Rolling angle measurement method and device based on grating

A roll angle measurement and measurement device technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problem of demanding working environment, limited measurement sensitivity, degree of polarization, laser frequency stability, signal-to-noise ratio of signal amplifier circuit, and difficult Application and other issues, achieve the effect of simple and compact optical structure, enhance anti-interference ability, and realize error separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

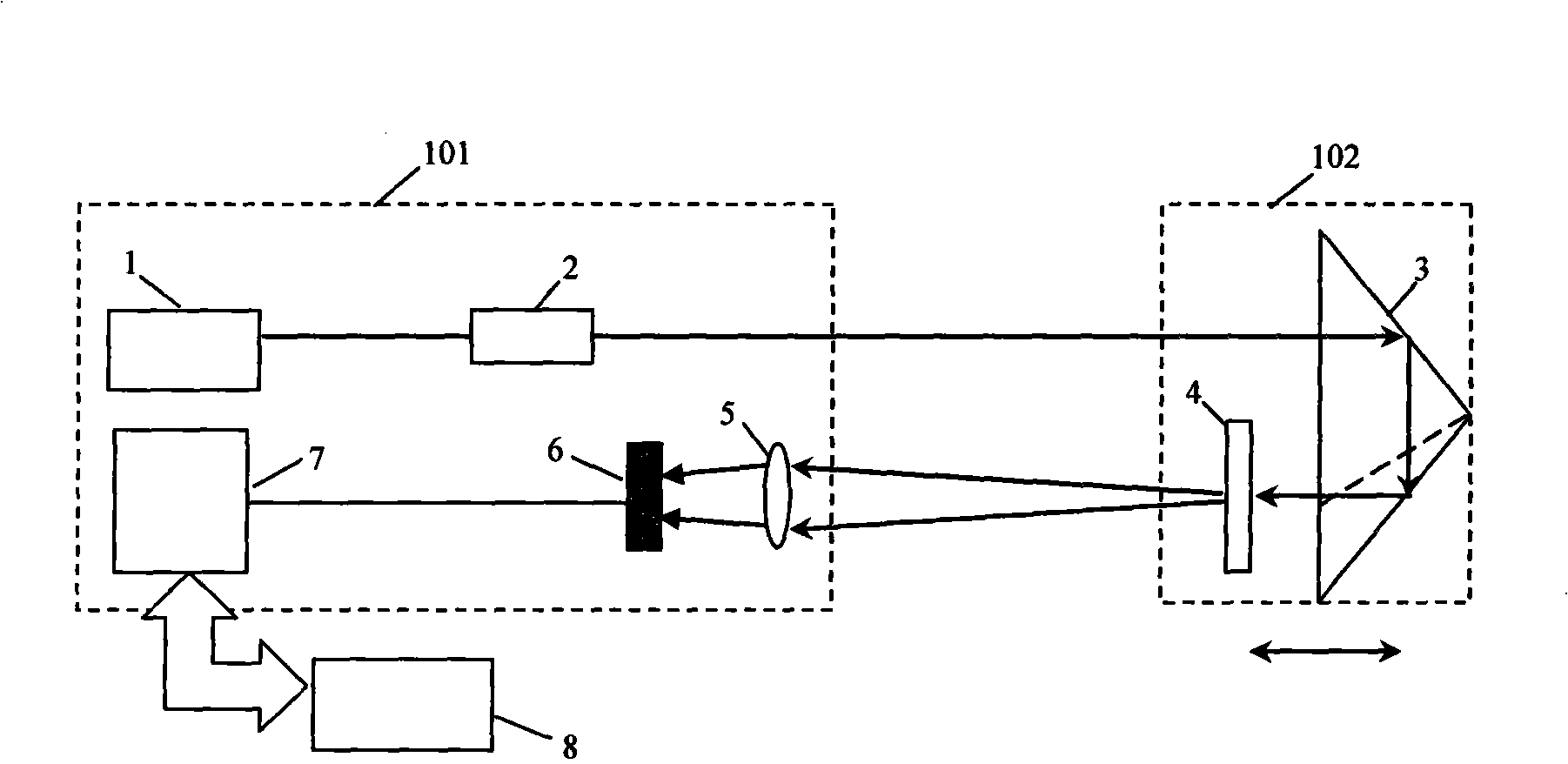

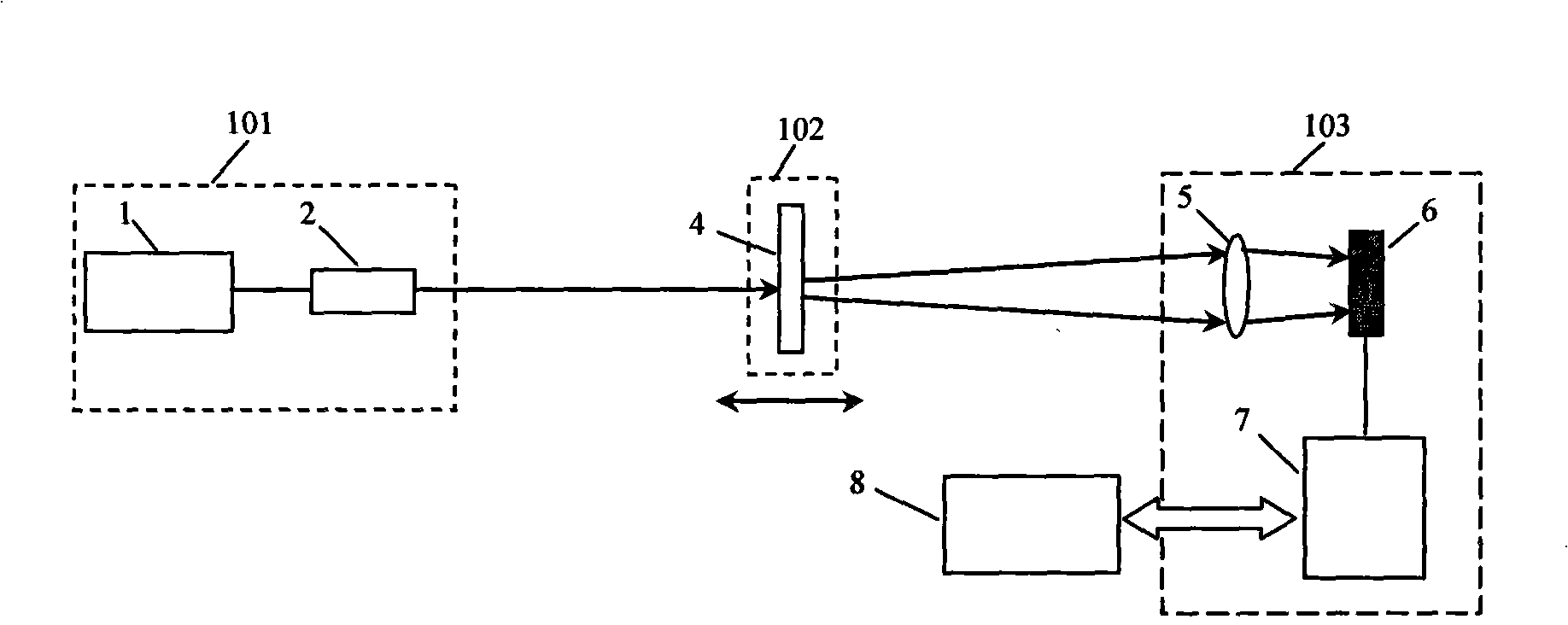

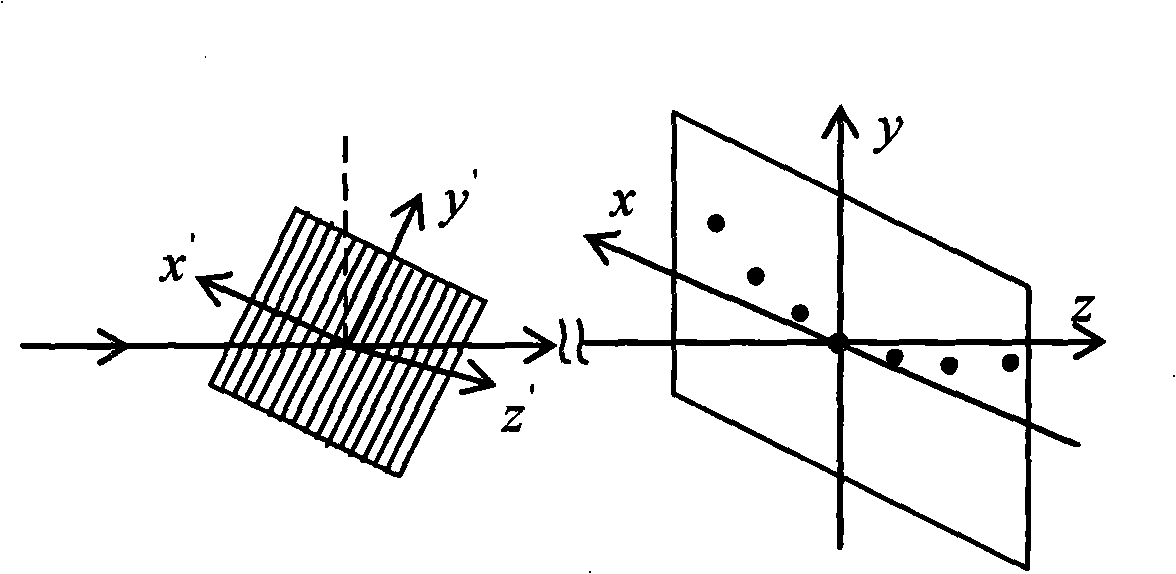

[0019] The method for measuring the roll angle based on the grating of the present invention is that the laser 1 emits laser light, which is collimated by the collimator lens 2 and then incident on the measurement platform. figure 1 After being reversed by the retroreflector 3 as shown, it passes through the grating 4, or as figure 2 As shown directly passes through the grating 4 to generate positive and negative first-order diffracted double beams. The above-mentioned laser 1 can be a He-Ne laser, a semiconductor laser or other types of lasers. The collimator lens 2 and the retroreflector 3 mentioned above can be selected according to the measurement requirements. The above-mentioned collimating lens 2 may be a single lens or a lens group. The above-mentioned retroreflector 3 may be a corner cube prism, a right-angle reflector or a cat's e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com