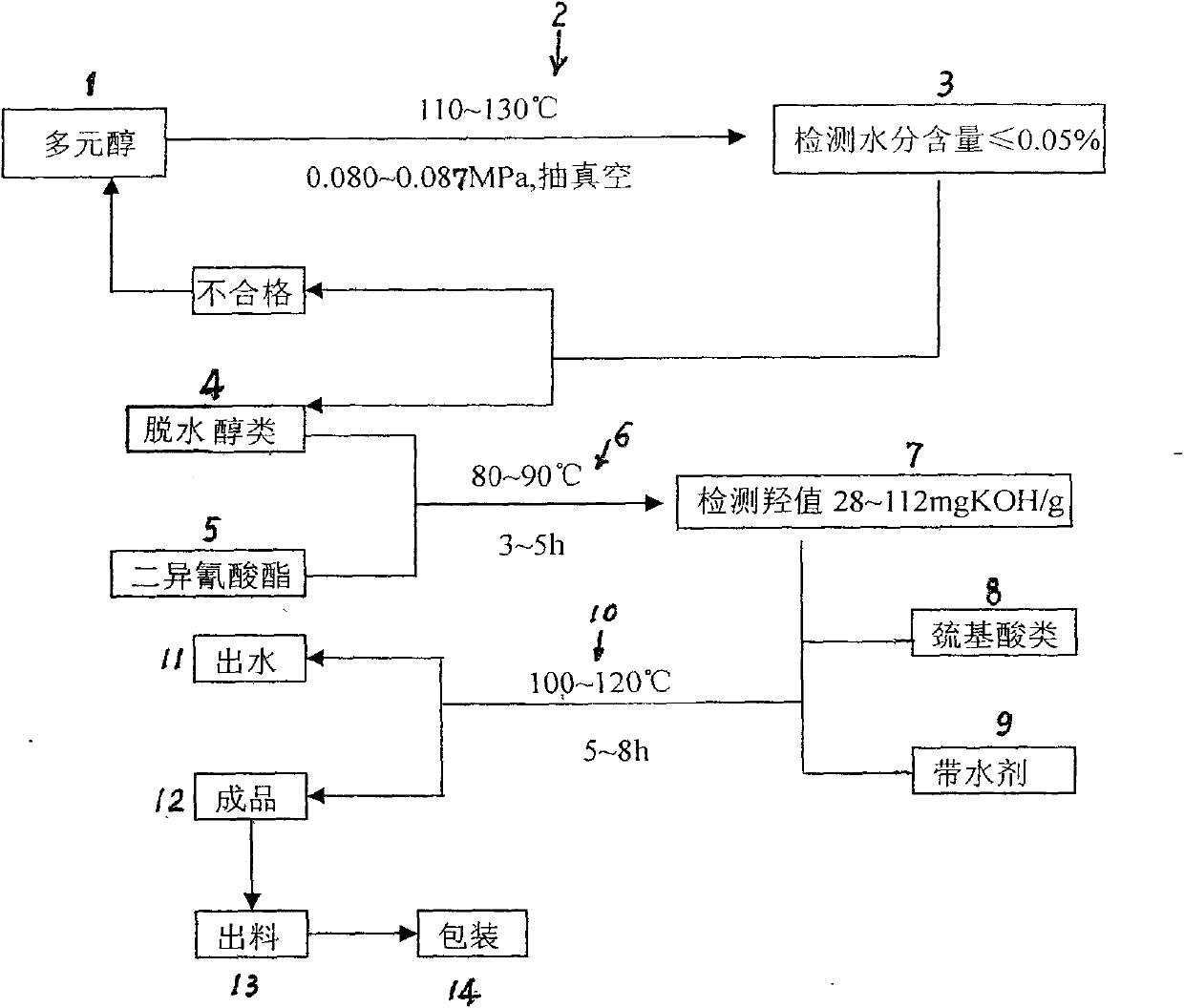

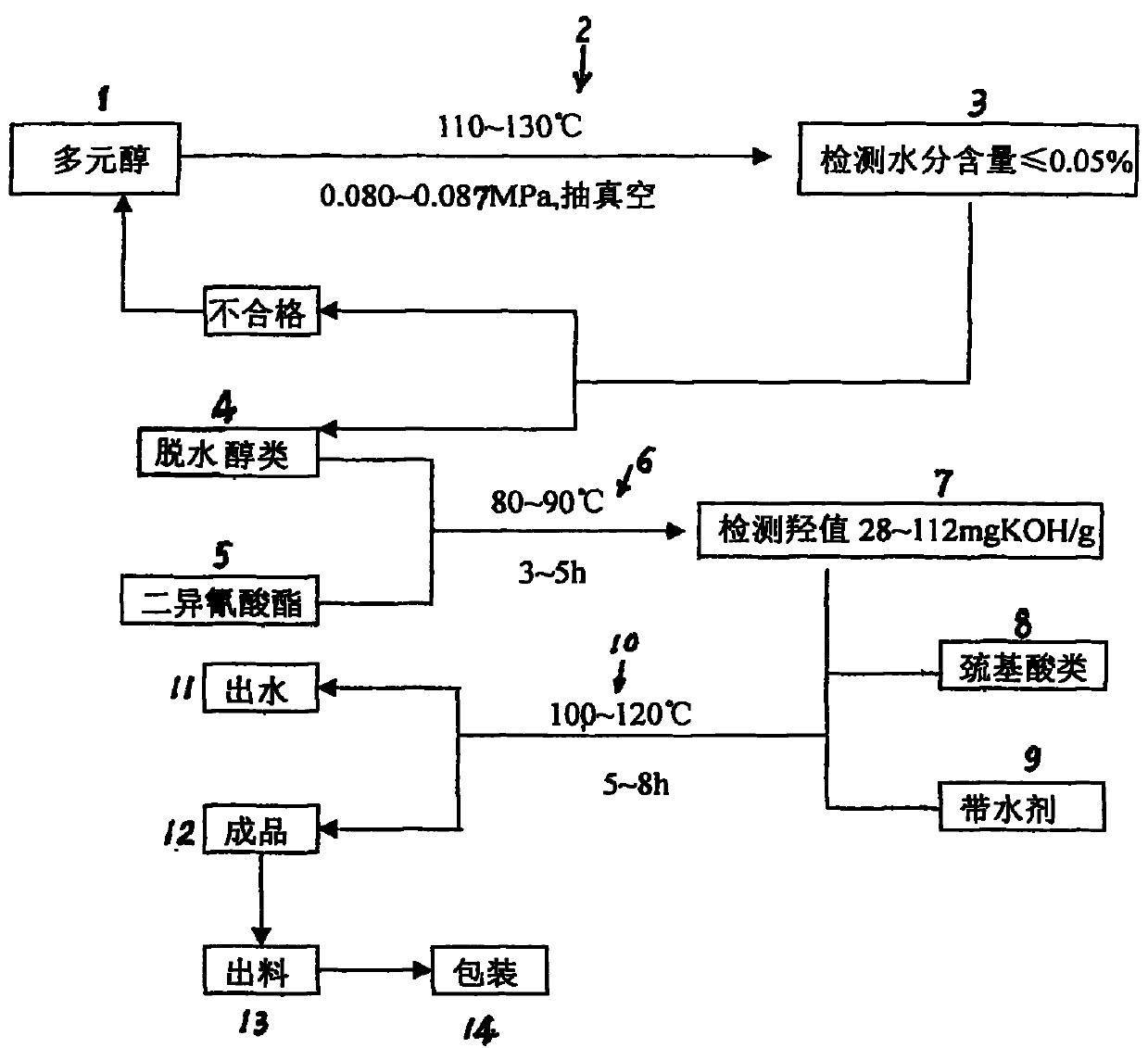

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1. Novel polysulfide rubber has ten small examples

example 1

[0026] Example 1. New polysulfide rubber

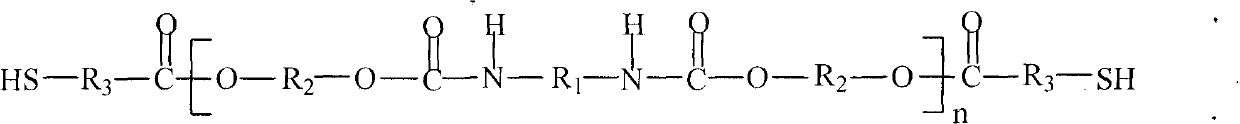

[0027] The new polysulfide rubber of this example adopts special grafting technology to graft the terminal mercapto group to the end of the polyurethane macromolecular chain, and after capping, a new type of polysulfide rubber is made. The polysulfide rubber in this example is a macromolecule with the following structural formula Compound:

[0028]

[0029] In the structural formula: this example n is selected as: n=1, R 1 Selected from structural formula O=C=N-R 1 -N=C=O, where R 1 is a diisocyanate, the R 1 Choose any one, or any two, or any three of the diisocyanates: if you choose aromatic TDI a diisocyanate, or if you choose aliphatic HDI, TMHDI two diisocyanates, or if you choose alicyclic IPDI, HTDI, HMDI three kinds of diisocyanate etc. of family, but the diisocyanate formula and component weight ratio of this example are 80 parts by weight. R 2 Selected from structural formula HO-R 2 -OH, where R 2 is a polyol, the...

example 2

[0030] Example 2. New polysulfide rubber

[0031] The new polysulfide rubber of this example adopts special grafting technology to graft the terminal mercapto group to the end of the polyurethane macromolecular chain, and after capping, a new type of polysulfide rubber is made. The polysulfide rubber in this example is a macromolecule with the following structural formula Compound:

[0032]

[0033] In the structural formula: this example n is selected as: n=2, R 1 Selected from structural formula O=C=N-R 1 -N=C=O, where R 1 is a diisocyanate, the R 1 Choose any one, or any two, or any three of the diisocyanates: if you choose aliphatic LDI a diisocyanate, or if you choose alicyclic IPDI, HLDI two diisocyanates, or if you choose aromatic The TDI, MDI, PPDI three kinds of diisocyanate etc. of family, but the diisocyanate formula and component weight ratio of this example are 82 parts by weight. R 2 Selected from structural formula HO-R 2 -OH, where R 2 is a polyol, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com