Method and apparatus for applying a layer of a separating agent to a substrate

A separation agent and substrate technology, which is applied to the device, coating, spraying device and other directions of coating liquid on the surface, can solve the problems of slow performance of the separation agent, unusable non-volatile components and decomposition products, and pollution of the vacuum chamber, etc. To achieve the effect of saving costs and solving the performance change of the separating agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

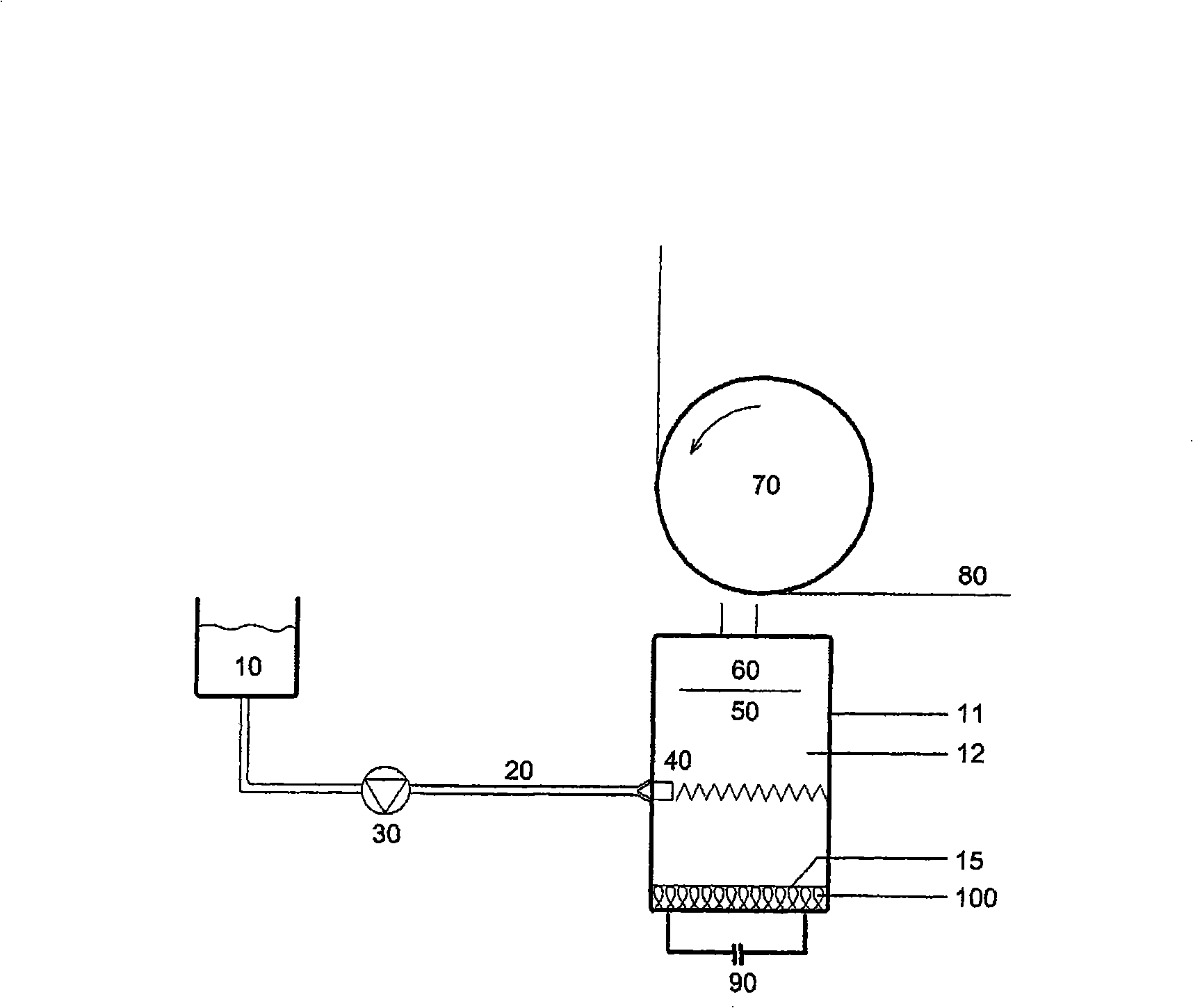

[0026] figure 1 The illustrated evaporator chamber 11 has an inner chamber 12 , which includes corresponding chamber walls, not denoted by reference numerals in the figures, and is equipped with nozzles 60 which are aimed at a moving strip-shaped substrate 80 . The nozzle 60 has an inner chamber-side opening through which the evaporated or vaporous separating agent is sprayed in the region of the substrate 80 . The substrate 80 is transported by a roller 70 arranged in the vacuum chamber of a not exactly shown coating system equipped with a metal evaporator, the direction of rotation of the roller 70 being indicated here by an arrow. Coating of aluminum is preferred, but not exclusive.

[0027] In the inner space 12 of the evaporator chamber 11 there is an evaporator plate 15 which can be heated by means of a heater 100 which is heated, for example, by means of a voltage source 90 . In addition, the chamber walls of the inner chamber 12 may be heated. In terms of location, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com