Crane remote wireless parallelling control system and method

A control system, remote wireless technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as inability to lift super long workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

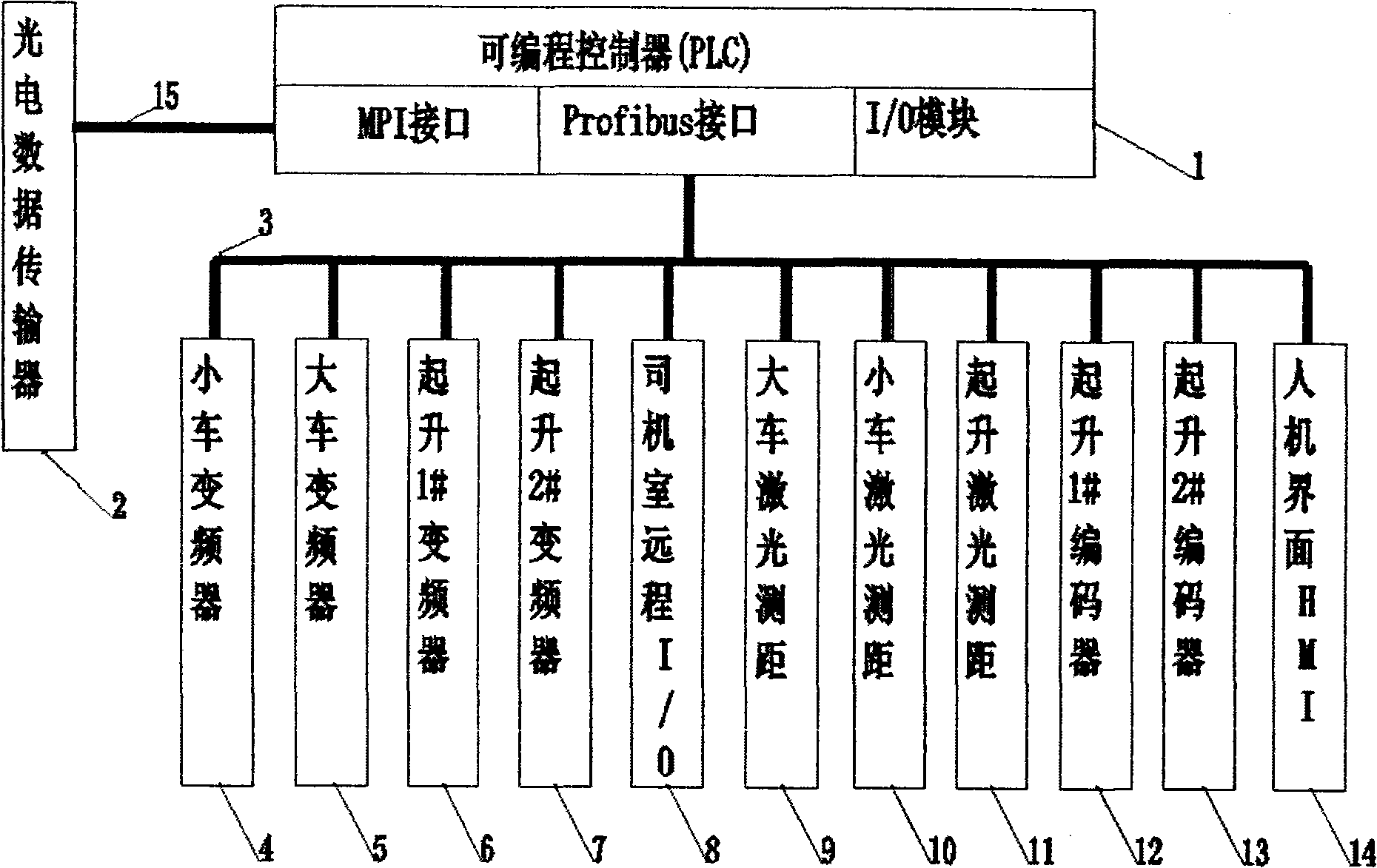

[0034] Such as figure 1 and image 3 As shown, the crane remote wireless paralleling control system in this embodiment includes a programmable logic controller (PLC) 1 including a digital input / output module and an analog signal input / output module, a human-machine interface (HMI) 14, and a trolley Inverter 4, crane inverter 5, hoisting 1# inverter 6, hoisting 2# inverter 7 and the crane control system of remote input and output module (I / O) 8 of the driver's cab, which also includes:

[0035] 1) The cart laser rangefinder 9 used to measure the running distance of the large workshop of the crane. The cart laser rangefinder 9 is composed of a cart laser rangefinder transmitter 9-1 and a cart laser reflector 9-2. The laser ranging transmitters 9-1 are respectively installed at the two ends of the girder between at least two parallel cranes, and the cart laser reflectors 9-2 are installed at the corresponding positions at the two ends of the girder;

[0036] 2) The trolley lase...

