Rapid parking method of methanol to olefins reaction-regeneration system

A methanol-to-olefin and regeneration system technology, which is applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, molecular sieve catalysts, etc. The effect of short time, weakening influence, and avoiding prolonged contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

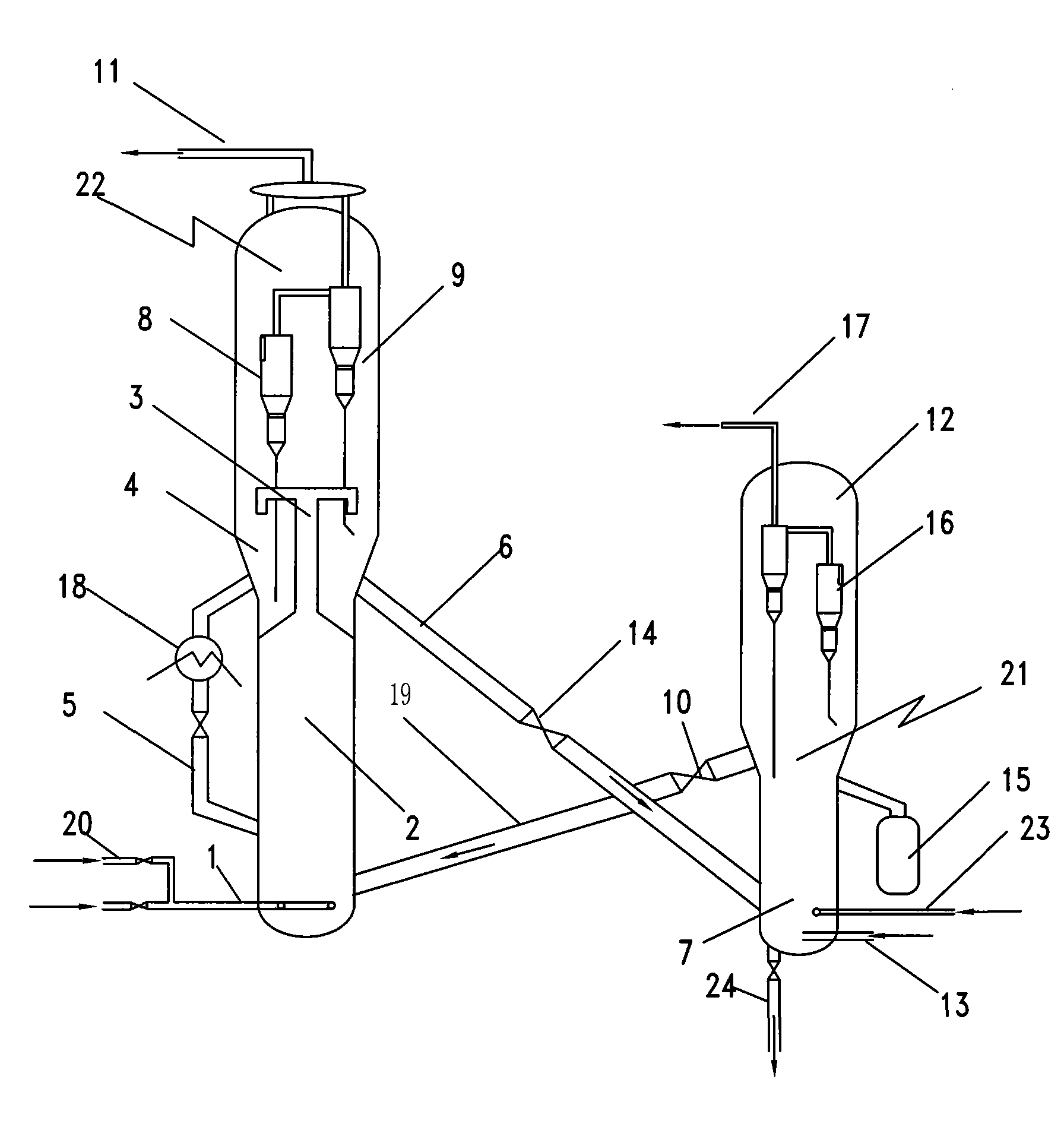

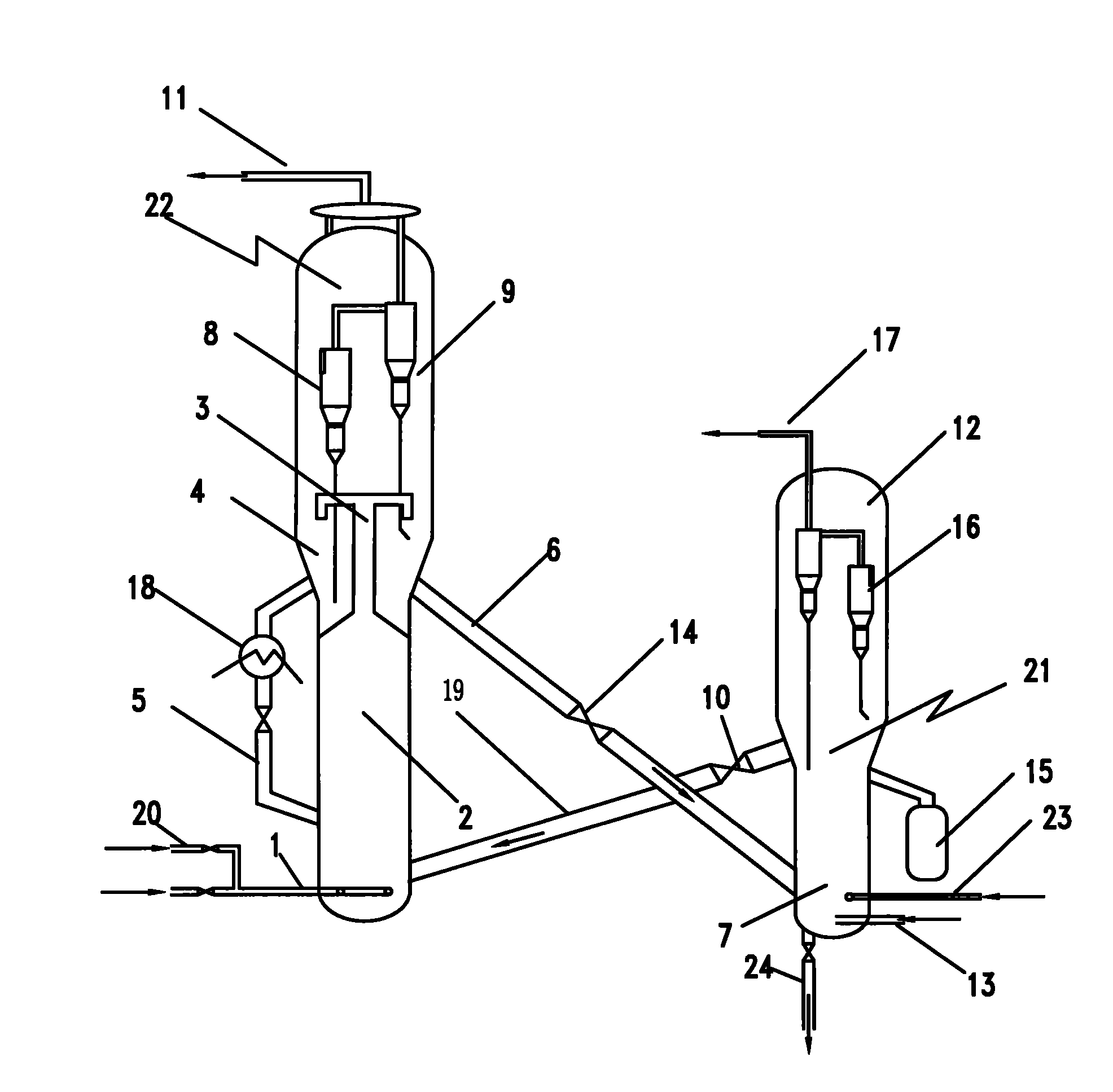

[0017] Such as figure 1 In the methanol-to-olefins reaction-regeneration system shown, the reactor is a fast bed, the regenerator is a bubbling bed, the catalyst is SAPO-34 molecular sieve, and the feed rate of methanol is 4 tons / hour. The feed flow / time speed is gradually cut out of the reactor within 1 hour, that is, the amount of methanol feed is reduced by 1 ton each time, and each time interval is 15 minutes. At the same time or after the raw material is cut out of the reactor, medium-pressure steam at 275°C is cut into the reaction system, and the amount of steam cut in is 50% of the amount of raw material cut out, that is, 1 ton of methanol is not cut out, and 0.5 ton is supplemented water vapor. Slightly increase the circulation volume of the catalyst to ensure the normal circulation of the catalyst in the reaction-regeneration system, continue to pass regeneration air into the regenerator, and control the temperature of the regenerator at about 680°C. While maintaini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com