Dual roller rail clamping type falling-proof scaffold

A rail-clamping, anti-falling technology, which is applied to the scaffolding of building structure support, building structure support, building structure support, etc., can solve the problems affecting construction safety, many parts, and the safety of construction personnel cannot be guaranteed. Avoid the effect of free fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

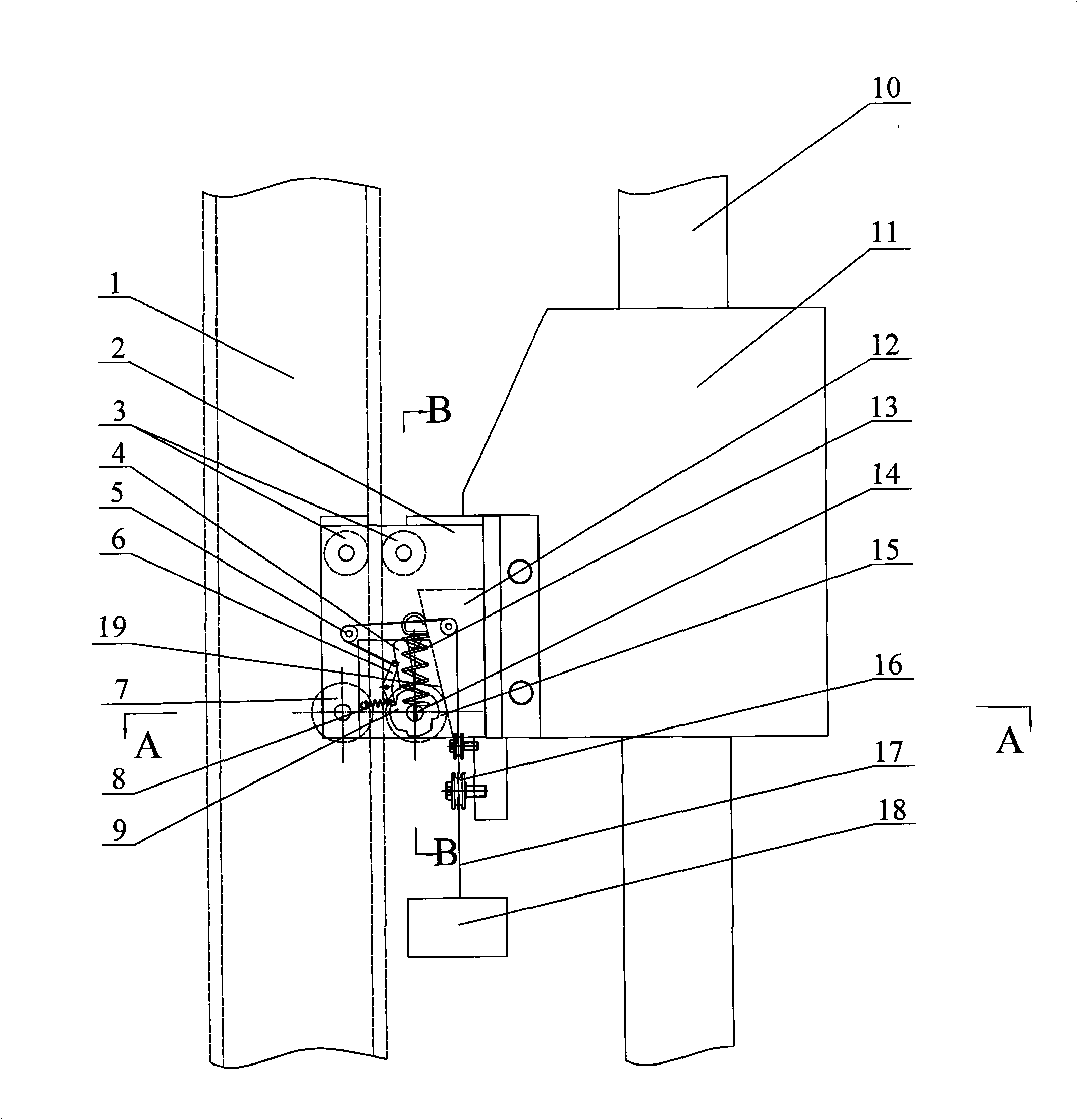

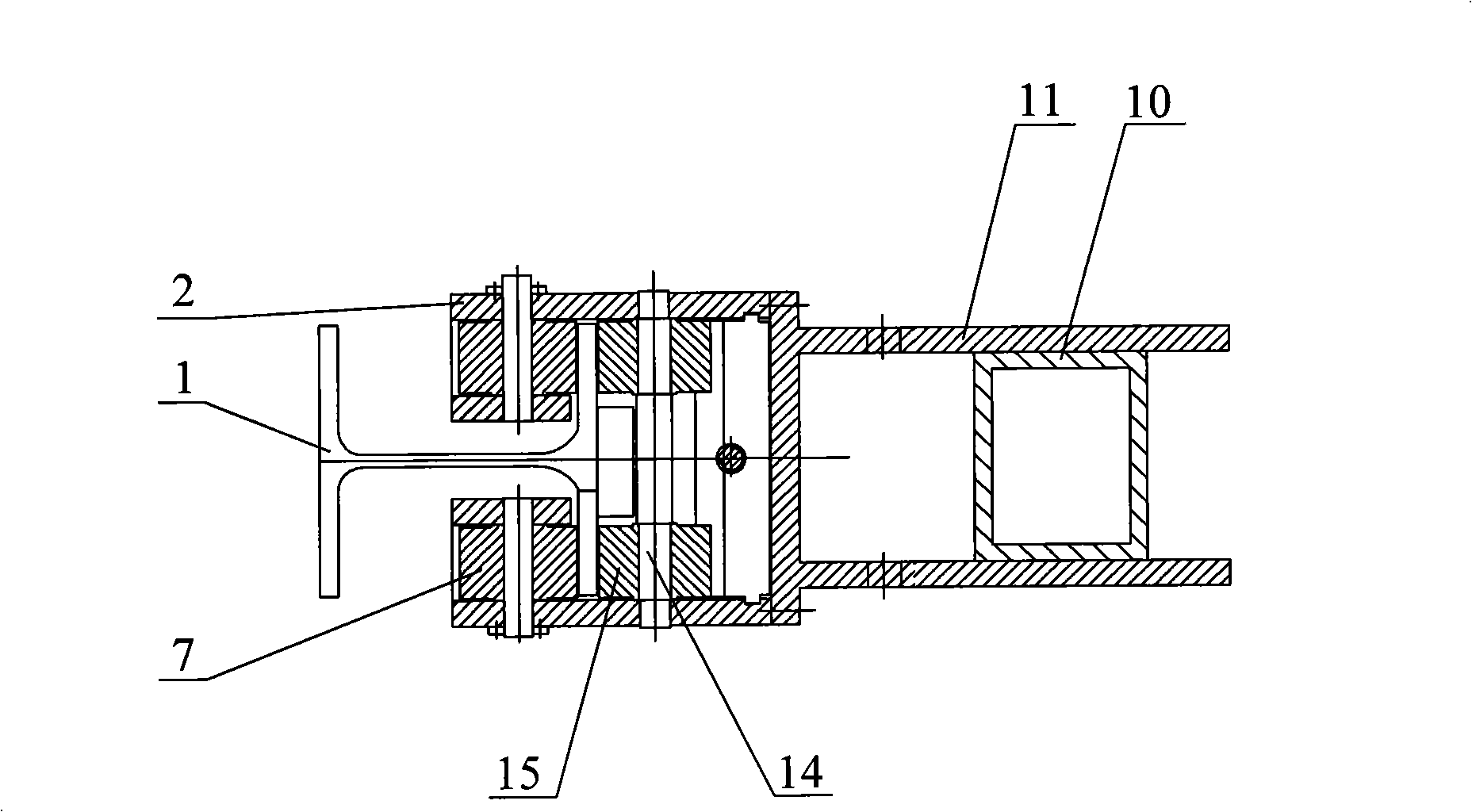

