Gas film quick continuous casting device and method in magnetostatic field

A technology of static magnetic field and gas film, which is applied in the field of metallurgy, can solve the problems of no obvious increase in casting speed, expensive porous graphite ring, and affecting the quality of cast billets, so as to ensure uniformity and stability, facilitate processing, and improve surface quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

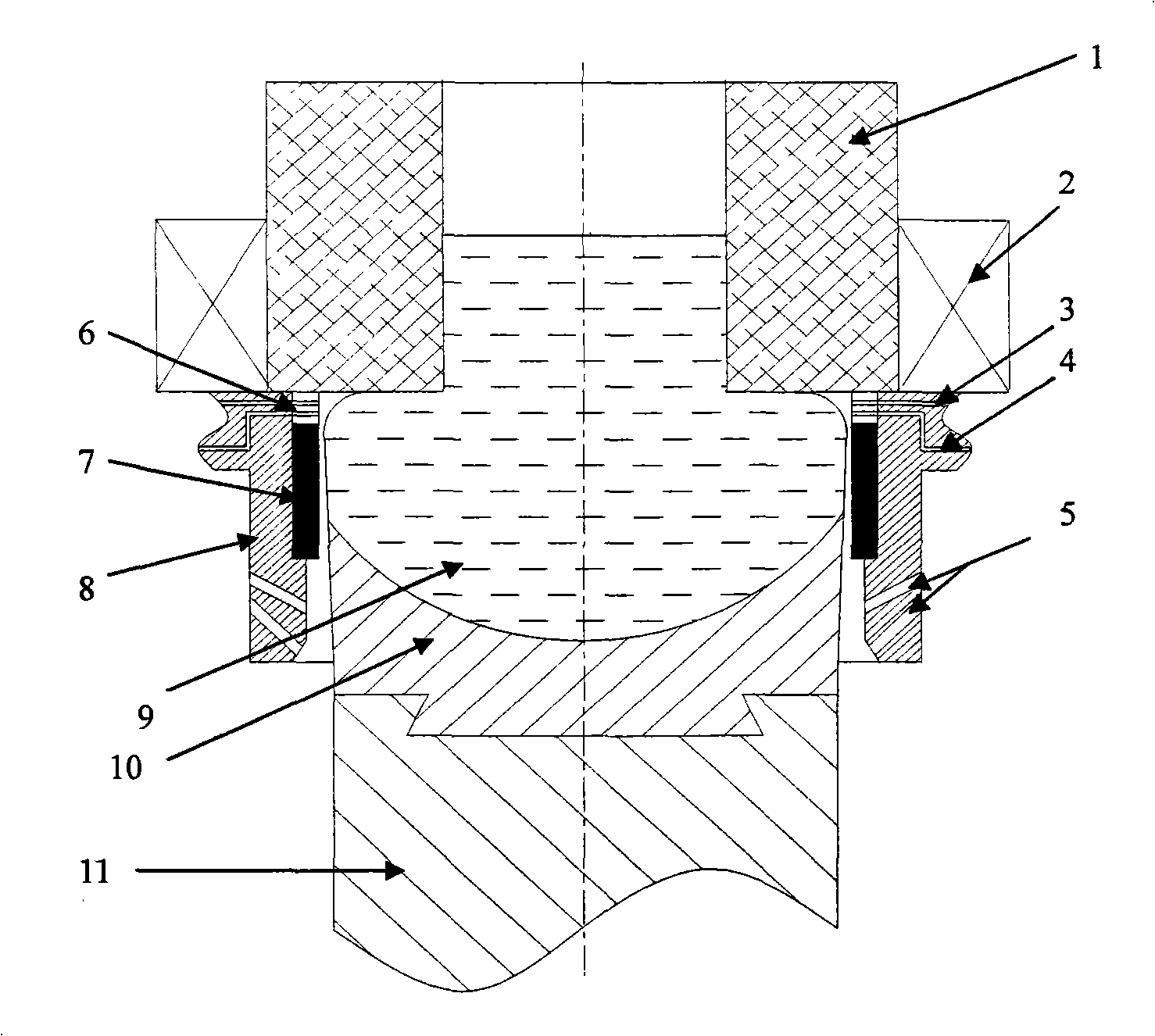

[0019] Gas film rapid continuous casting device such as figure 1 As shown, the hot top is surrounded by an induction coil, and an oil and gas ring is arranged between the outlet of the hot top and the graphite ring. The material is austenitic stainless steel. The oil and gas ring is provided with oil inlet and air inlet holes, and the oil inlet and The air inlet can pass oil and gas from the outside of the crystallizer to the crystallizer through the oil and gas channels on the crystallizer; the outside of the oil-gas ring and the graphite ring are connected to the crystallizer, and the crystallizer is provided with a double at the lower part of the joint with the graphite ring. The angle between the upper cooling water channel and the crystallizer wall is 60°, and the angle between the lower cooling water channel and the crystallizer wall is 30°.

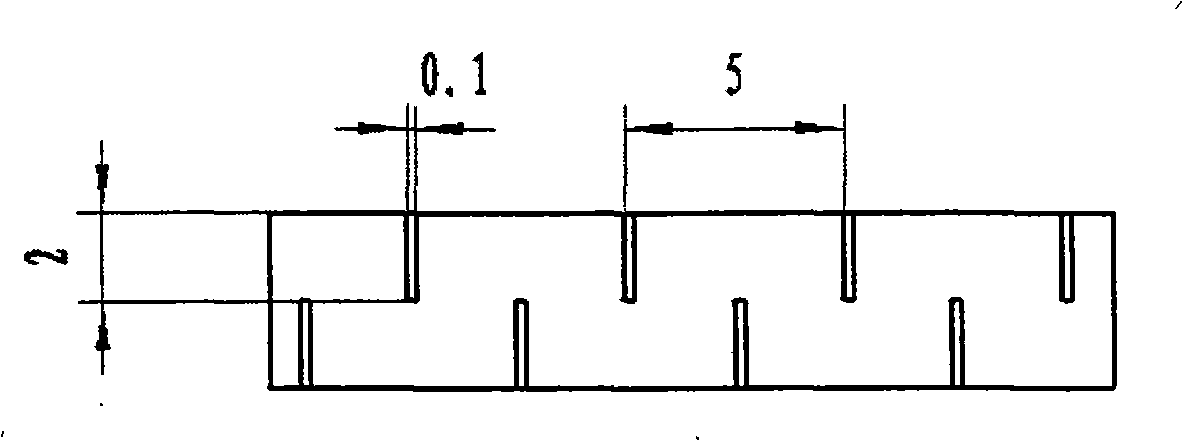

[0020] The oil and gas ring of the present invention is such as figure 2 As shown, the oil inlet holes and the air inlet holes are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com