Sewage treatment plant and process by SBR process

A sewage treatment device and process technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. Instability and other problems, to achieve the effect of saving electromechanical equipment, reducing equipment investment, and preventing sludge layer intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the drawings and embodiments: Embodiments:

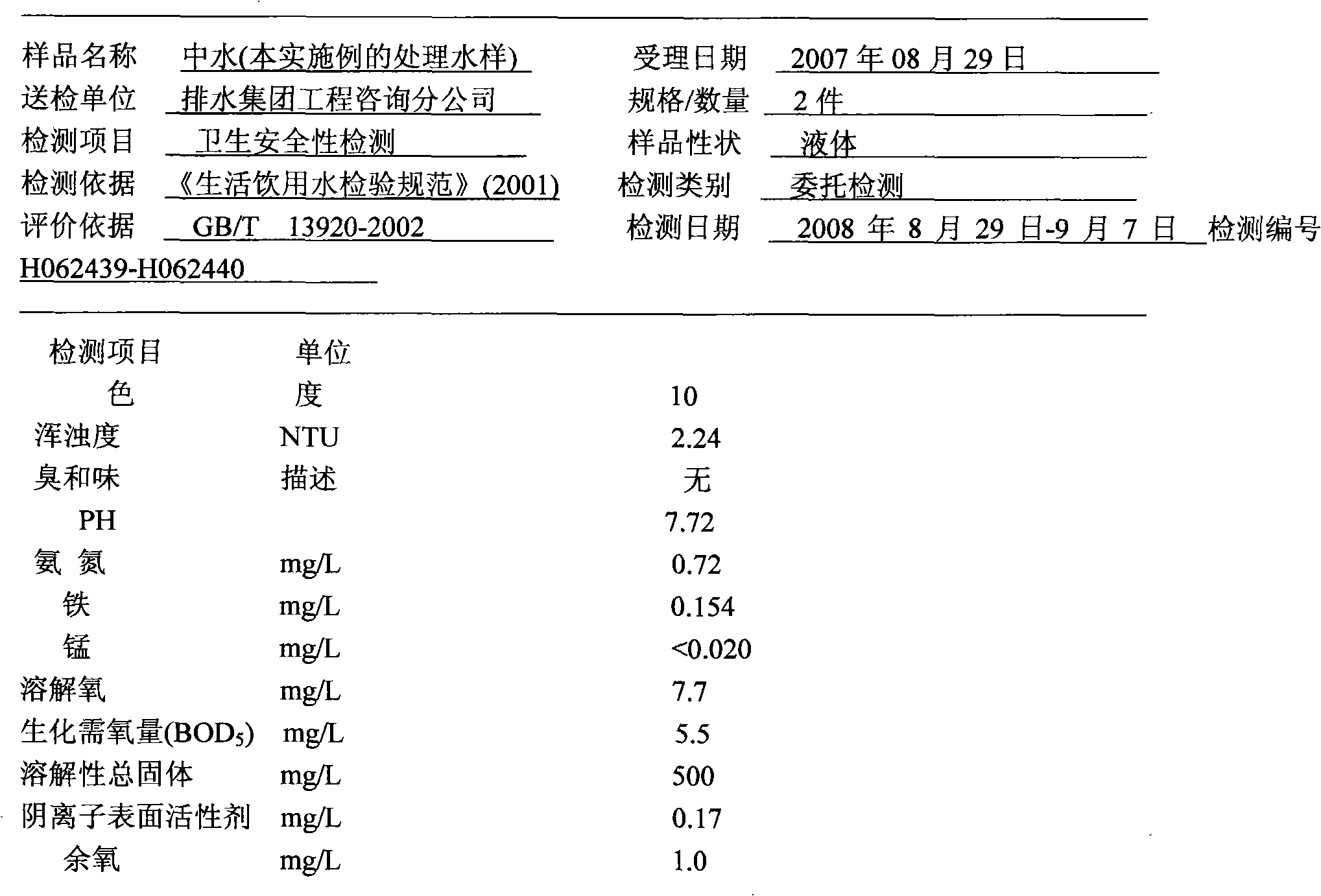

[0023] The present invention has been applied to engineering practice, including the sewage treatment station project (1000m 3 / d, completed and accepted in January 2003), Beijing Huairou Financial Cadre Training Center Sewage Treatment Station Project (600m 3 / d, completed and accepted in August 2006), now all have entered the normal use stage. The two sewage treatment stations are located in the courtyards of hotels and restaurants, and the surrounding environment is good and there is no bad smell. Since the sewage station has no complicated equipment, high degree of automation, simple operation and management, and good effluent quality, these two engineering examples have won unanimous praise from users.

[0024] Take the sewage treatment station project plan of the Beijing Huairou Financial Cadre Training Center as an example:

[0025] The design of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com