Constant torque load application soft start-up test method

A test method and soft-start technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve problems such as complex structure, hidden dangers, safety problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

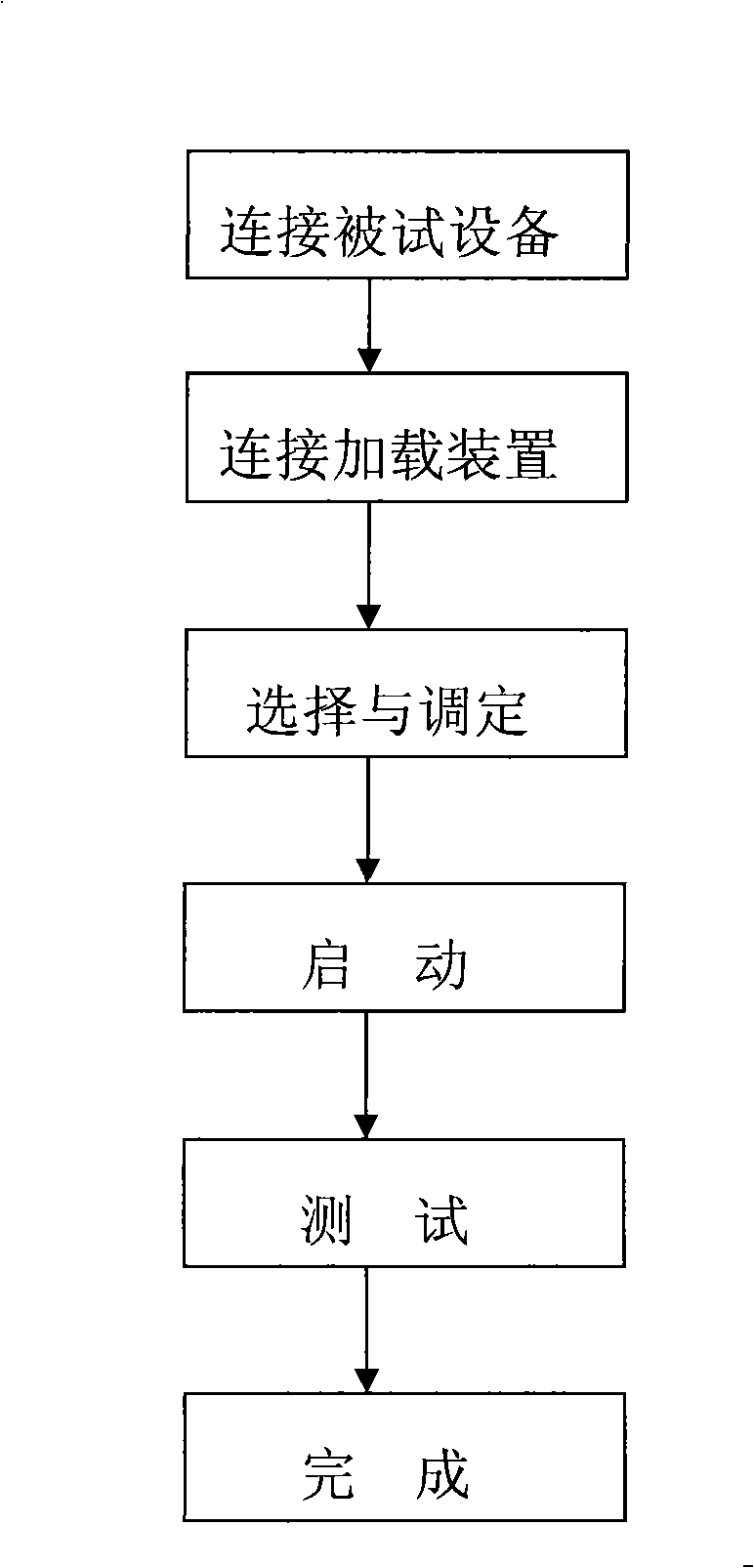

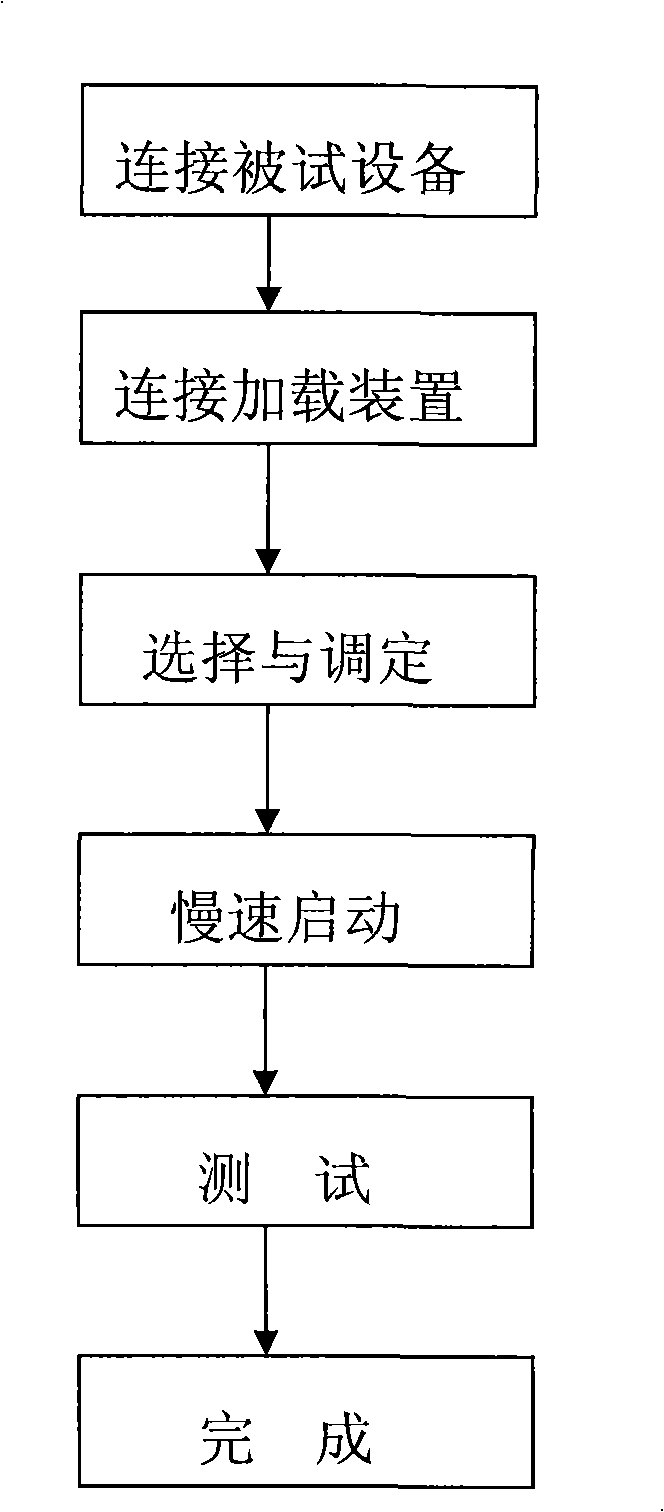

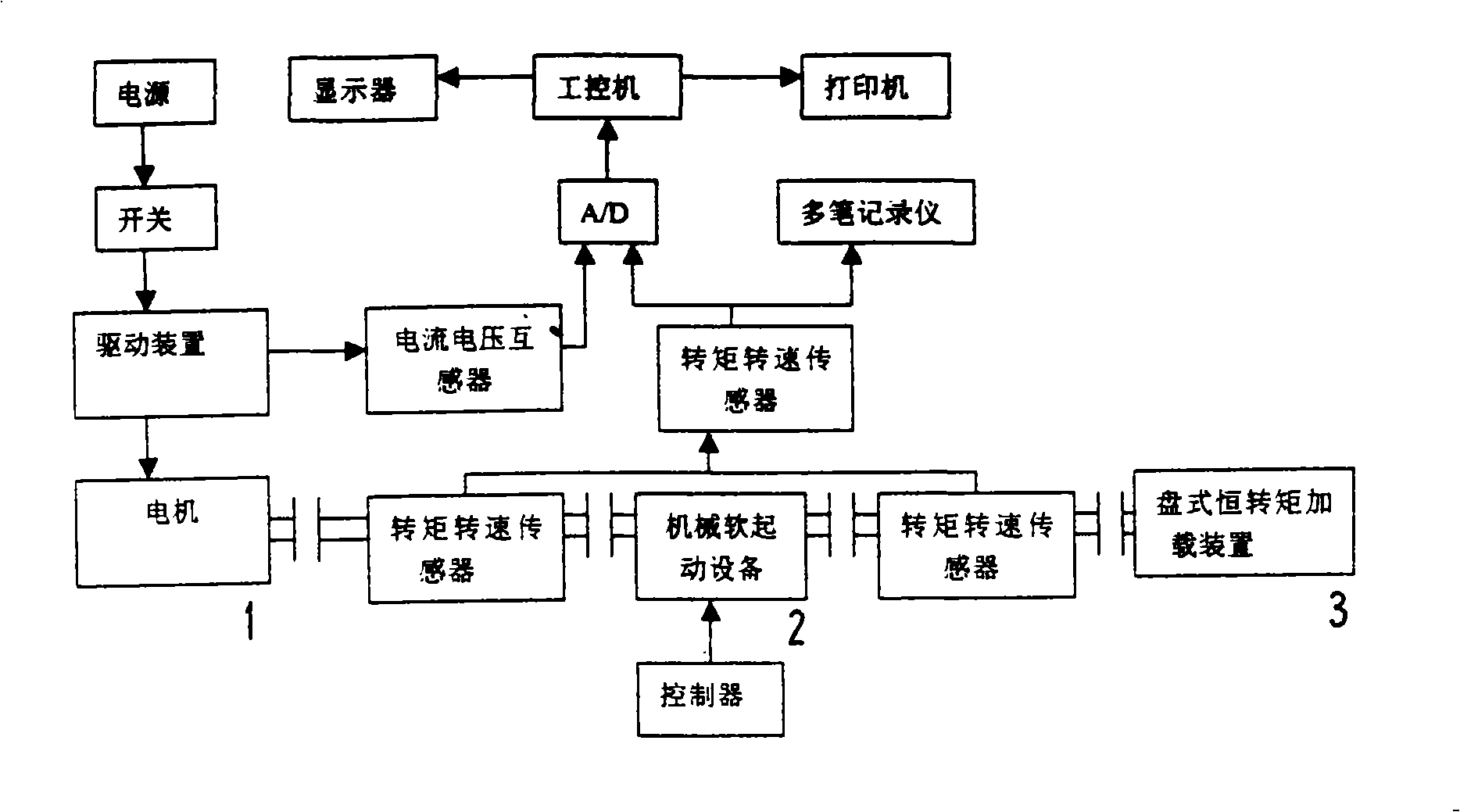

[0023] refer to figure 1 , 3 , constant torque loading soft start test method, the method is in image 3 It is carried out on the test device shown, and the tested equipment is mechanical soft start equipment 2, and the corresponding test steps are as follows:

[0024] 1. Connect the device under test - on the test bench, drive and connect the mechanical soft start device 2 (such as an adjustable hydraulic coupling, etc.) Torque speed sensor;

[0025] 2. Connecting the loading device—the disk-type constant torque loading device 3 and the mechanical soft start device 2 are connected by drive, and another torque speed sensor is arranged on the drive shaft;

[0026] The above-mentioned two torque speed sensors are respectively connected to the recorder, printer, and display in the test system;

[0027] The above-mentioned disc type constant torque loading device 3 includes elastic elements, brake brakes, brake arms, brake connecting rods, brake discs and friction plates, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com