Composite fiber for whole time anti-cracking for concrete

A composite fiber and concrete technology, applied in the field of synthetic fibers for cement concrete and mortar, can solve the problems of inconvenient composite fiber system performance research, difficult-to-mix fiber products, complicated measurement, etc., to avoid connected cracks, improve impermeability, The effect of improving compactness

Inactive Publication Date: 2009-01-07

南京派尼尔科技实业有限公司

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

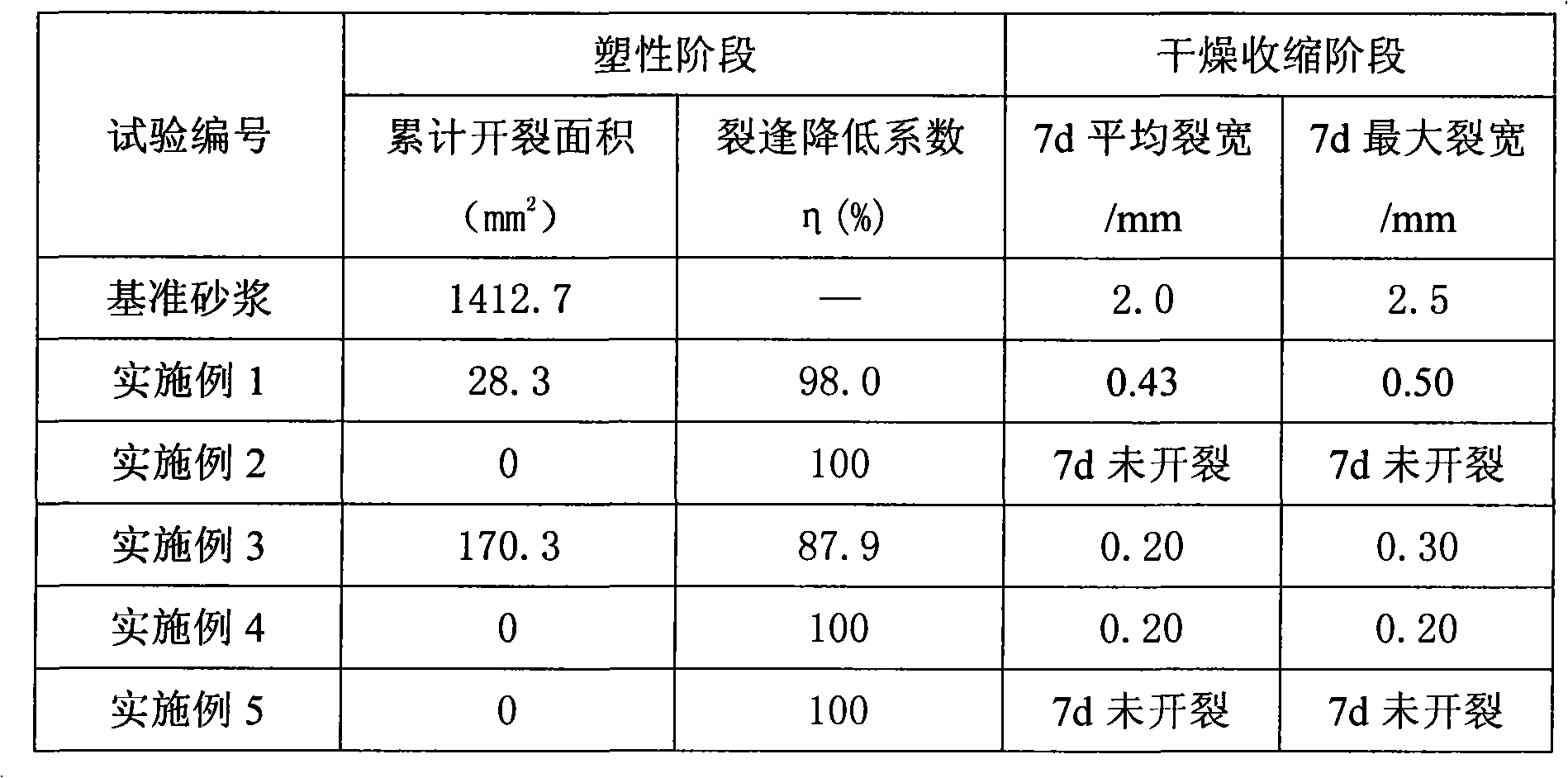

Embodiment 1

[0041] Example 1. Polyvinyl alcohol fiber 30%, length 5mm, polyacrylonitrile fiber 30% length 5mm, monofilament polypropylene fiber 40%, length 12mm.

Embodiment 2

[0042] Example 2. Carbon fiber 15%, length 6mm, polyamide fiber 40%, length 20mm, polyethylene fiber 45%, length 38mm.

Embodiment 3

[0043] Example 3. Kevlar aramid fiber 50%, length 6mm, polyacrylonitrile fiber 20%, length 12mm, reticulated polypropylene fiber 30%, length 20mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to duplex fiber used for resisting cracking of concrete throughout the course. The duplex fiber is prepared with the following synthetic fiber by weight: 15 to 50 percent of a high strength and high modulus synthetic fiber, 20 to 40 percent of a medium strength and medium modulus synthetic fiber, 20 to 45 percent of a low strength and low modulus synthetic fiber. The duplex fiber is prepared with fibers of different length, different elastic modulus and different strength of extension through compounding, thus forming a low strength and low modulus, medium strength and medium modulus, high strength and high modulus compound system. In this way, the duplex fiber not only has the advantages of various individual filaments but also has the superimposed effect of compounding of various fibers. Accordingly, the duplex fiber has synergistic actions in different periods when concrete is coagulated and hardened, which not only can prevent the plastic cracking of concrete, but also can effectively control the cracks during the hardening of concrete. In addition, the duplex fiber can effectively improve the toughness and the malleability of the concrete so that the durability of the concrete is significantly improved.

