Refrigerant compressor

A refrigerant and compressor housing technology, applied in household refrigeration devices, mechanical equipment, machines/engines, etc., can solve the problems of non-exclusion, susceptible to corrosion, warping of collection containers, etc., to ensure accurate fit, adaptation, corrosion, etc. Simple problem, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

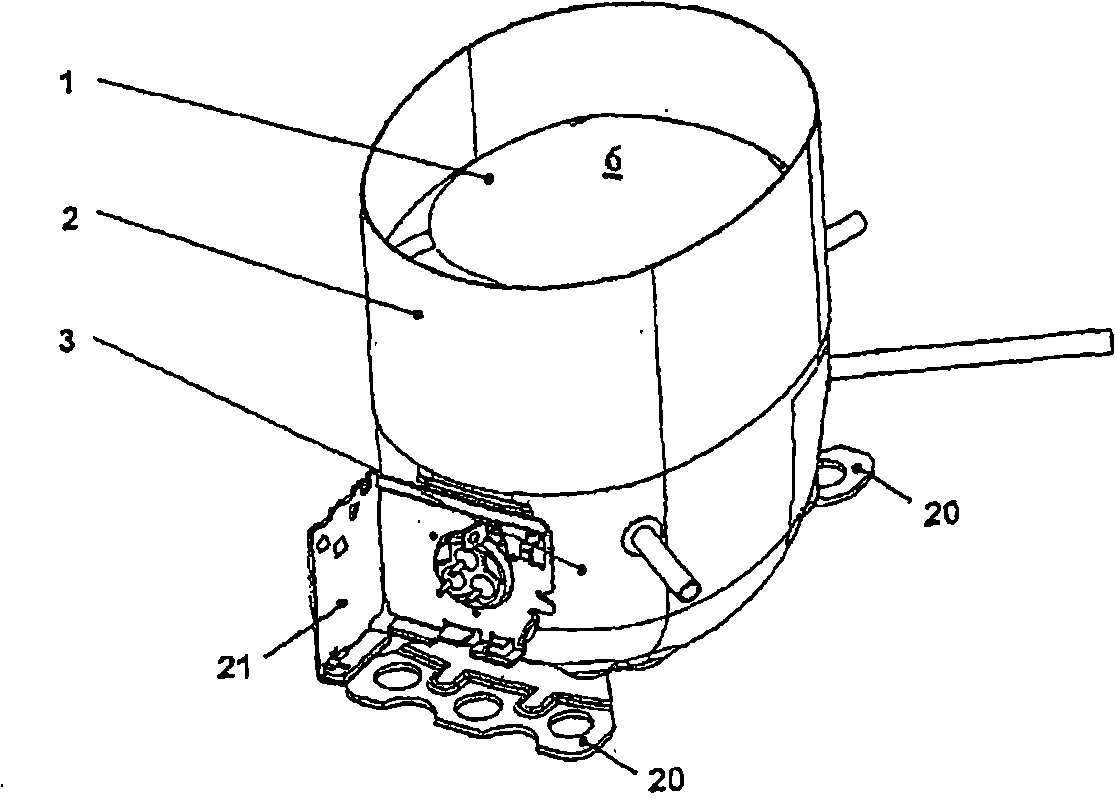

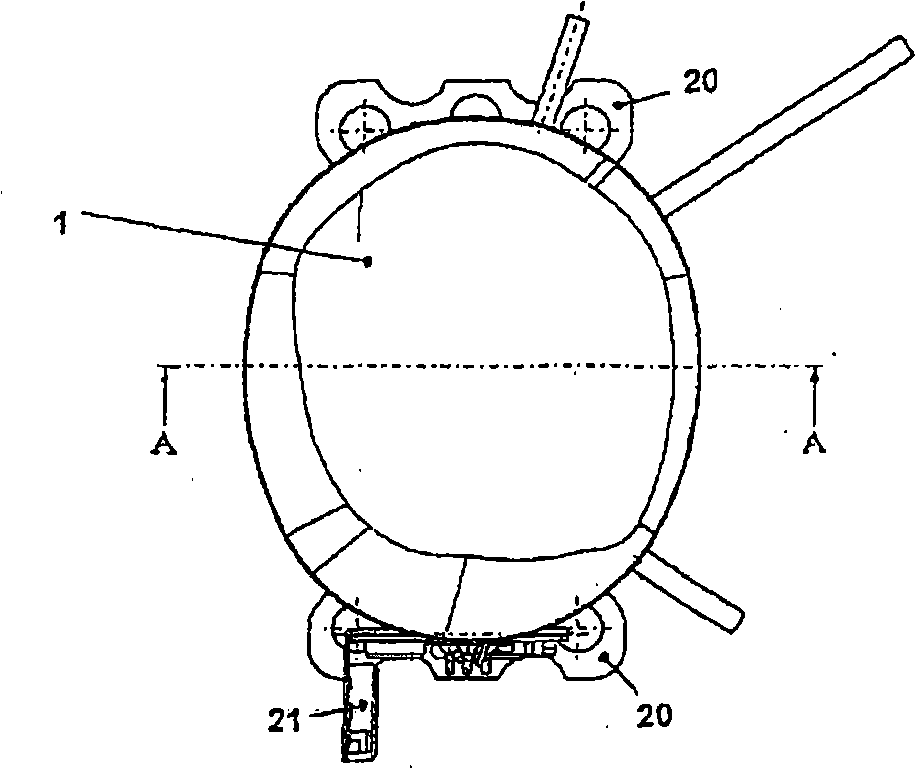

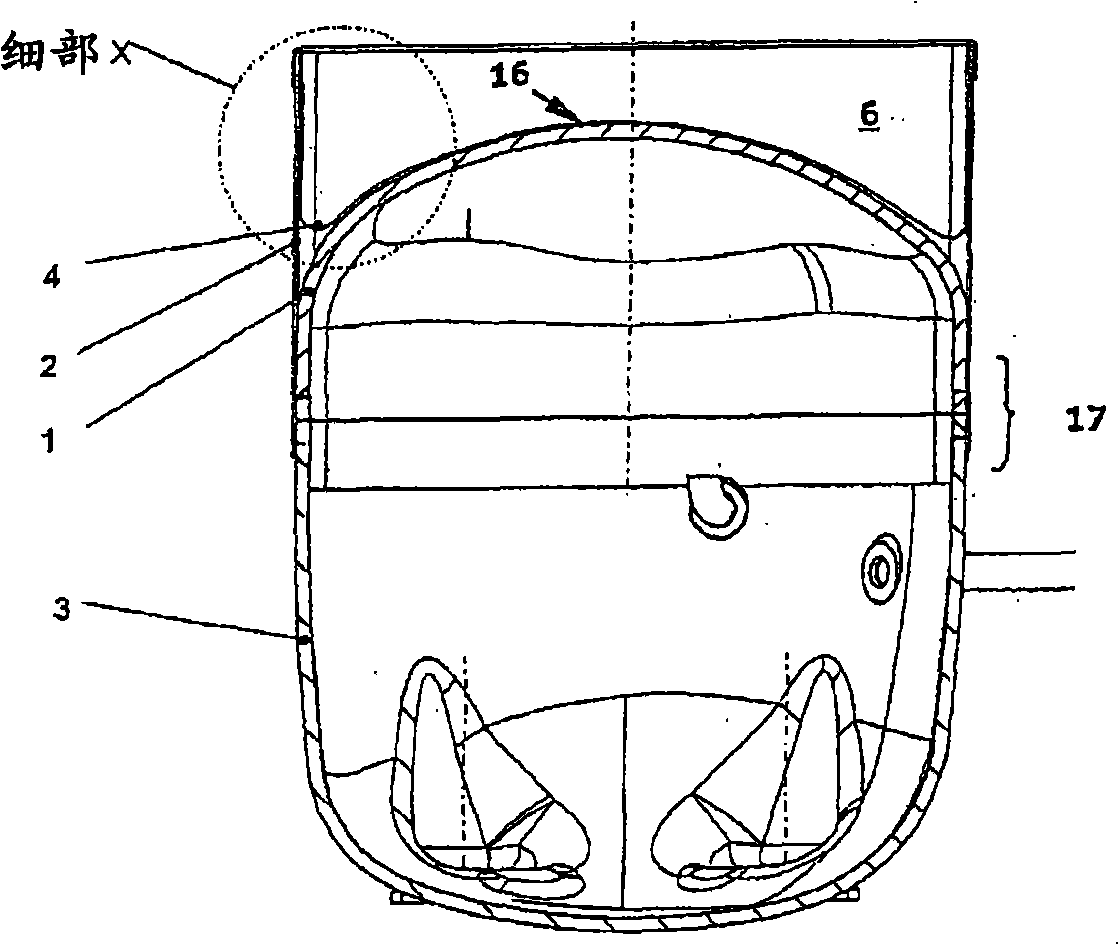

[0056] figure 1 Showing a small refrigerant compressor according to the invention, the compressor housing comprises a base part 3 and a cover part 1 which together define a hermetic chamber. A piston-cylinder arrangement (not shown) is located in this hermetic chamber closed by a compressor housing in a manner known per se, which is connected to a suction line and a pressure line through which refrigerant flows into the piston-cylinder arrangement , The pressure pipe leads the refrigerant compressed in the piston-cylinder device from the inside of the compressor housing.

[0057] The small refrigerant compressor itself is fastened to the compact refrigerator and is responsible for dissipating the heat from the cooling chamber of the compact refrigerator. Also shown are a mounting flange 20 and an adapter flange 21 with which the small refrigerant compressor is fastened to the small refrigerator and through which the small refrigerant compressor is powered.

[0058] As illus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com