Low resin mica tape organosilicon adhesive and method for preparing same

A technology of less glue mica and silicone adhesives, applied in the direction of adhesives, coatings, etc., can solve the problems of poor compatibility between silicone resin and silicone rubber, and achieve improved similarity, good compatibility, and good integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

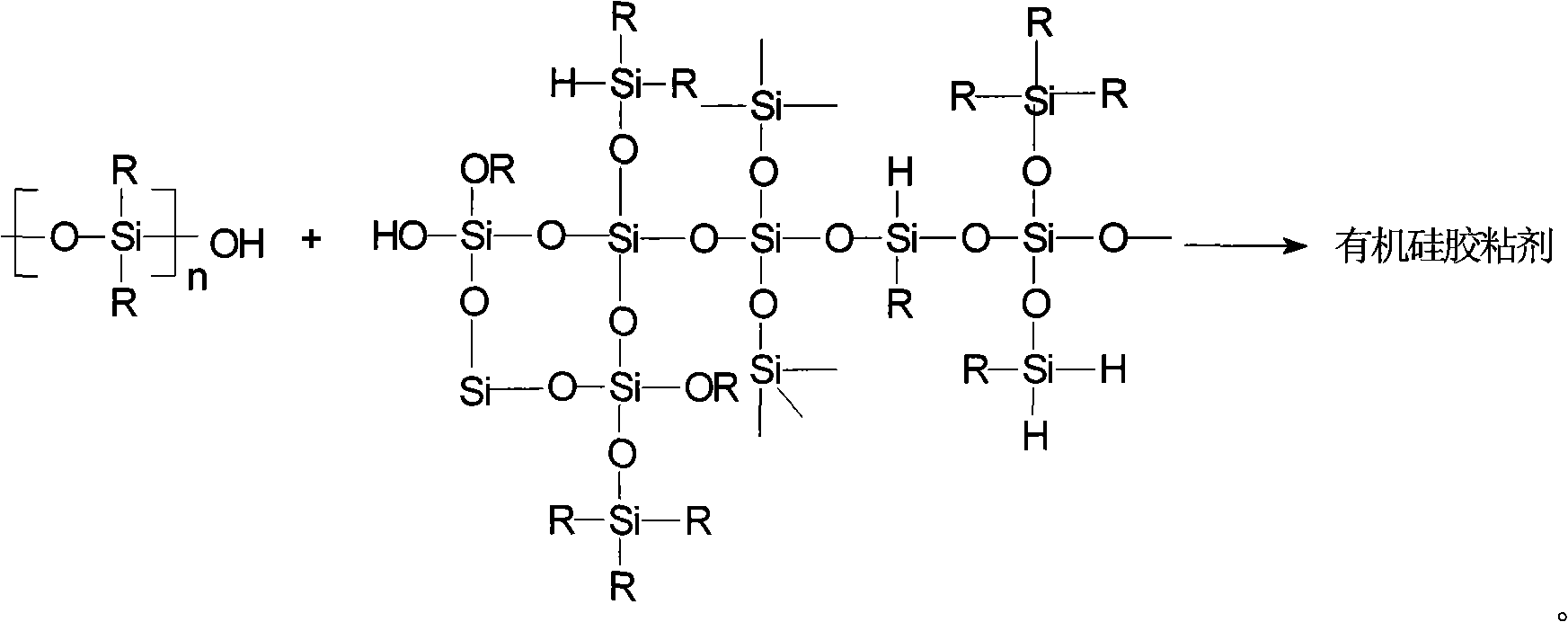

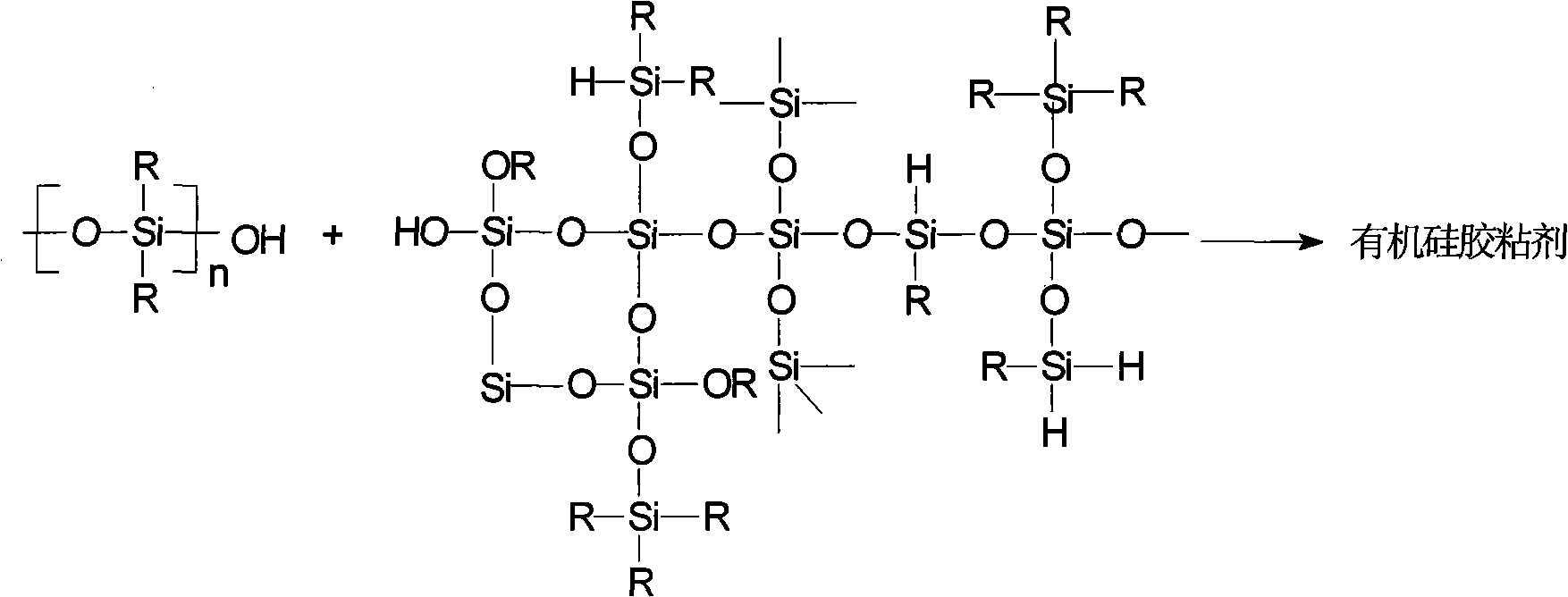

[0020] Use the Si-H bond-containing MQ resin to modify the less colloidal mica with organic silicone adhesive. By adding the silicon-hydrogen bond (Si-H)-containing MQ resin to the high-molecular-weight silicone rubber to improve the silicone rubber and silicone Compatibility of the resin, adding MQ resin to the silicone rubber will not only form a jujube core structure, with high cohesion, and there are silicone-hydrogen bonds in the modified less colloidal mica with organic silicone adhesive, which will be cured in the subsequent immersion The process reacts with the active groups in the silicone resin impregnating varnish together to form physical and chemical compatibility, and an insulating system with good impregnation effect is obtained.

