Hoisting mechanism of crane for coke pot

A lifting mechanism and crane technology, which is applied in the field of lifting transportation and coking machinery, can solve problems such as horizontal center of gravity deviation, unfavorable maintenance, large drum structure, etc., achieve uniform force, novel structure, and meet operating requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

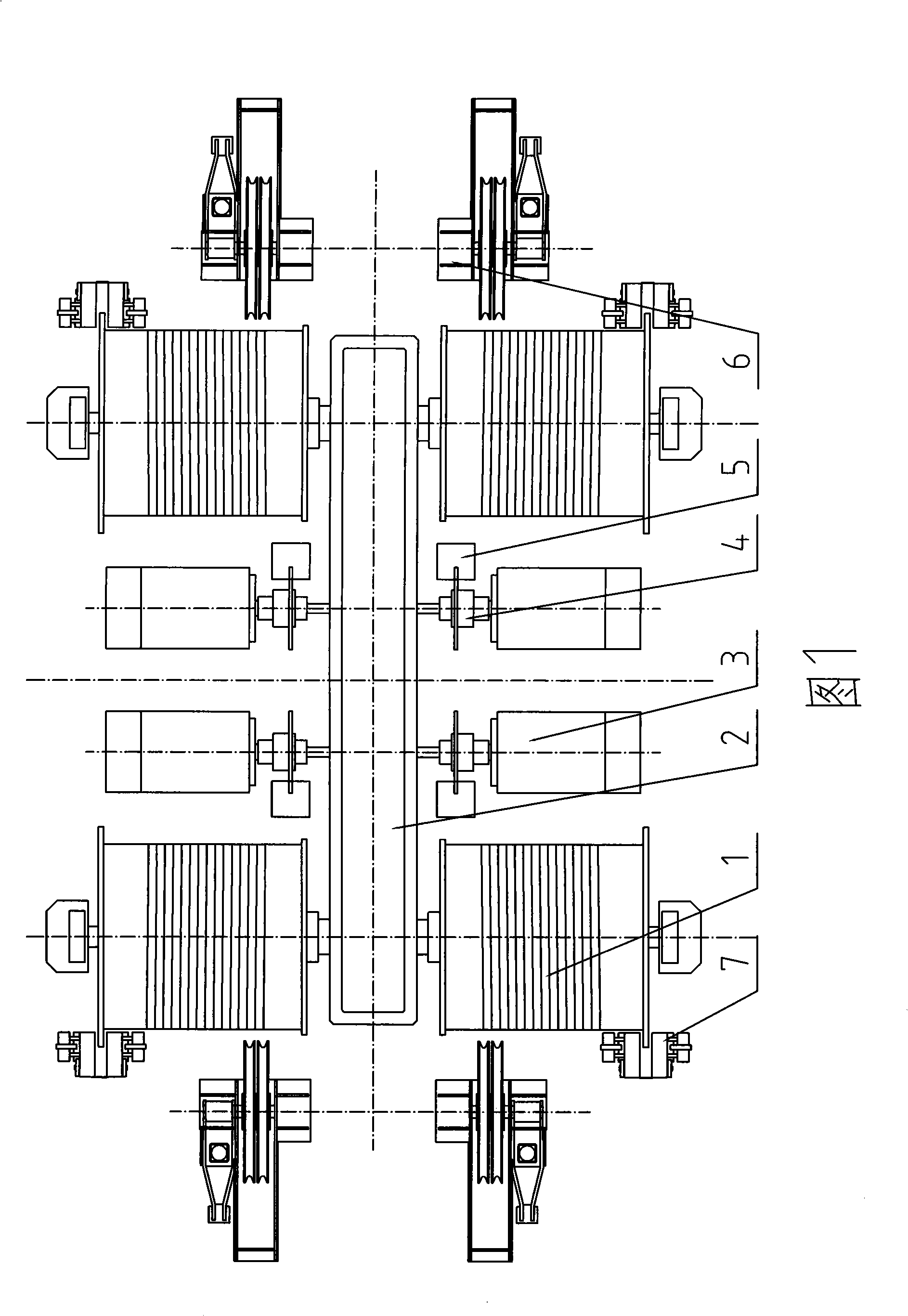

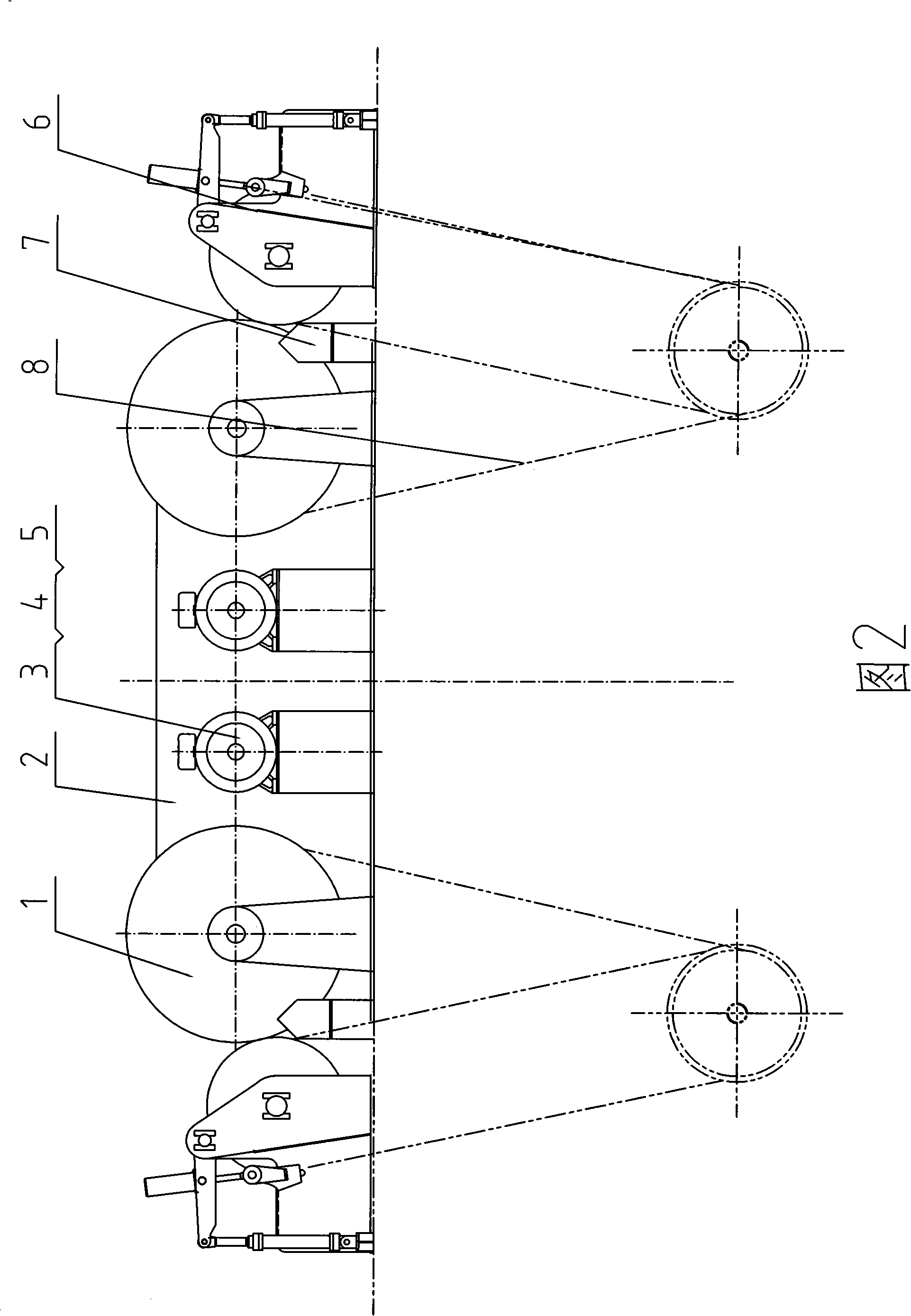

[0014] The specific embodiment of the present invention is shown in accompanying drawing, is made up of reel set 1, planetary reducer 2, motor 3, fixed pulley block 6, shaft coupling 4, brake 5, fixed pulley block 6, safety brake 7. Its structure is that the planetary reducer 2 installed on the lifting trolley has four input shaft ends and four output shaft ends arranged symmetrically. The four input shafts are arranged in the middle of the planetary reducer, and are respectively connected with four motors 3 through couplings 4, and brakes 5 are respectively installed on the couplings 4. The four output shafts are arranged on both sides of the end of the planetary reducer, respectively connected to the four single-connected reel sets 1, and the safety brake 7 directly acts on the edge of the reel of the single-connected reel set. The fixed pulley block 6 is installed on the opposite side of the single-connected reel block, and is connected by a wire rope system 8. The four ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com