Separated splint conveying apparatus for bamboo splints

A conveying device and technology of bamboo chips, which are applied in the directions of transportation and packaging, pile separation, and object separation, etc., can solve the problem of not being able to transport thin bamboo chips one by one, so as to get rid of the dependence of workers' craftsmanship, maintain a stable and balanced posture, and prevent adhesion. strip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

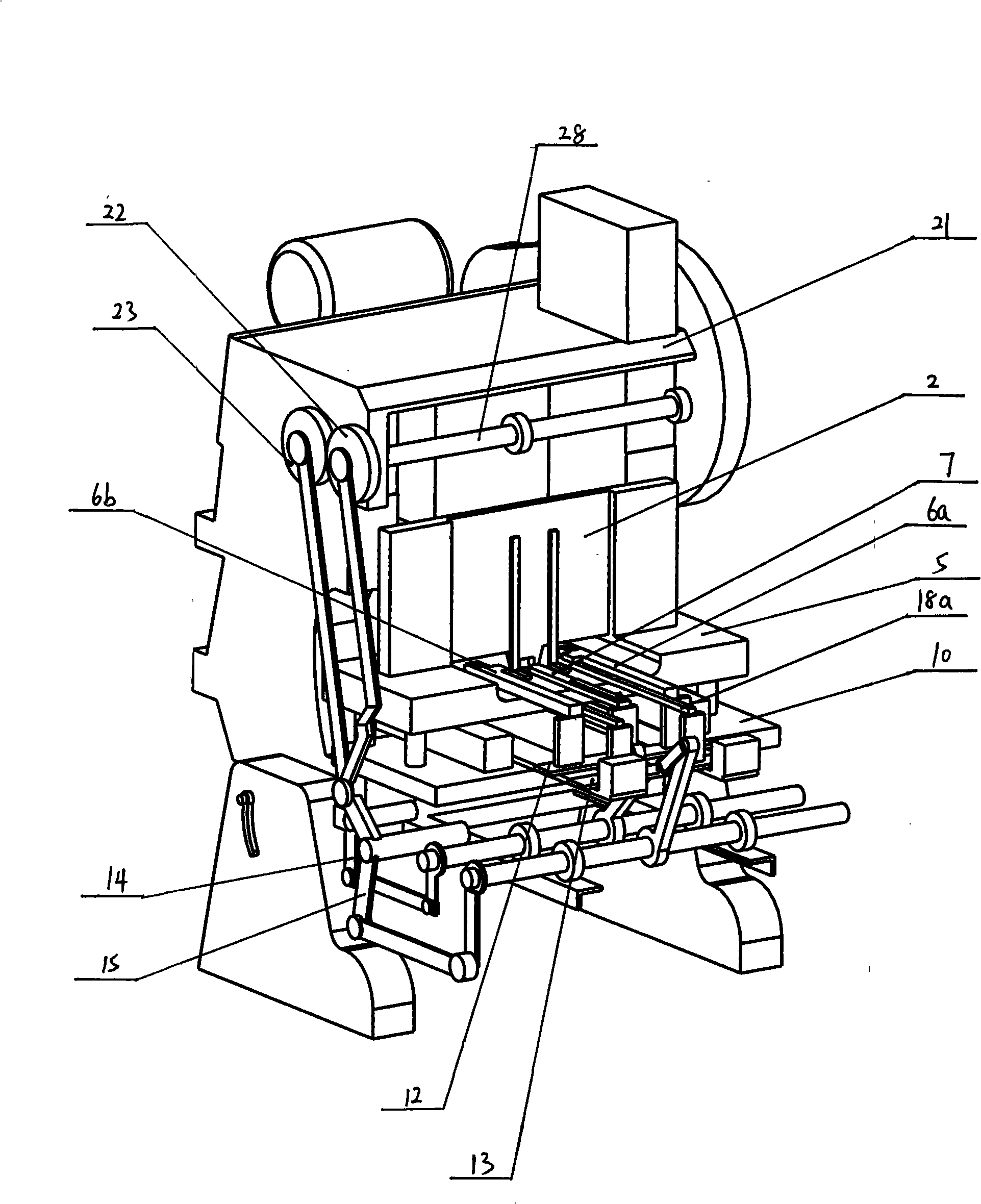

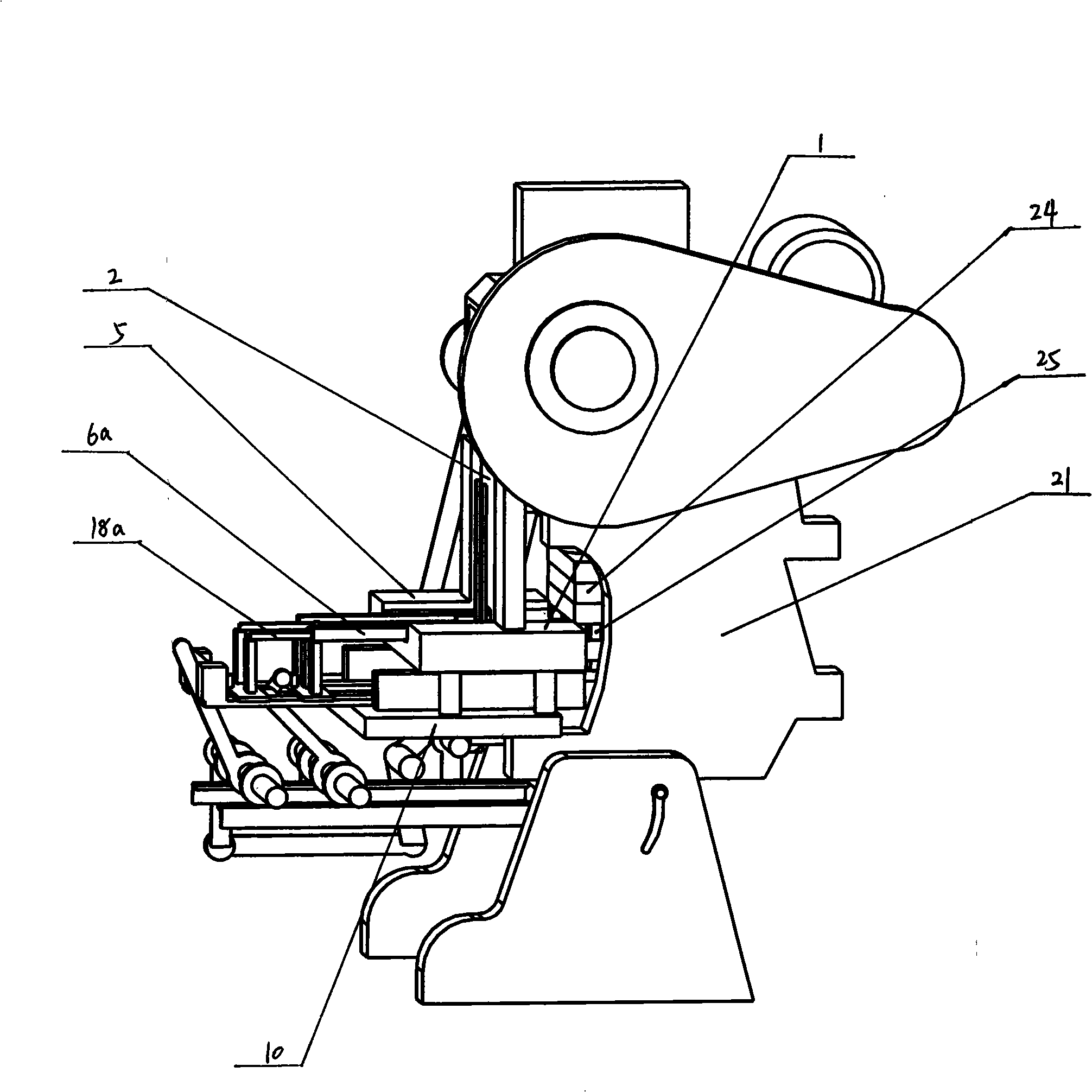

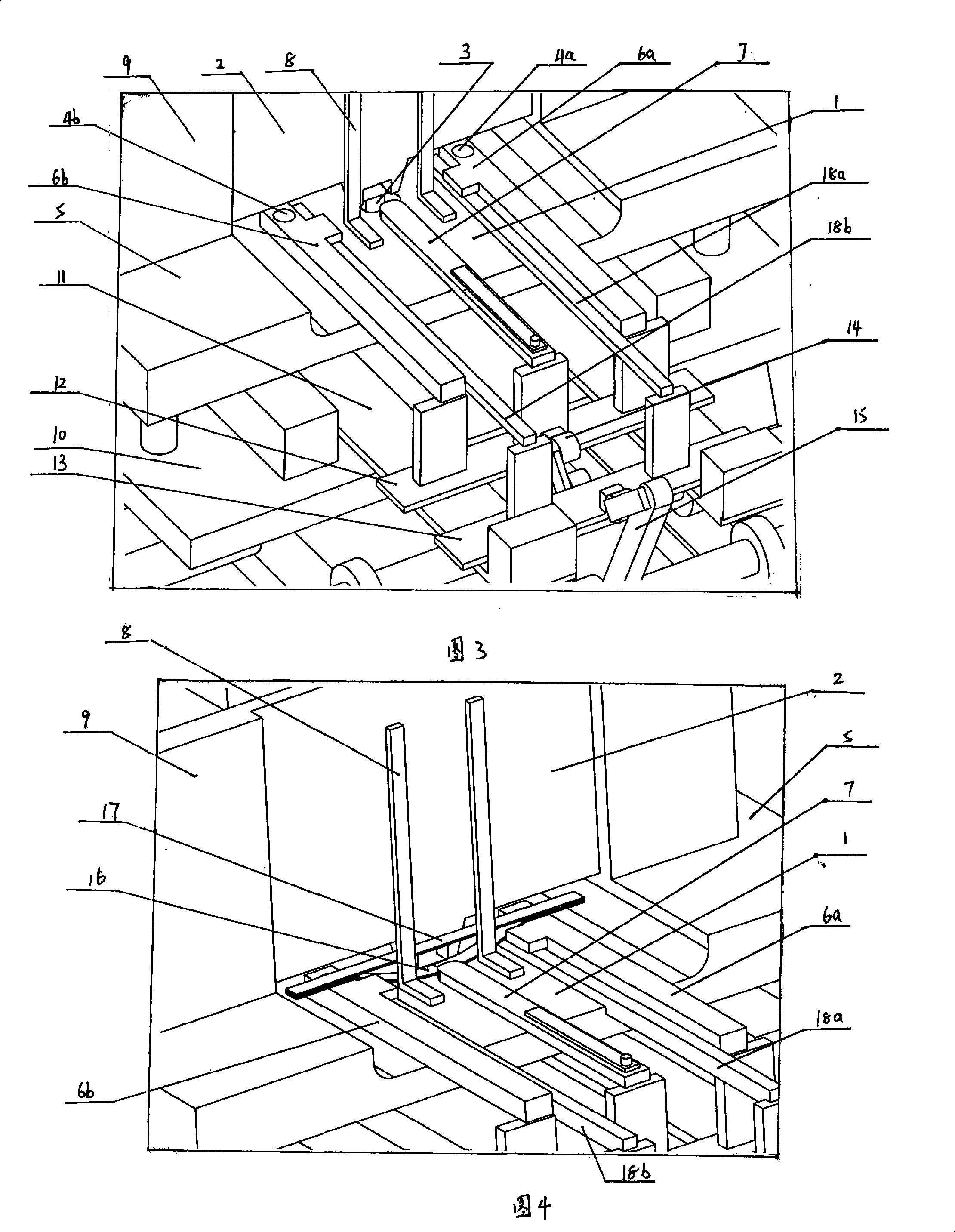

[0031] Referring to the attached picture:

[0032] The bamboo slice conveying device according to the present invention comprises a frame 10, a base plate 5 provided with a bamboo slice conveying channel 1, and the bamboo slice conveying channel 1 is connected to a stamping station on a stamping machine 21. A female mold 25 and a positive mold 24 for making fan ribs are housed on the stamping station.

[0033] A storage tank 2 for stacking bamboo chips is arranged above the bamboo chip conveying channel 1 , and the opening at the bottom of the storage tank 2 is adapted to the bamboo chip and aligned with the bamboo chip conveying channel 1 . The opening at the bottom of the storage tank 2 is arranged transversely with respect to the bamboo chip conveying channel 1 , that is, the long side of the opening is perpendicular to the bamboo chip conveying channel 1 . Storage tank 2 of the present embodiment is made of vertical board 9 and front retaining strip 8, and groove is arran...

Embodiment 2

[0049] The special added measures of this embodiment are: the bottom of the front end of the middle fork 7 has a notch 27 for inserting the bamboo slice, and the height of the notch 27 is suitable for the bamboo slice.

[0050] Can make middle fork 7 like this when pushing away bamboo slice 16, suppress bamboo slice 16, prevent it from jumping, rocking.

[0051] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com