Double-cylinder compressor in refrigerating device

A technology for refrigeration equipment and compressors, applied in the field of compressors, can solve problems such as increasing wear, reducing compressor performance, and refrigerant leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

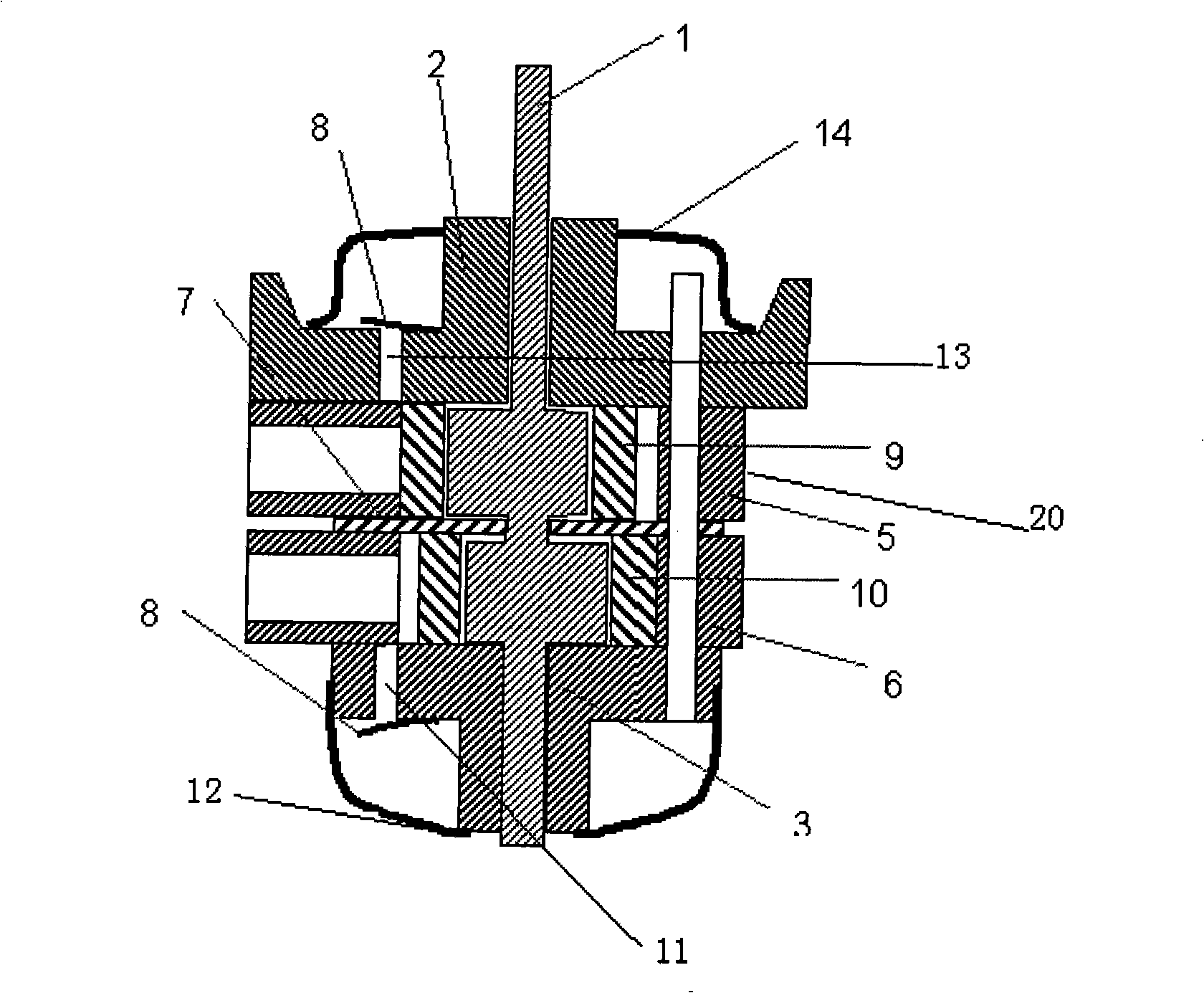

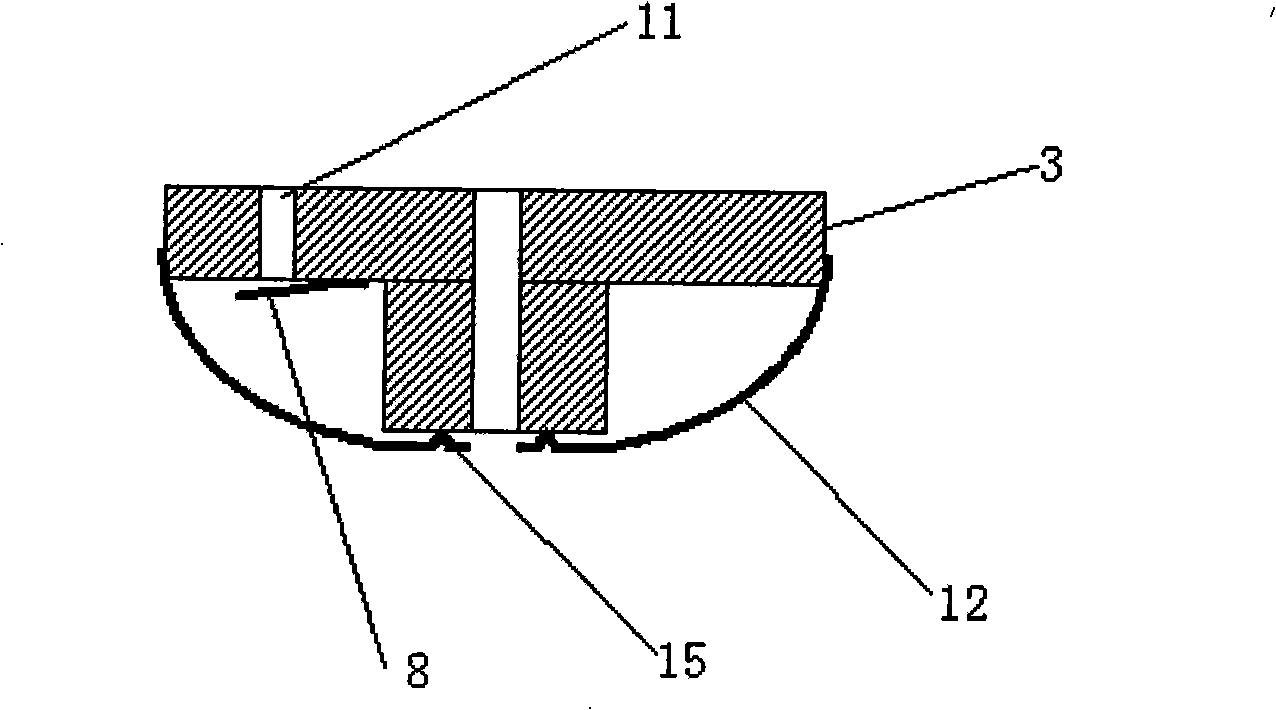

[0030] refer to figure 1 , most of the compressor body 20 is still manufactured using the prior art, that is, the two ends of the crankshaft 1 are respectively installed on the upper bearing 2 and the lower bearing 3 inside the compressor body 20; two eccentric structures in the middle of the crankshaft 1 Set the upper roller ring 9 and the lower