Power supply switch and control device for implementing nought power consumption standby

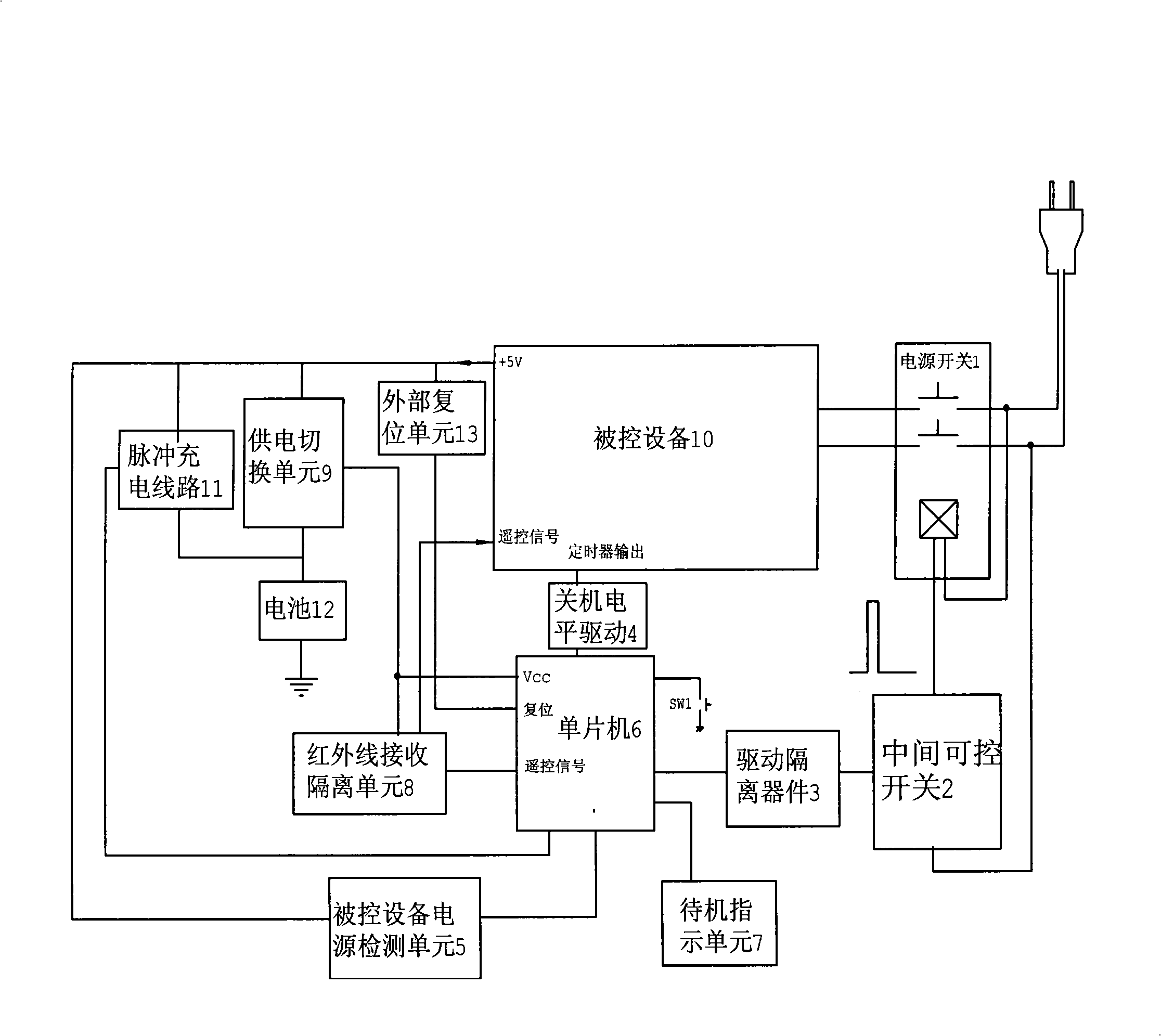

A technology of zero power consumption standby and power switch, which is applied to the power device inside the switch, electric switch, computer control, etc., can solve the problems of not being able to achieve intrinsic safety, not being able to start the machine, and high cost, and achieve simple structure and production process, Improved reliability, lifespan, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