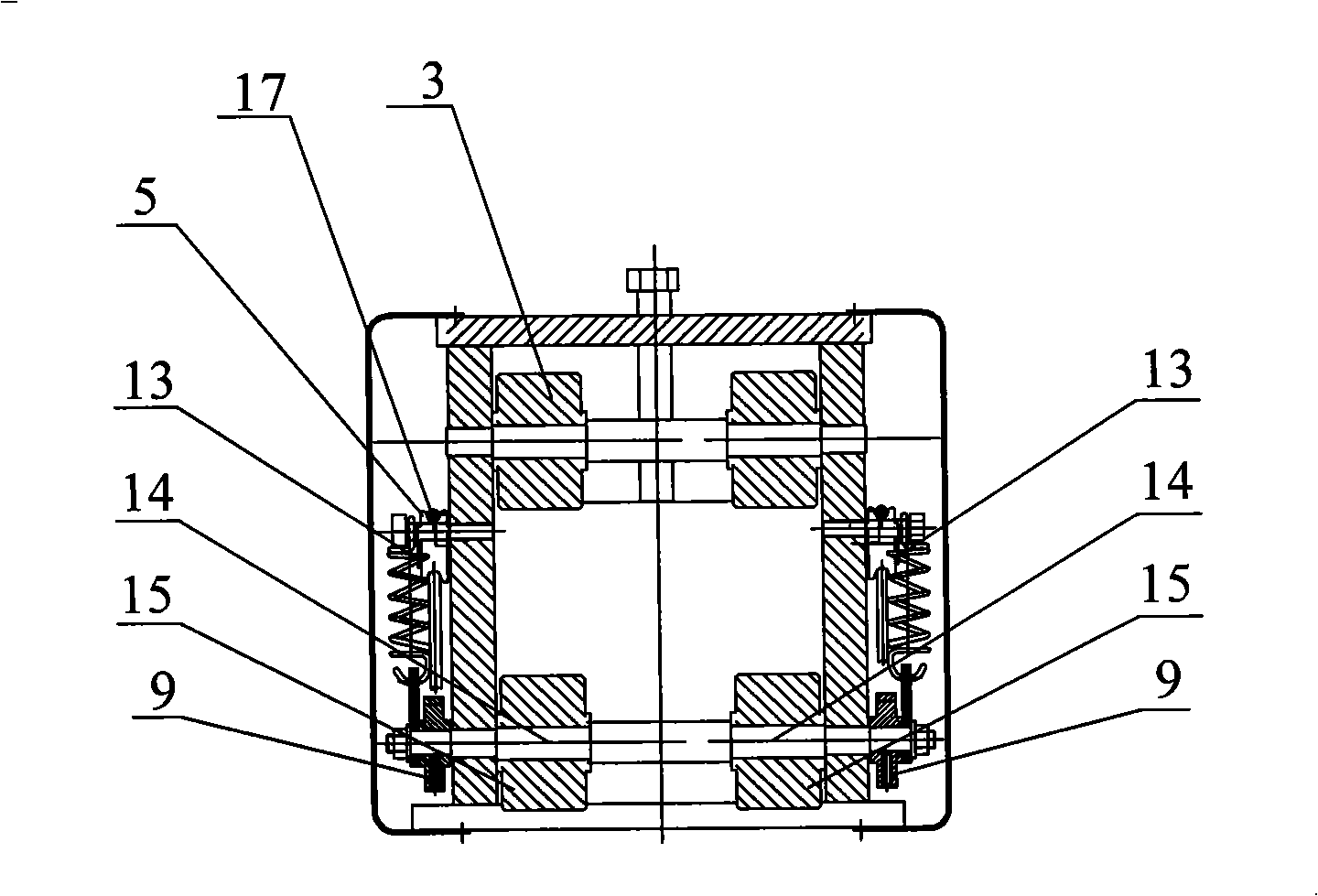

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0011] As shown in the figure: it includes a frame body 10 and a connecting frame 11, the connecting frame 11 is fixedly connected with a brake box 2, one side of the frame body 10 is fixedly provided with a guide rail 1, and the guide rail 1 is inserted into the brake box 2 to make On the opposite side wall of moving case 2, offer inclined guide groove 4, slide frame is provided with brake wheel shaft 14 in guide groove 4, is provided with brake wheel 15 on brake wheel shaft 14, and brake wheel 15 surfaces are rough, in The brake box 2 on the side of the brake wheel 15 is equipped with a back pressure wheel 7, and the back pressure wheel 7 relies on the side wall of the guide rail 1, and the brake wheel 15 and the back pressure wheel 7 clamp the guide rail 1 therein A friction block 12 is provided on the other side of the brake wheel 15, the distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com