Method for producing perforating net surface facing material of infrared negative ion health-care sanitary napkins

A manufacturing method, infrared technology, is applied in the manufacturing of health care products and the manufacture of perforated mesh fabrics for infrared negative ion health care sanitary napkins. The effect of immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

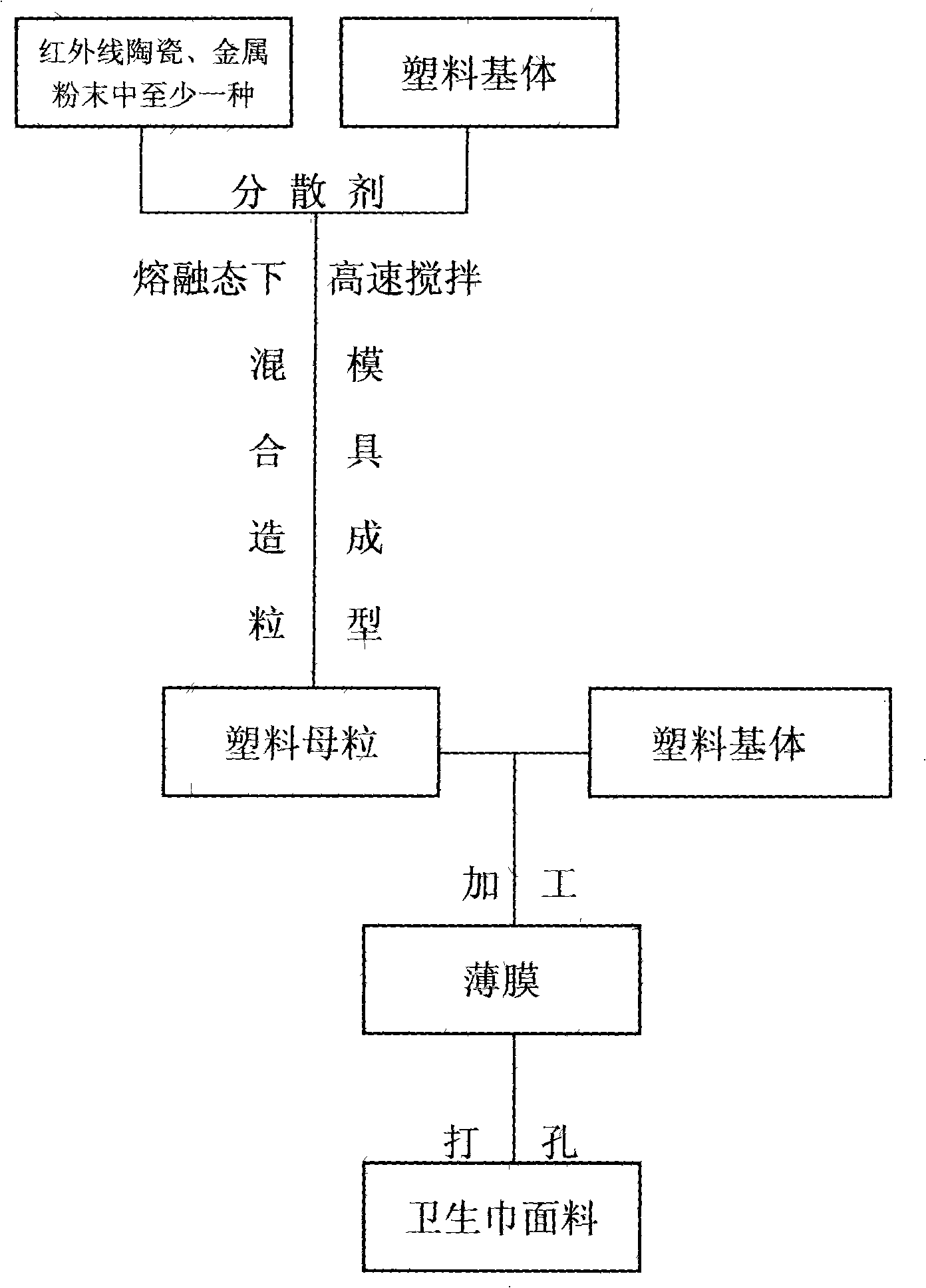

Method used

Image

Examples

Embodiment 1

[0026] Mix 0.3kg of high-temperature dry-activated infrared ceramic powder with 99.7kg of plastic matrix PE, heat the mixture to melt, add dispersant polymer wax, use a high-speed mixer, and make 100kg of plastic masterbatch through the corresponding mold after fully stirring; Mix the above-mentioned plastic masterbatch and the PE component of the plastic matrix at a ratio of 20%:80%, process it into a film at 200°C to 300°C in a hot-melt state, and then uniformly open pores on the film to reduce the cost of infrared negative ion health care. Sanitary napkin perforated mesh fabric, the number of negative ions produced by this fabric reaches 5000 / cm 3 Around 80% emissivity of infrared rays.

Embodiment 2

[0028] Repeat the same steps as described in Example 1, but the contents of the infrared ceramic powder and the plastic matrix PE are respectively 3kg and 97kg in the process of manufacturing the plastic masterbatch. The number of negative ions produced by the fabric produced by this process reaches 5600 / cm 3 Around 85% emissivity of infrared rays.

Embodiment 3

[0030] Repeat the same steps as described in Example 1, but the contents of infrared ceramic powder and plastic matrix PE are respectively 5kg and 95kg in the process of manufacturing plastic masterbatch. The number of negative ions produced by the fabric produced by this process reaches 6000 / cm 3 Around 87% emissivity of infrared rays.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com