Die-casting compound bottom kettle and manufacturing method thereof

A technology of double-bottomed pots and double-bottom sheets, which is applied to the special materials of cooking utensils, the structure of cooking utensils, cooking utensils, etc., can solve the problems of low heat fatigue resistance, affecting service life, and high production costs, and achieve heat fatigue resistance and stability High performance, extended service life, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings and examples.

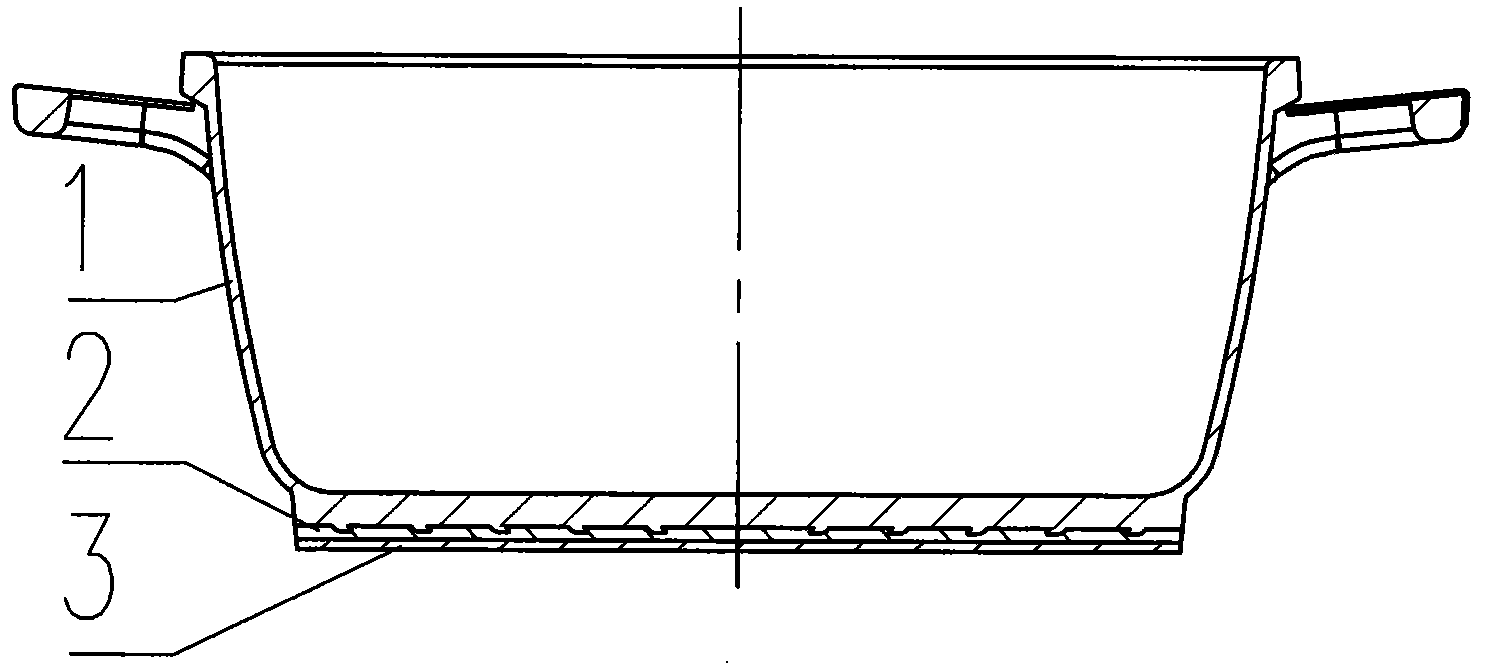

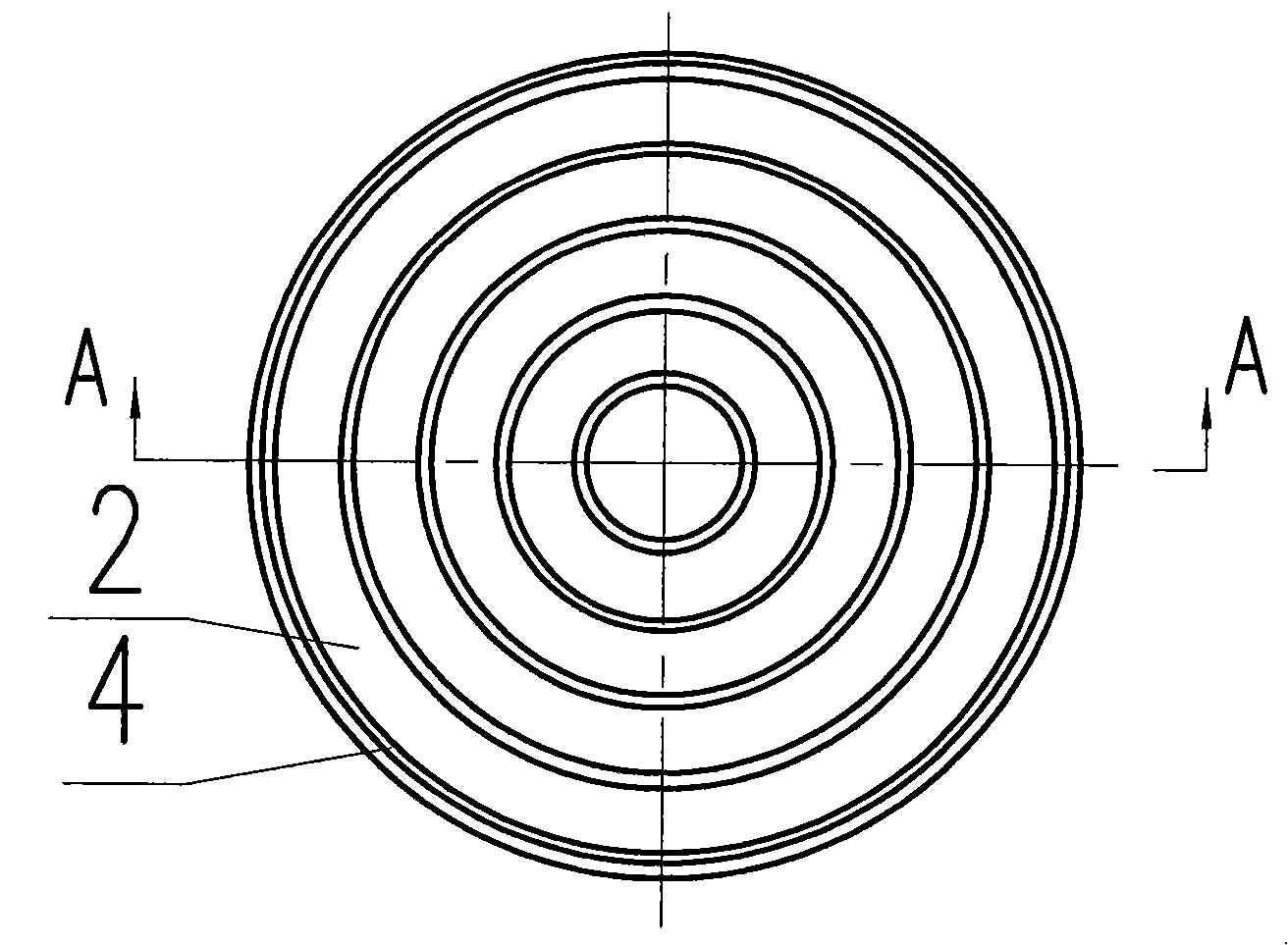

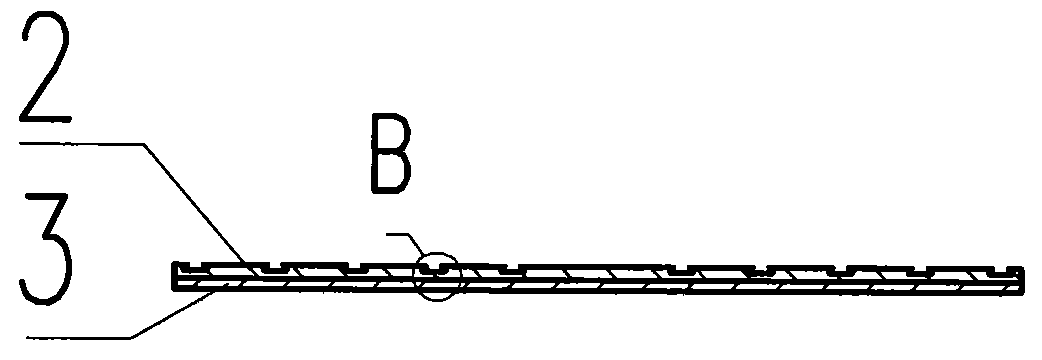

[0018] refer to Figure 1 to Figure 4 , the die-cast double-bottom pot includes an aluminum alloy pot body 1 and a double bottom sheet integrated with the lower part of the pot body by die-casting. Annular groove 4, both sides of the annular groove 4 are inner inclined side walls, in order to improve the thermal fatigue resistance stability of the die-casting pot, the composite material sheet 2 can be made of pure aluminum or aluminum alloy or other materials with a linear expansion coefficient close to that of aluminum alloy material. The above-mentioned die-casting double-bottom pot can be manufactured by the following process: First, make a double bottom: roll and compound the composite material sheet 2 and the stainless iron sheet 3 to form a double bottom, then punch the double bottom to shape, and then machine the ring-shaped concave on the double bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com