[0021] The specific modification scheme of less colloidal mica with organic silicone adhesive is as follows:

[0022] (1) Preparation of high molecular weight silicone rubber;

[0023] Take 100 parts of octamethylcyclotetrasiloxane, 8 par...

example 2

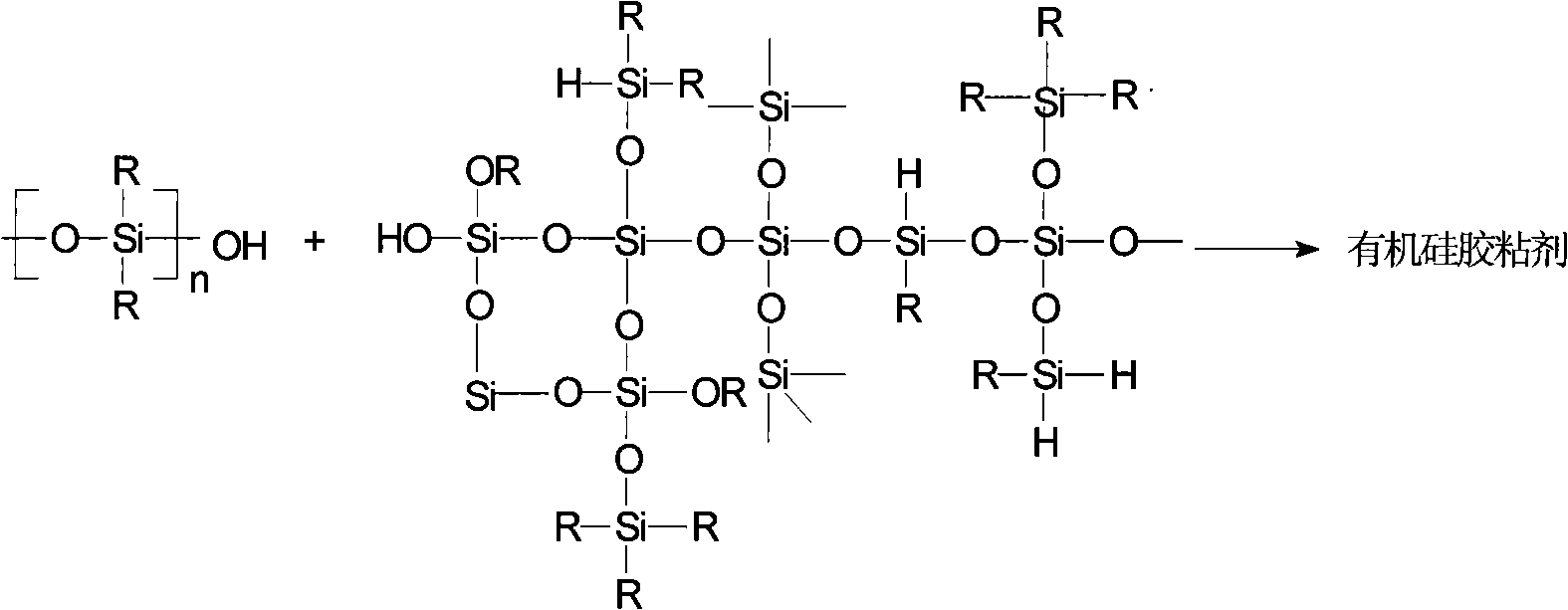

[0031] Use the Si-H bond-containing MQ resin to modify the less colloidal mica with organic silicone adhesive. By adding the silicon-hydrogen bond (Si-H)-containing MQ resin to the high-molecular-weight silicone rubber to improve the silicone rubber and silicone Compatibility of the resin, adding MQ resin to the silicone rubber will not only form a jujube core structure, with high cohesion, and there are silicone-hydrogen bonds in the modified less colloidal mica with organic silicone adhesive, which will be cured in the subsequent immersion The process reacts with the active groups in the silicone resin impregnating varnish together to form physical and chemical compatibility, and an insulating system with good impregnation effect is obtained.

[0032] The specific modification scheme of less colloidal mica with organic silicone adhesive is as follows:

[0033] (1) Preparation of high molecular weight silicone rubber;

[0034] Take 120 parts of octamethylcyclotetrasiloxane, 3 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com