roller ring 10 respectively, the upper roller ring 9 and the lower roller ring 10 are respectively located in the upper cylinder 5 and the lower cylinder 6, and the upper cylinder 5 and the lower cylinder 6 are separated by a middle partition 7 open. The upper bearing 2 is provided with an upper exhaust port 13, which is covered with an exhaust valve plate 8, and the upper muffler 14 is installed on the upper bearing 2.

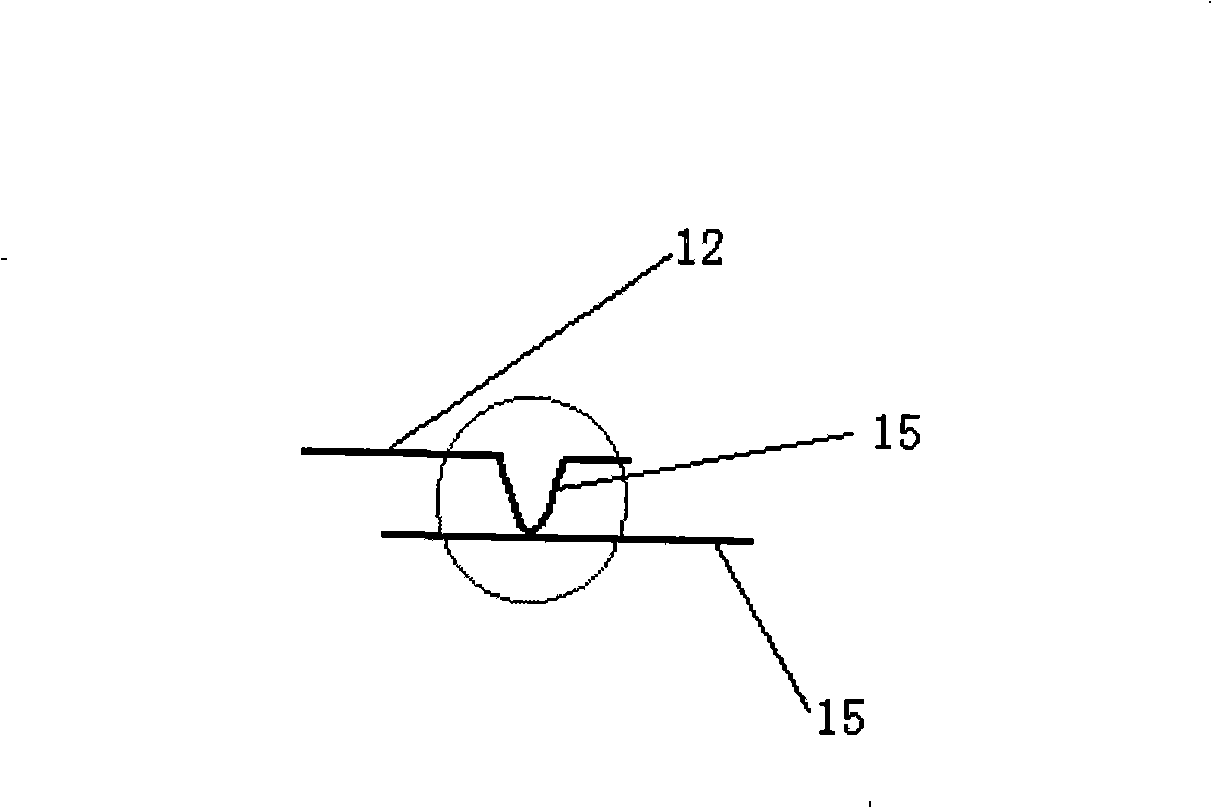

[0031] refer to Figure 4 ,, according to the technical solution of the present invention, the inner corner 25 of the center hole of the lower muffler 22 should be processed into a slope, and correspondingly, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com