Upgrading mould apparatus with tapping

A mold and progressive technology, applied in tangent devices, manufacturing tools, forming tools, etc., can solve the problems of environmental sanitation, low production efficiency, and difficulty in ensuring the strength of cutting threads. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

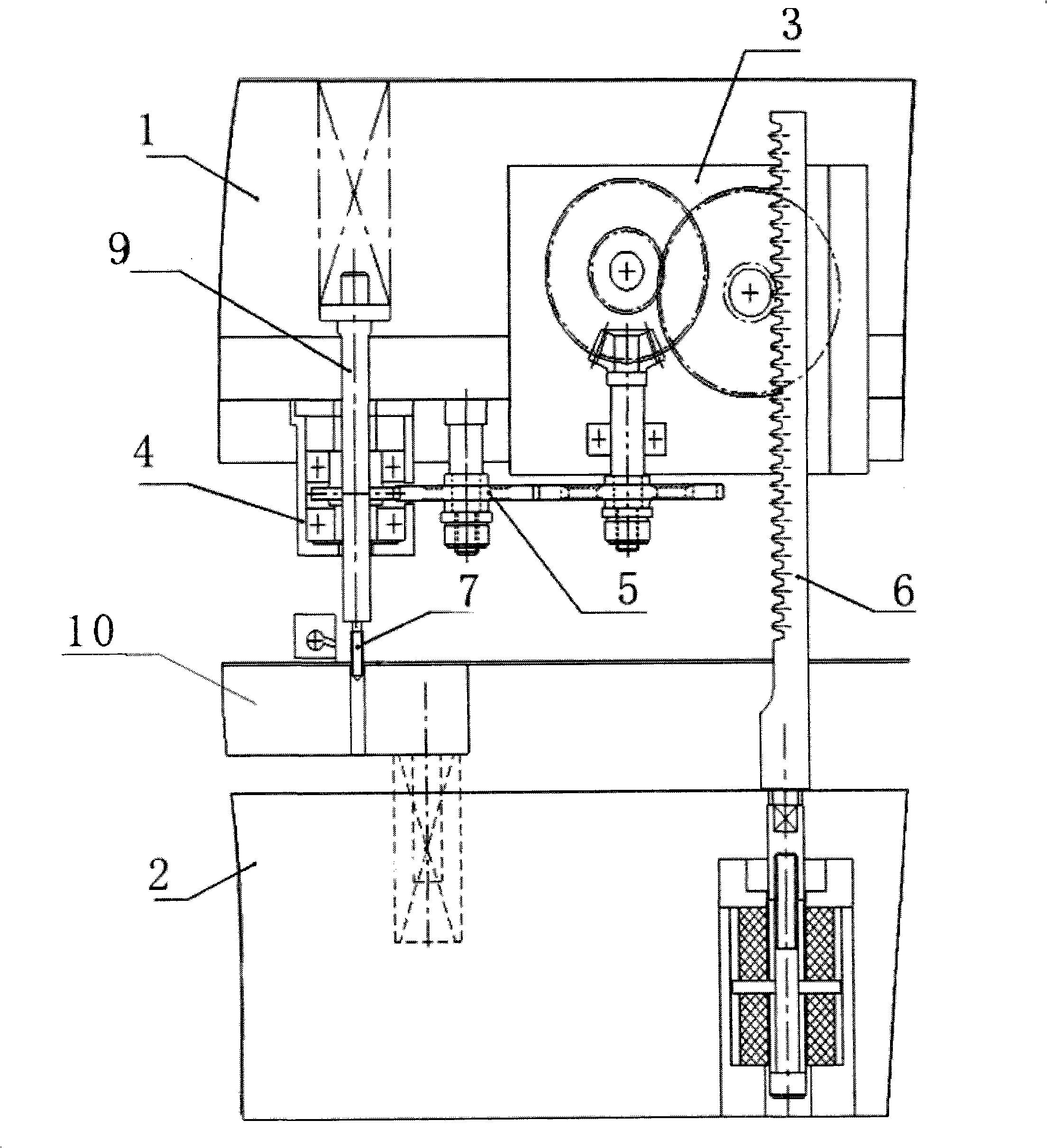

[0010] The present invention is implemented according to the above-mentioned technical scheme. The strip material to be tapped is a metal strip material, generally small hole tapping, and the rack is fixed on the lower mold of the mold by the rack holder, and two pieces of polyurethane are used in the rack holder. The rack is clamped by grease rubber, which can play a good role in shock absorption and protection.

[0011] The present invention can add a plurality of transmission gears and transmission boxes, so that tapping can be performed on multiple positions at the same time.

[0012] The invention completes tapping simultaneously in the stamping process, which organically integrates traditional stamping and tapping technologies, effectively changes the traditional production method of "stamping first and then tapping", and greatly improves production efficiency. The production cost is reduced and the economic benefit is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com