Method for making mini optical fibre spectrometer narrow slit

A fiber optic spectrometer and a manufacturing method technology, which are applied in the fields of spectrum investigation, microstructure technology, microstructure device, etc., can solve the problems of inapplicability to micro-miniature fiber optic spectrometers, poor interface versatility, mechanical slits, multiple diffractions and low resolution, etc. , to achieve the effect of eliminating secondary diffraction, firm fixation, and simple spatial structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

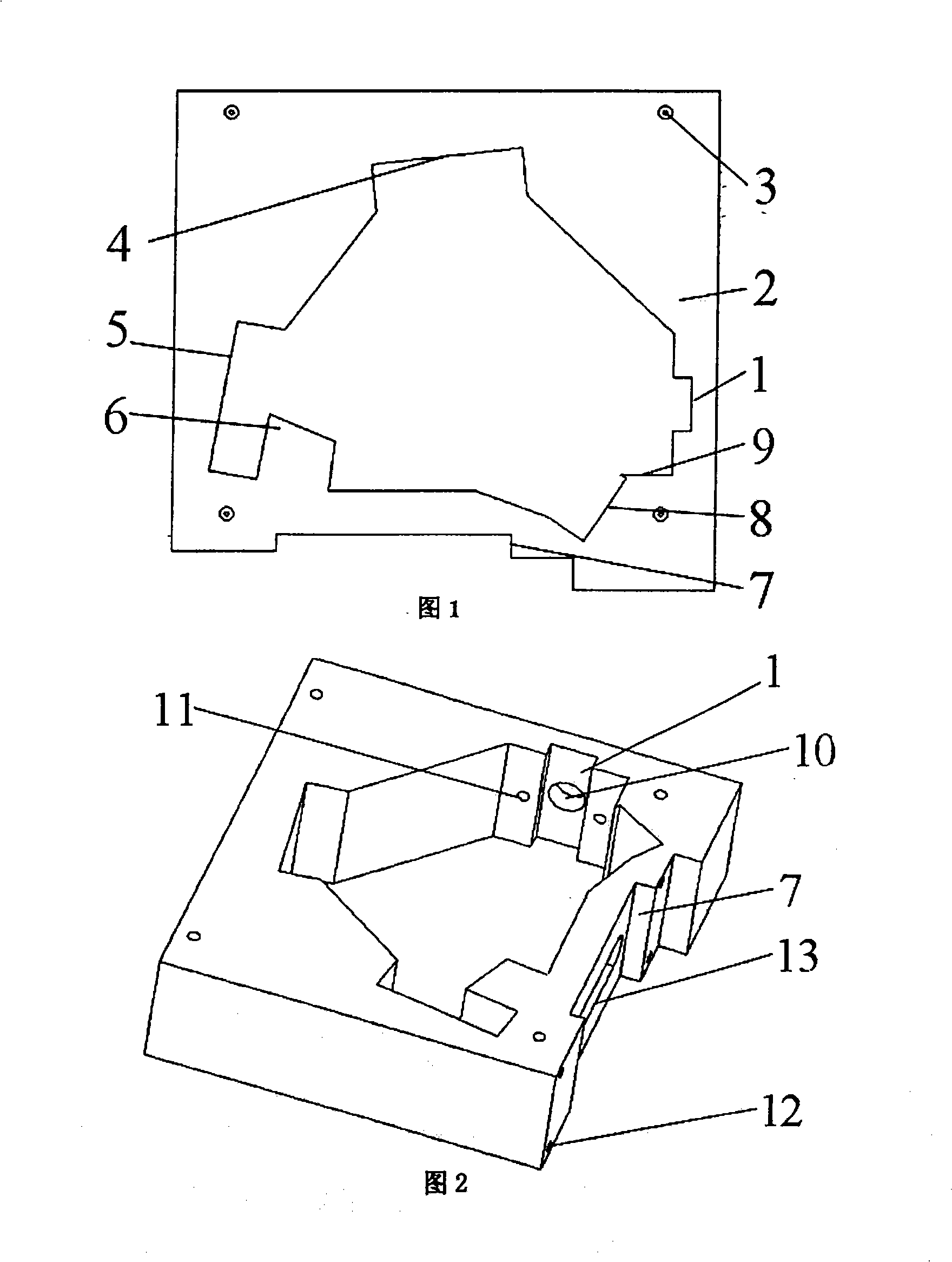

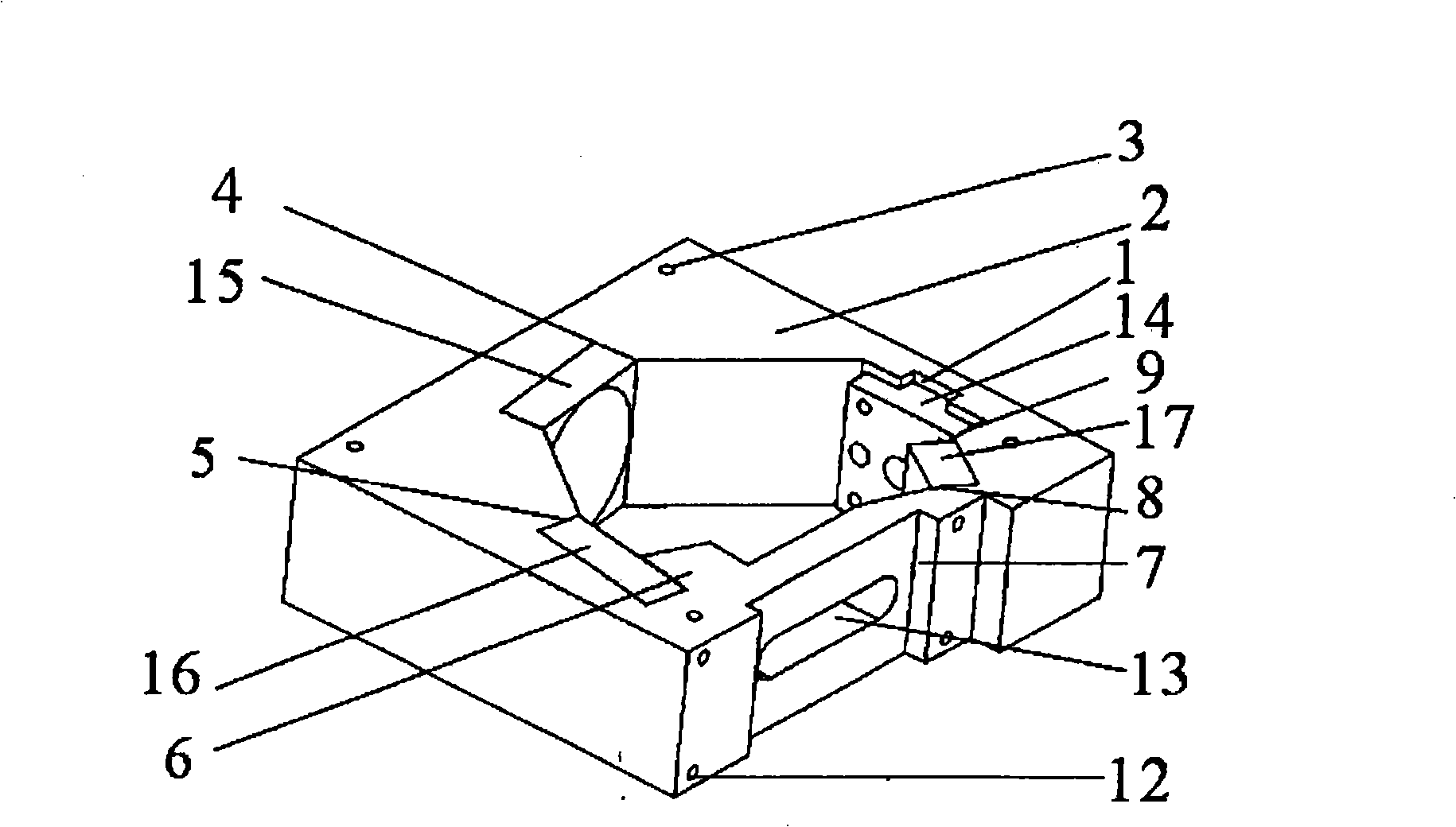

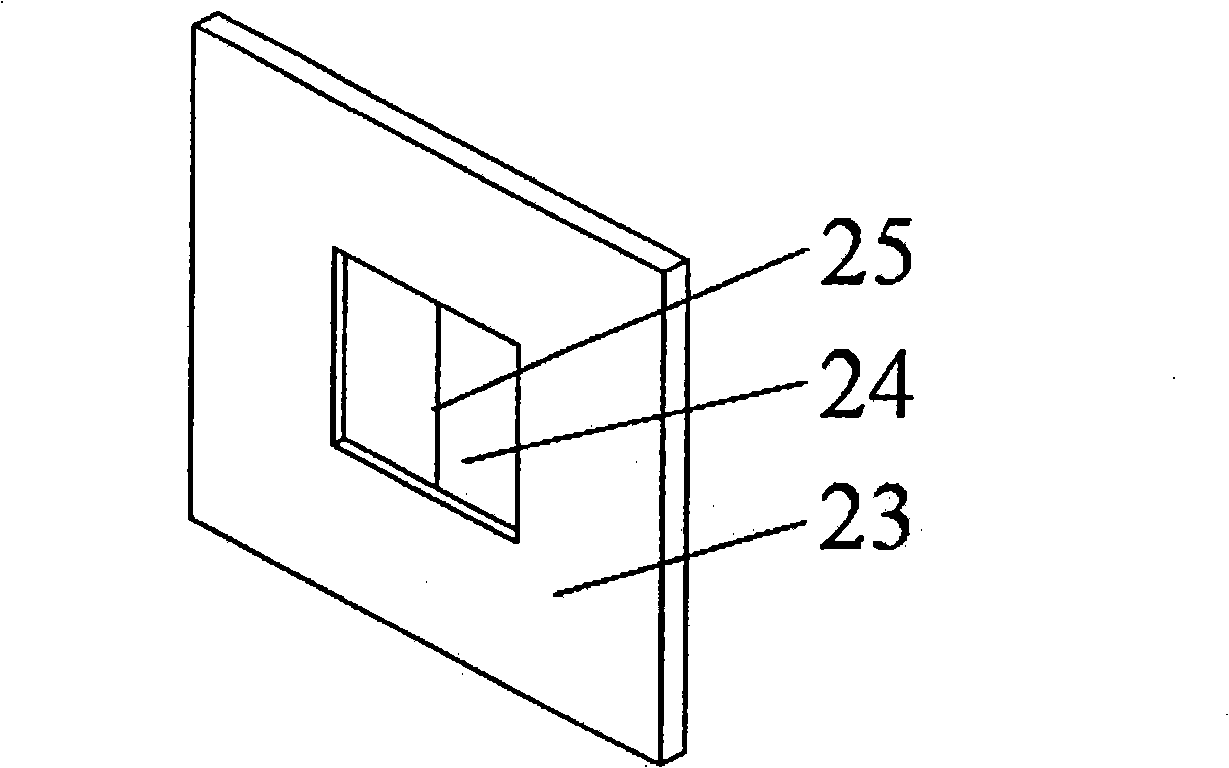

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments. The present invention miniature optical fiber spectrometer support and related components are as accompanying drawing 1, Fig. 2, image 3 , Figure 4 , Figure 5 , Image 6 As shown, it includes installation slot 1, bracket 2, first threaded hole 3, first slot 4, second slot 5, aperture 6, third slot 7, fourth slot 8, stepped surface 9, entrance 10, second slot Screw hole 11, third screw hole 12, outlet 13, gland 14, imaging mirror 15, collimating mirror 16, grating 17, slit 23.

[0027] The bracket 2 is made of metal material and is made by high-precision wire cutting. The width and depth of the installation groove 1, the first groove 4, the second groove 5, the third groove 7 and the fourth groove 8 on the support 2 body can be determined according to the mounting surface of the optical e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com