Product capable of control dissolving rate of medical orthopedic implant material and manufacturing method thereof

A technology of dissolution rate and implant material, applied in medical science, prosthesis, etc., can solve the problems of soft fibrous tissue ingrowth, fast dissolution rate, patient rejection, etc., and achieve the effect of easy setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

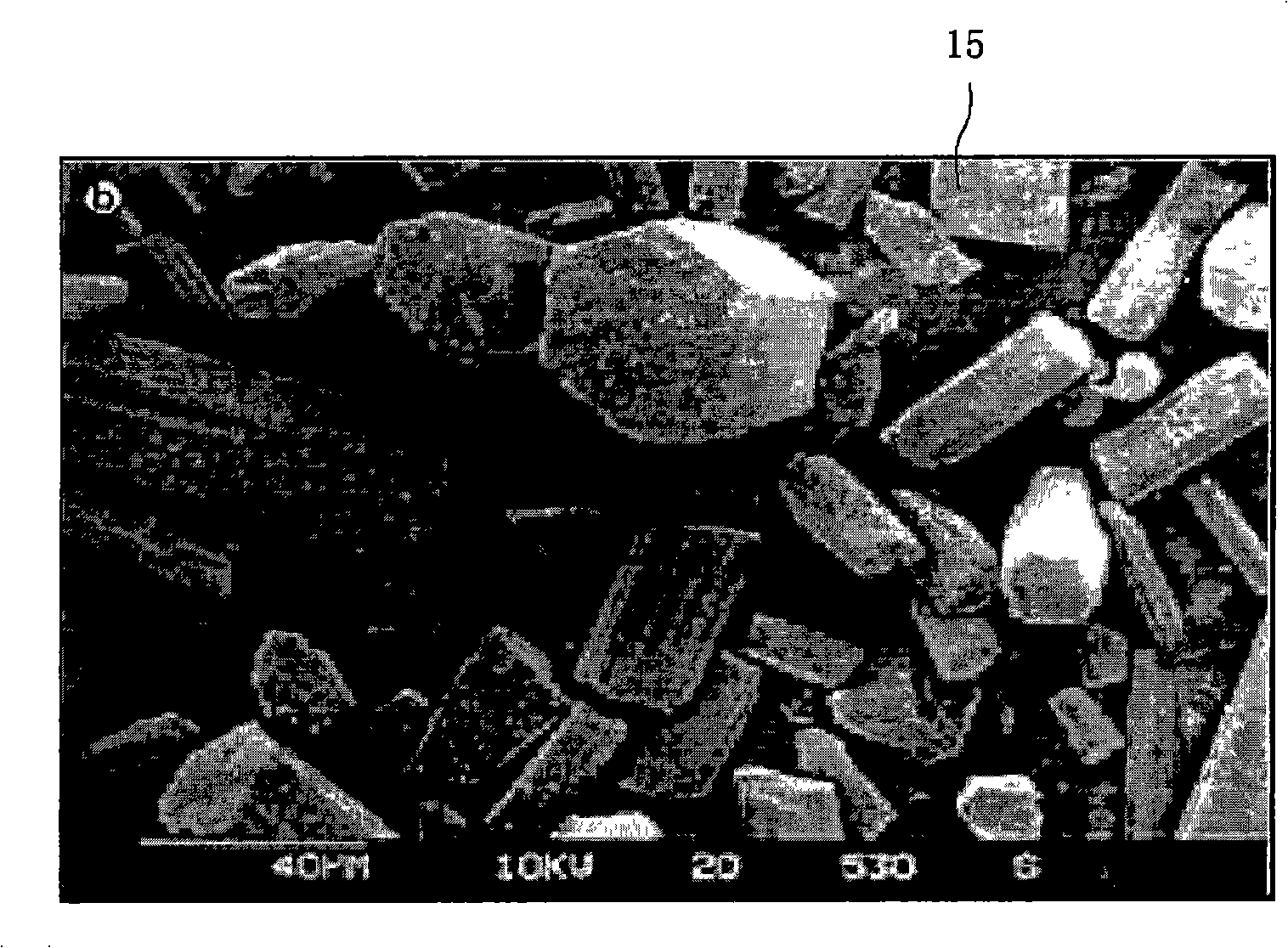

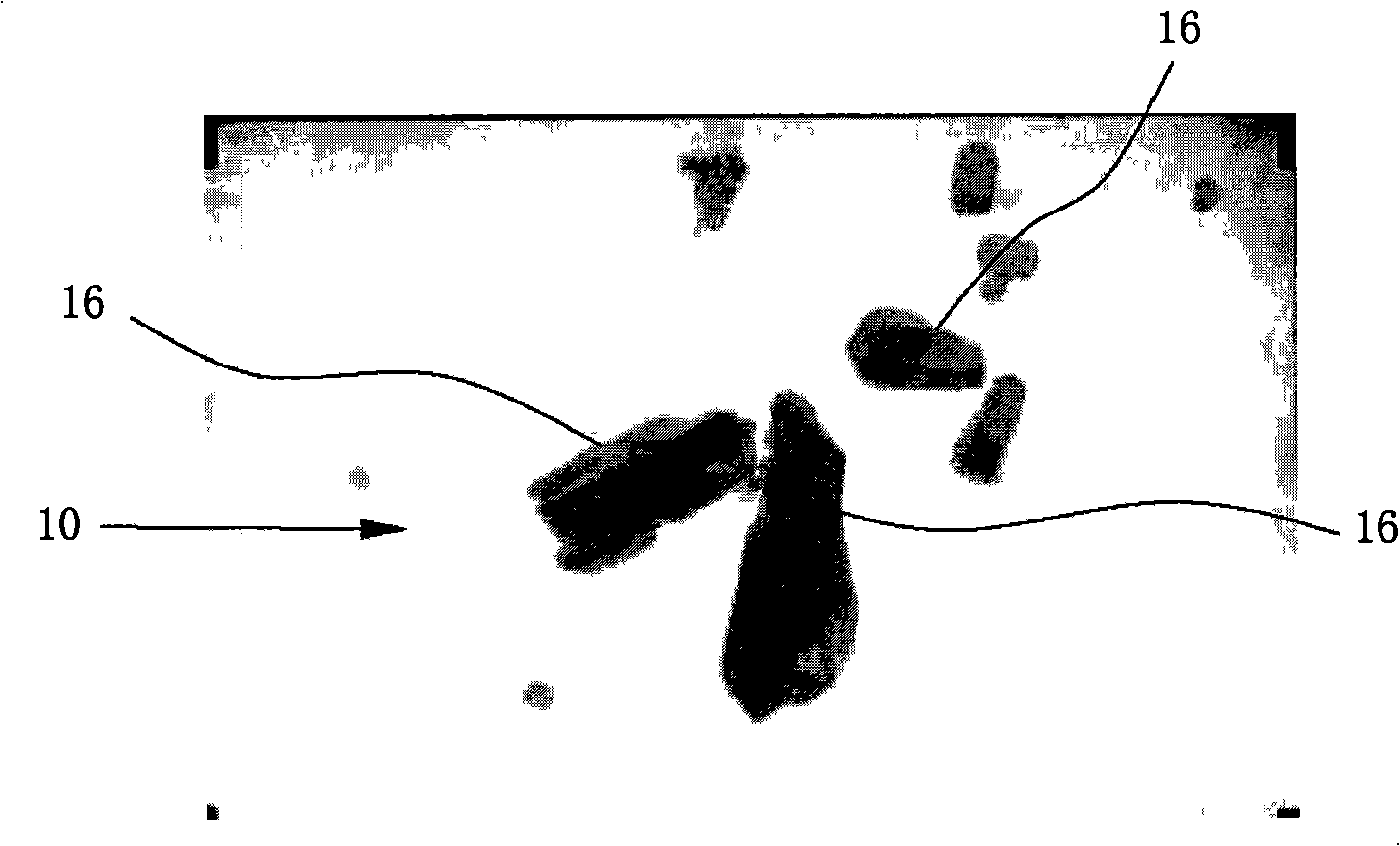

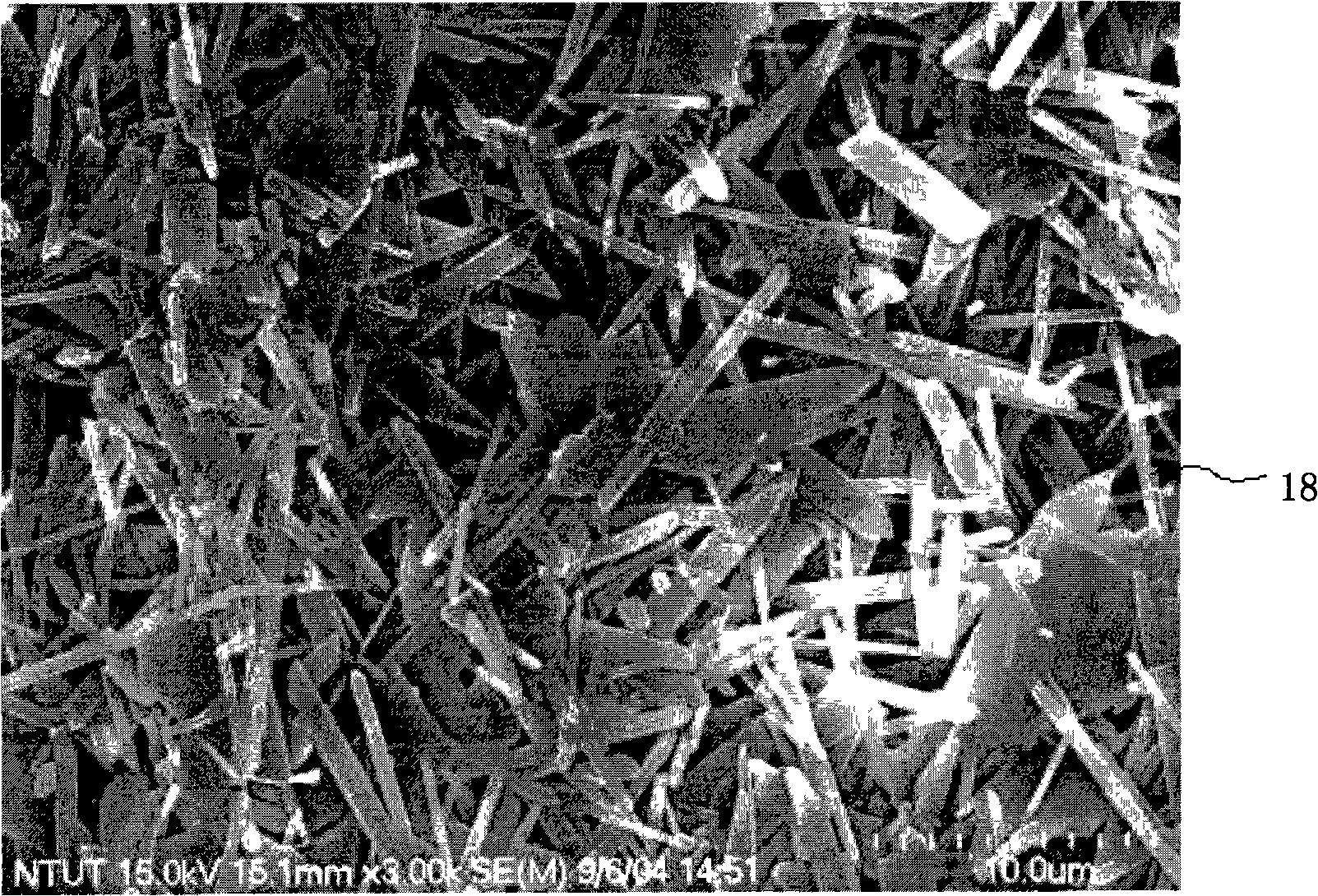

[0054] Please refer to Figure 1A Fig. 10 is an embodiment of the present invention, wherein the detailed description is as follows: (1) the calcium sulfate hemihydrate powder is passed through a powder vibration sieving machine, and the powder is sieved. Sieve through the standard analytical sieves 100, 120, 100, 325, 400, 500 under the specifications of the American Society for Testing and Materials (ASTM) for 48 hours. The whole process needs to be carried out at a relative humidity of 10% and an operating temperature of 5°C to avoid chemical changes of the powder due to exposure to air. (2) After the sieved calcium sulfate hemihydrate powder is analyzed by laser particle size, a specific proportion of particle size powder is taken for purification. (3) Use multiple heat treatment conditions to set the furnace, and modify the material composition in the furnace. Since calcium sulfate hemihydrate mostly has calcium sulfate dihydrate formed by the rapid reaction between α an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com