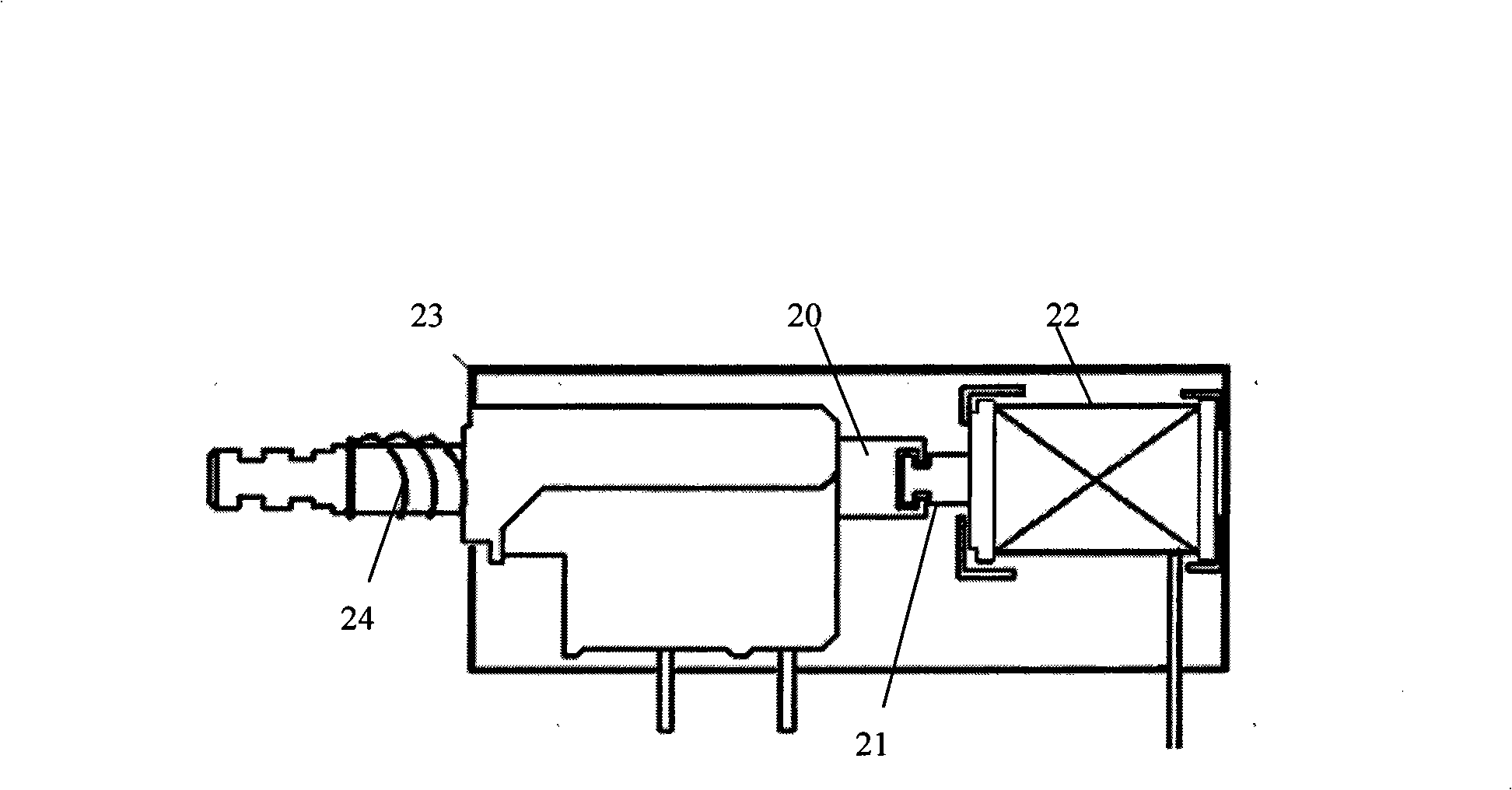

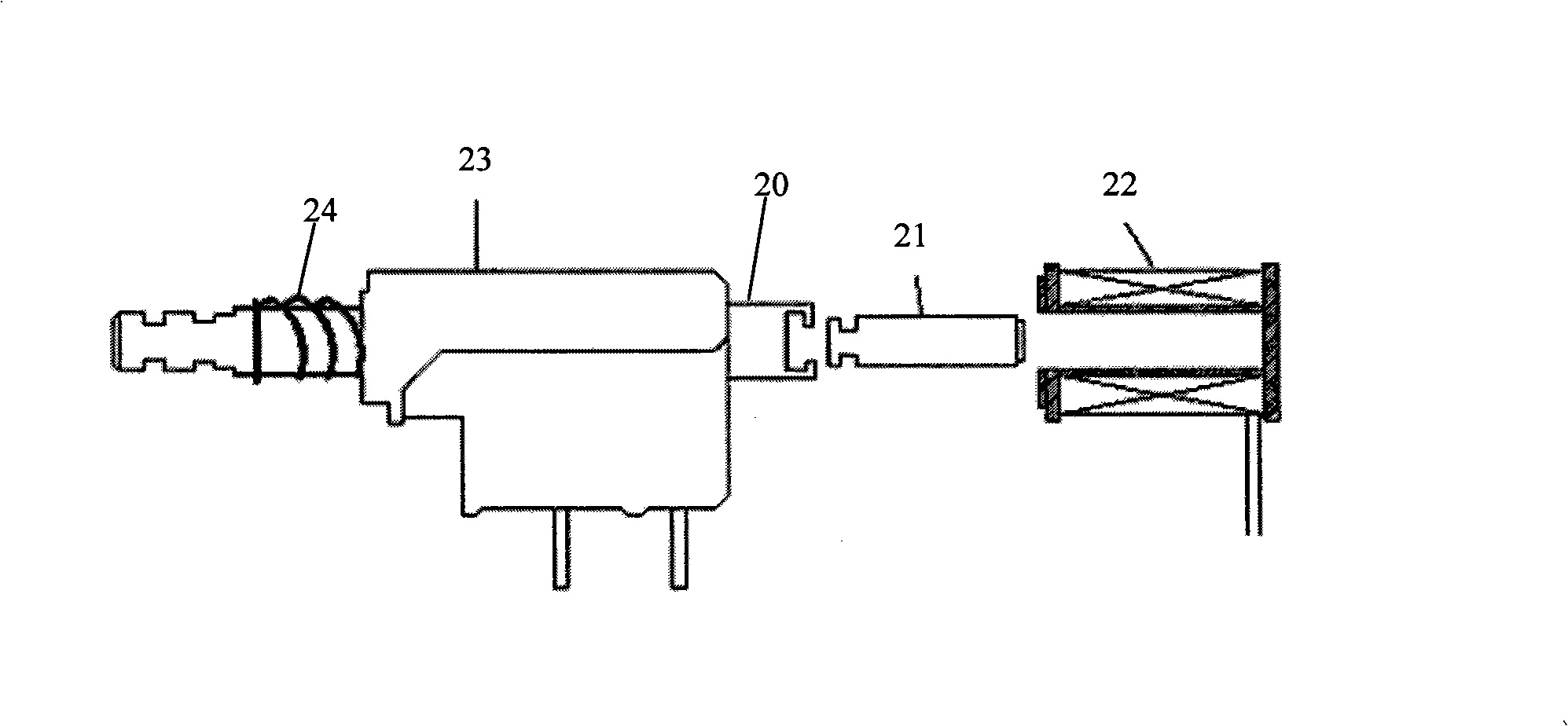

[0045] Such as Figure 1A and 1B As shown, the manual and pulse current control power switch of the present invention is improved on the basis of the general-purpose self-locking key power switch. A general-purpose push-button power switch generally consists of a push rod 20, a spring 24, a spring positioning piece, a switch contact, a self-locking guide rail, a self-locking shrapnel and a switch body 23. In the present invention, the tail of the push rod 20 of the existing general-purpose push-button power switch is lengthened so that it protrudes from the switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com