Description

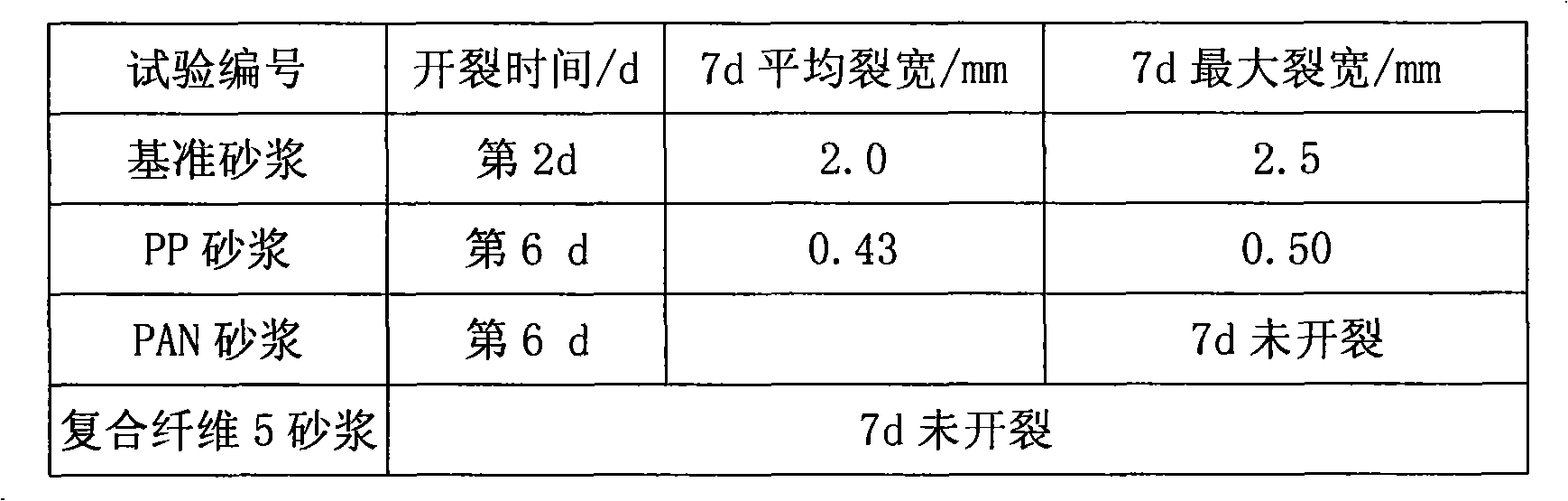

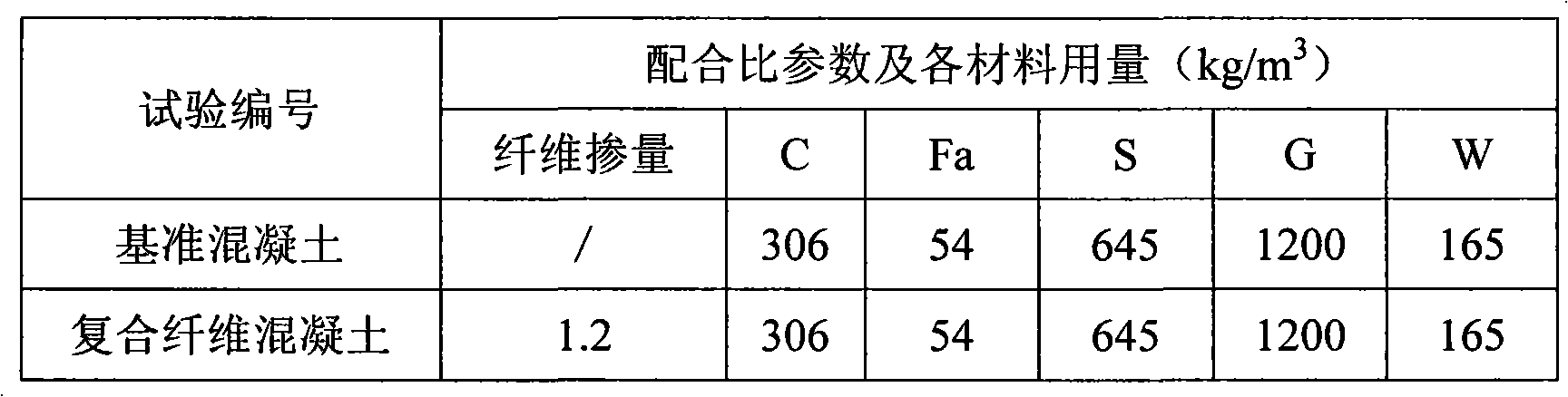

【Technical Field】 [0001] The invention relates to a composite fiber used for full-process anti-cracking of concrete, and belongs to the field of synthetic fibers for cement concrete and mortar. 【Background technique】 [0002] In recent years, synthetic fiber concrete has developed rapidly in China. Synthetic fibers represented by polypropylene fiber have been widely used in many fields such as highways, water conservancy, municipal administration, and industrial and civil construction. The improvement of concrete performance has been recognized by the civil engineering community. Generally affirmed and recognized. At the same time, the application technology and theoretical research of synthetic fibers have also made great progress. [0003] Studies have shown that there are three main functions of synthetic fibers in concrete: crack resistance, strengthening and toughening. These functions mainly depend on the mechanical properties of the fibers themselves. It is generally belie...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B16/06

CPCC04B2111/34C04B20/0068C04B28/02

Inventor 叶德平朱瑾

Owner 南京派尼尔科技实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com