Embodiment 2

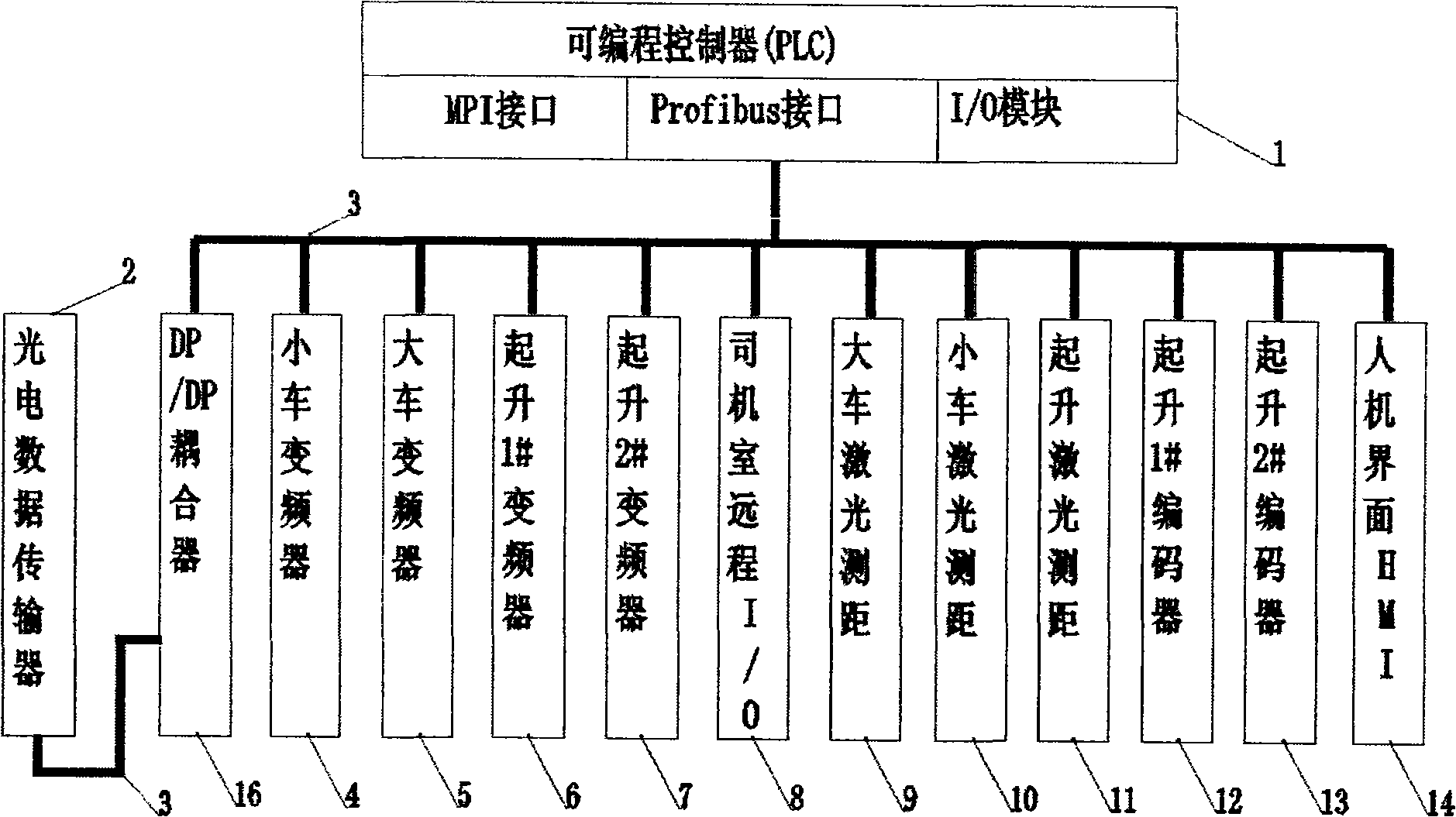

[0058] Such as figure 2 As shown, the high-speed network connection between the cranes of the parallel control system in this embodiment can also use a DP / DP coupler 16, and the DP / DP coupler 16 is connected with a programmable controller (PLC) 1 through a Profibus bus 3, and the DP The / DP coupler 16 is connected to the network with the crane to be paralleled through the wireless photoelectric data transmission module (ISD) 2 .

[0059] Such as Figure 4 As shown, the method for realizing the remote wireless paralleling control system of the crane comprises the following steps:

[0060] 1) Establish a data area for storing the running status of the crane on the vehicle;

[0061] 2) Establish a data area for storing the running status of other cranes that need to be paralleled;

[0062] 3) Send the data stored in the data area of the vehicle to other cranes that need to be combined;

[0063] 4) Receive the data sent by other cranes that need to be paralleled and store i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com