BOX-IN denoising technique for large-sized converter transformer

A converter transformer and transformer technology, applied in the direction of transformer/inductor noise damping, etc., can solve the problems of reduced strength, easy damage, and heavy disassembly and assembly workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A "BOX-IN" technical improvement and perfection

[0013] 1 "BOX-IN" front panel and top panel adopt sound insulation and sound absorption composite structure, which makes the structure simple and easy to install;

[0014] 2 The sound insulation and sound absorption board adopts self-supporting structure, and the internal design has a skeleton, which can enhance the strength of the board;

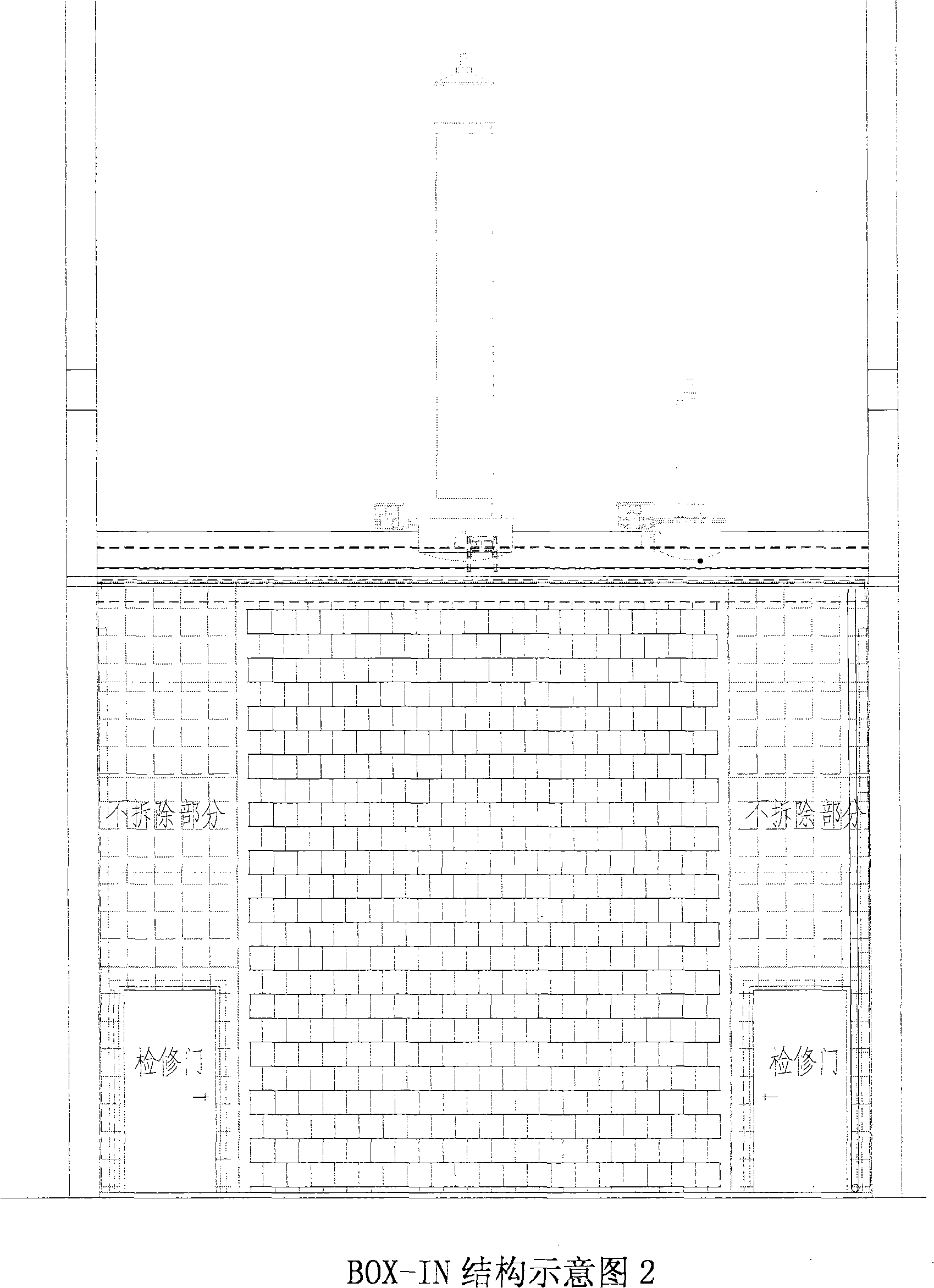

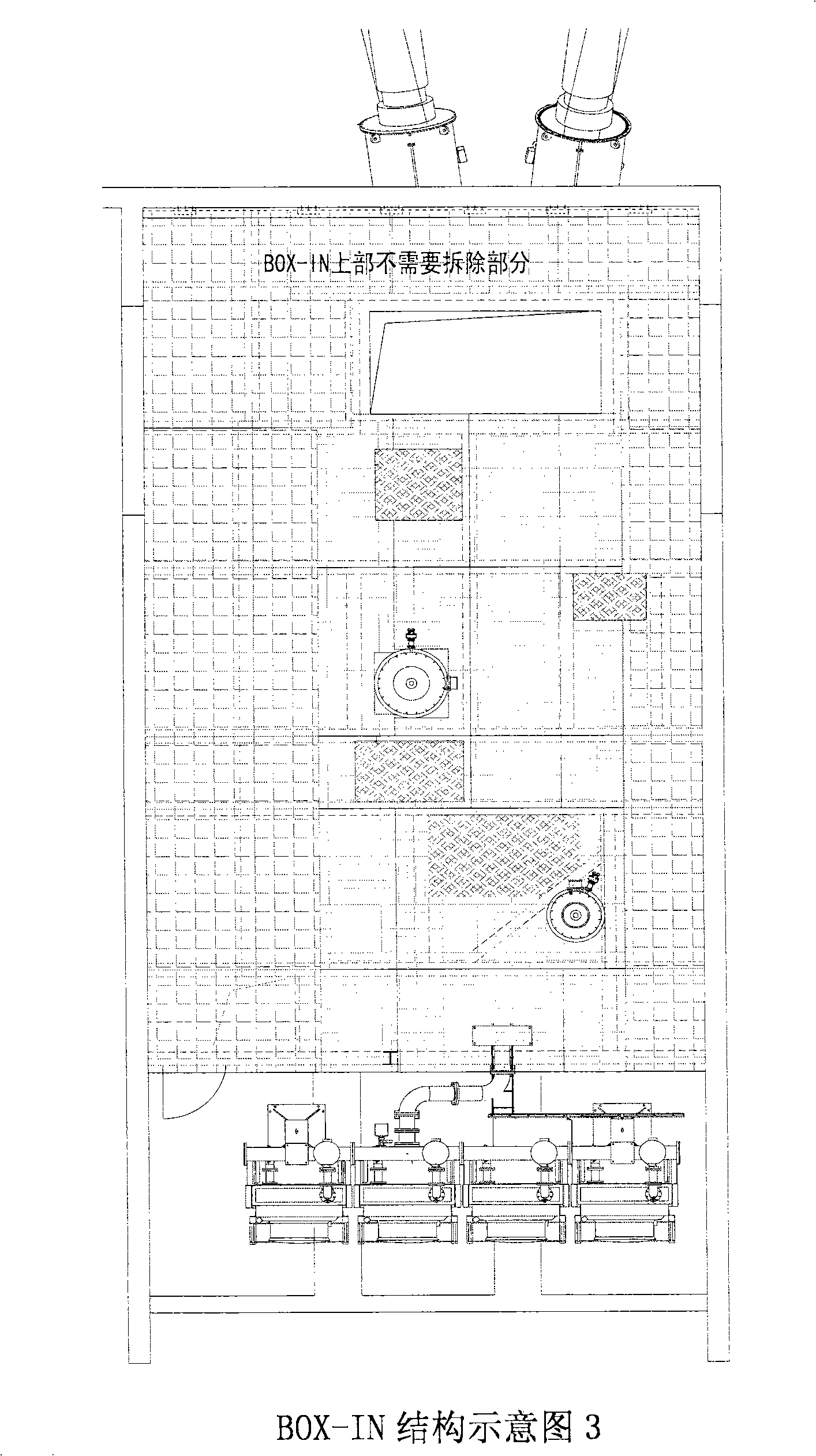

[0015] 3 All sound insulation and sound-absorbing panels are shaped and manufactured, without on-site cutting and processing, and the reuse rate is high;

[0016] 4 Under the condition of not affecting the movement of the transformer, the "BOX-IN" structure has been optimized, and part of the sound insulation, sound-absorbing panels and steel frames do not need to be disassembled, which reduces the workload during maintenance;

[0017] 5 The "BOX-IN" node is designed as a bolt connection, which can be disassembled quickly without loosening or falling off, avoiding potential safety ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com