Plastics suction mould and mould making method thereof

A technology of plastic-absorbing molds and molds, which is applied in the field of plastic-absorbing molds in the trial production of automobiles. It can solve the problems that ordinary milling machines cannot be directly processed, reach automotive interior parts, and prolong the processing cycle. The effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

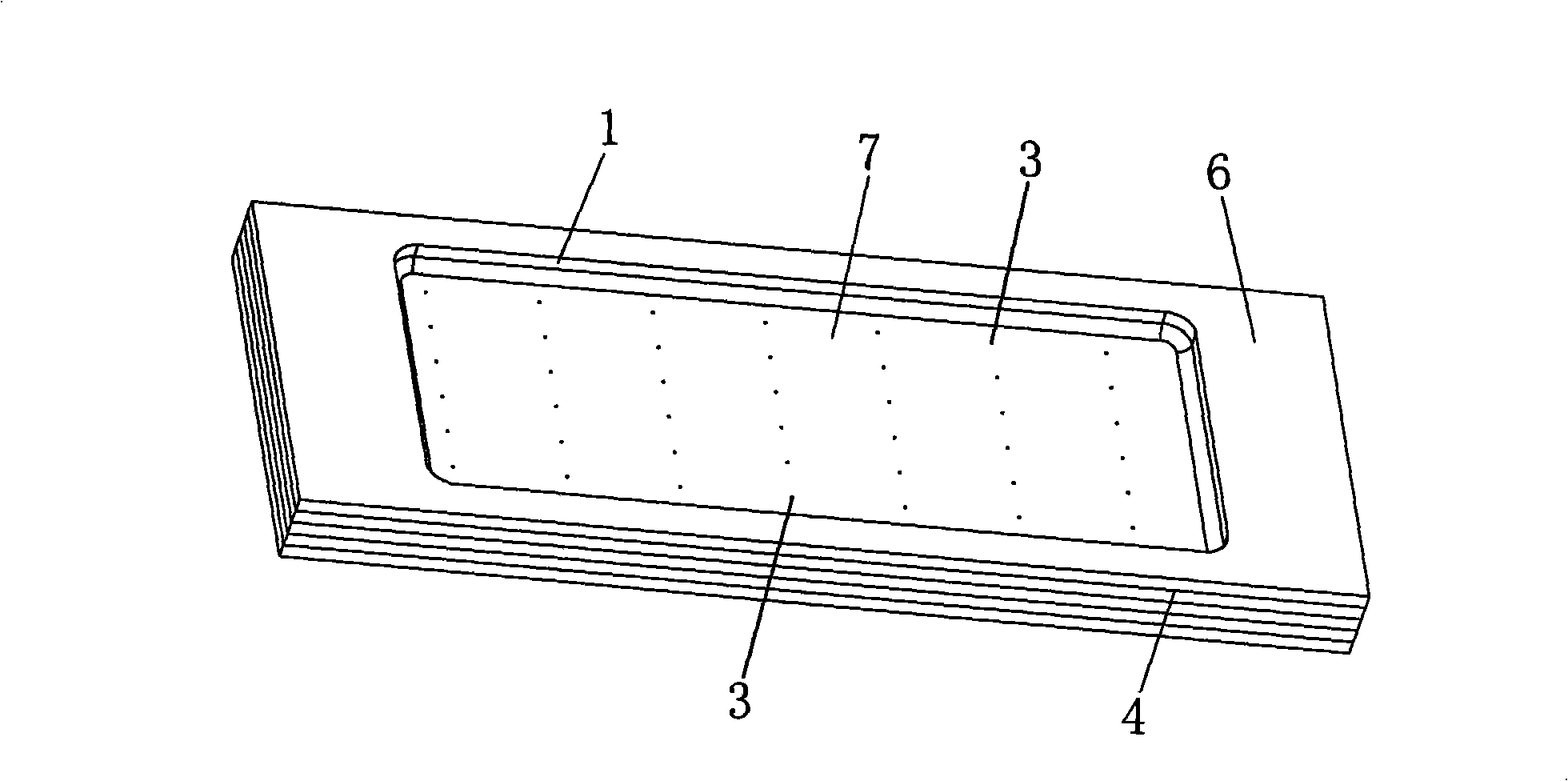

[0024] Such as figure 1 and figure 2 As shown, the blister mold of this embodiment is made of medium density fiberboard 1 , and the medium density fiberboard 1 has multiple layers, and the adjacent layers of medium density fiberboard 1 are bonded by white glue 4 . The blister mold has a front side 5 and a back side 6, the front side 5 is used to process a shape 2, the back side 6 is recessed with a pit 7, the pit 7 is an air chamber 7 that forms a sealing area during plastic suction, and the suction side The back side 6 of the plastic mold is also provided with a plurality of suction holes 3, and the suction holes 3 pass through the front side 5 and the air chamber 7 of the plastic suction mold.

[0025] Such as image 3 As shown, the molding method of the blister mold of the present embodiment includes the following steps:

[0026] a) Extract the three-dimensional digital model of the plastic part to be processed, and use CAM software (such as UG, Powermill, etc.) in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com