Full automatic stone slab edger unit

A technology for edging equipment and stone plates, which can be used in grinding/polishing equipment, metal processing equipment, machine tools suitable for grinding workpiece edges, etc., and can solve problems such as unevenness, poor grinding quality, and unstable clamping. , to achieve the effect of stable operation, good grinding quality and stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

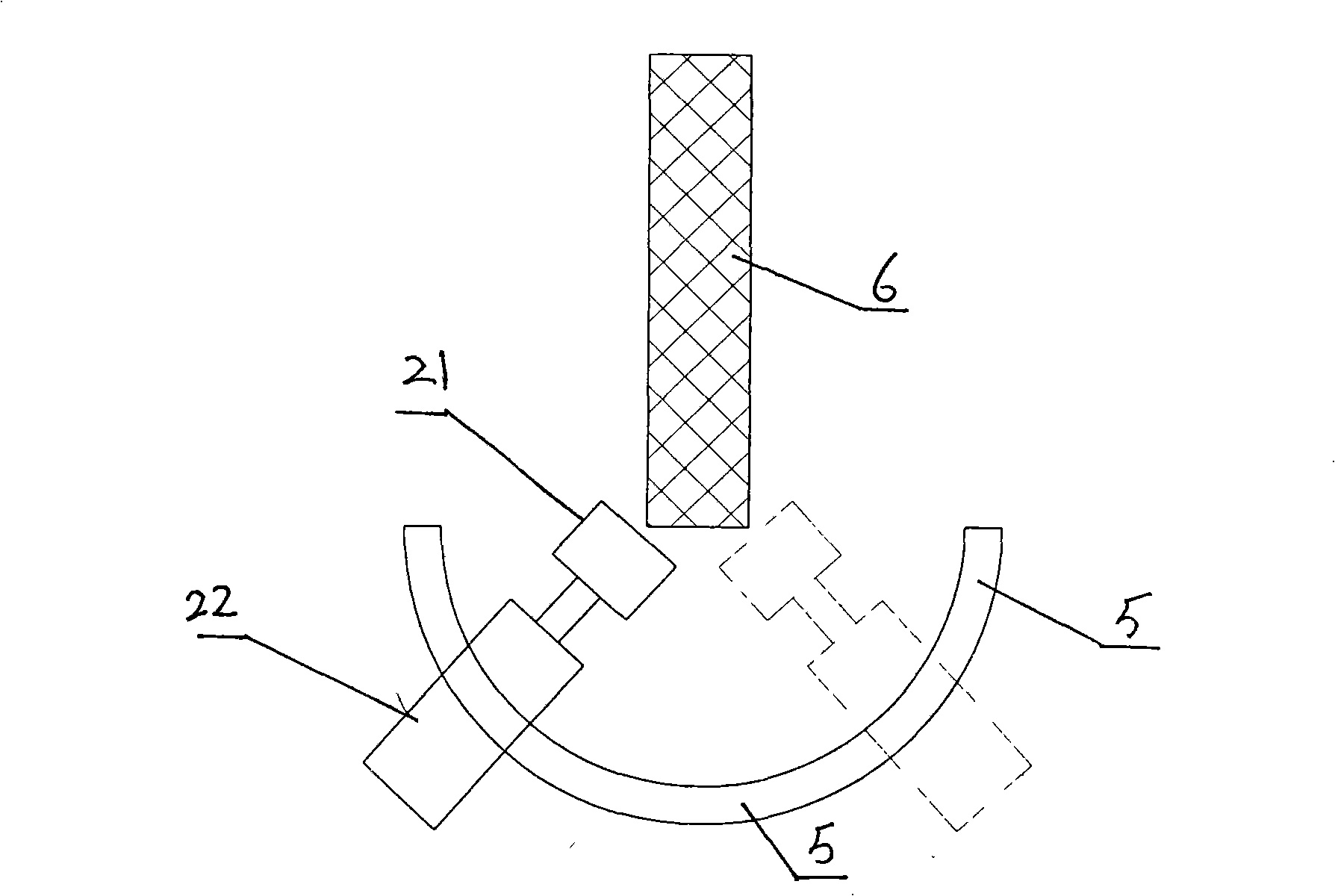

[0019] figure 1 , figure 2 The shown automatic stone slab edging equipment includes a frame 1, on which a grinder and a clamping drive mechanism are installed, the grinder is installed below the clamping drive mechanism, and the grinder includes a grinding wheel 21 and The motor 22 that drives the grinding wheel to rotate at a high speed; the clamping drive mechanism includes two rows of vertically installed clamping rollers, wherein the support of the first row of clamping rollers 3 is fixedly installed on the frame, and the first row of clamping rollers 3 A drive motor is provided, the first row of clamping rollers is a metal roller, and the inner side of the first row of clamping rollers is cushioned with a rubber conveyor belt 31 . The second row of clamping rollers 4 is a rubber pressure roller, and the support of the rubber pressure roller 4 can be mounted on the frame in a horizontally sliding manner, and a lateral thrust cylinder 41 is provided corresponding to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com