Long-acting type oil smoke purification system technique

A kind of oil fume purification and technical technology, applied in the field of environmental protection, can solve the problems of oil fume exhaust gas solidification, loss, and inability to remove by itself

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

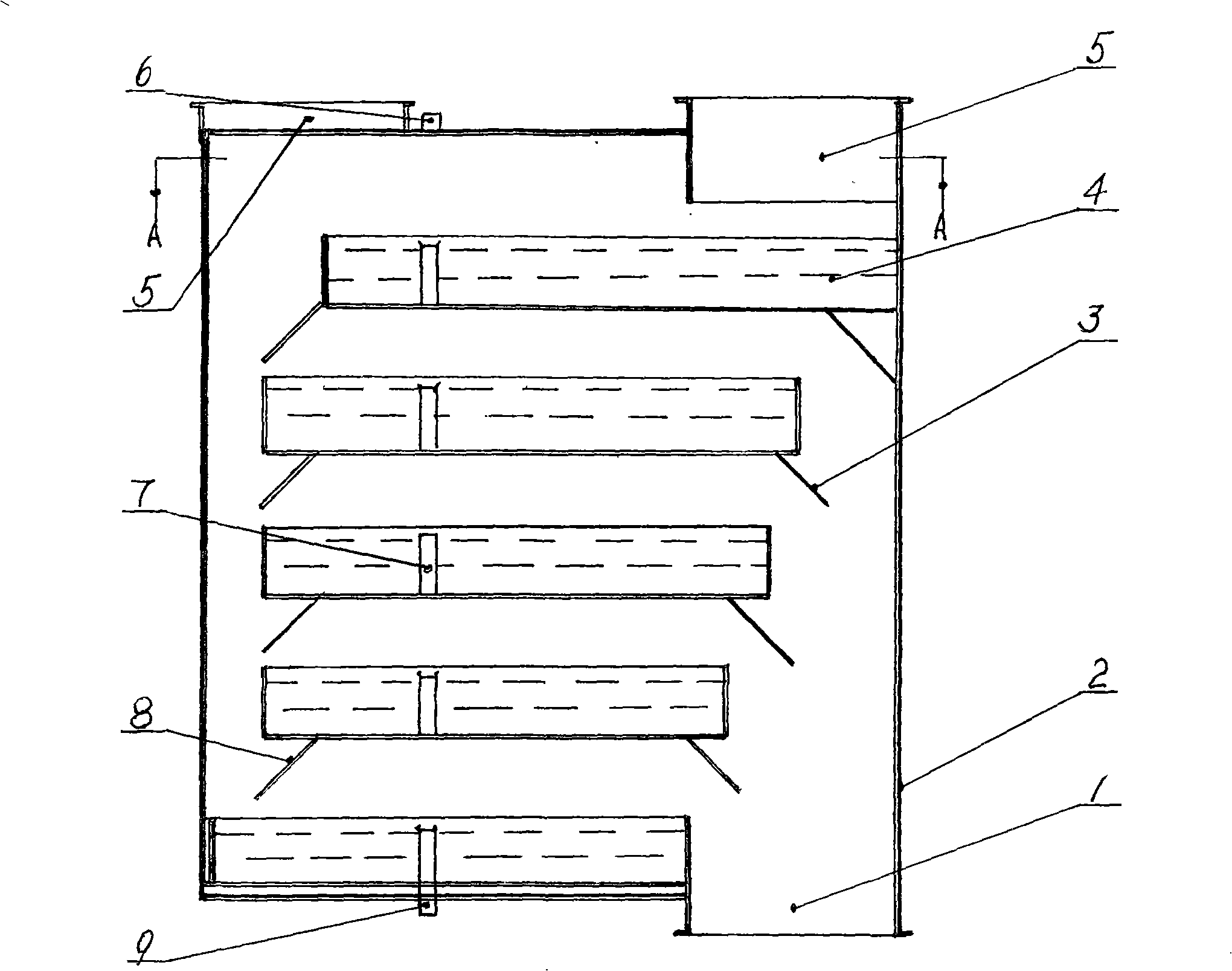

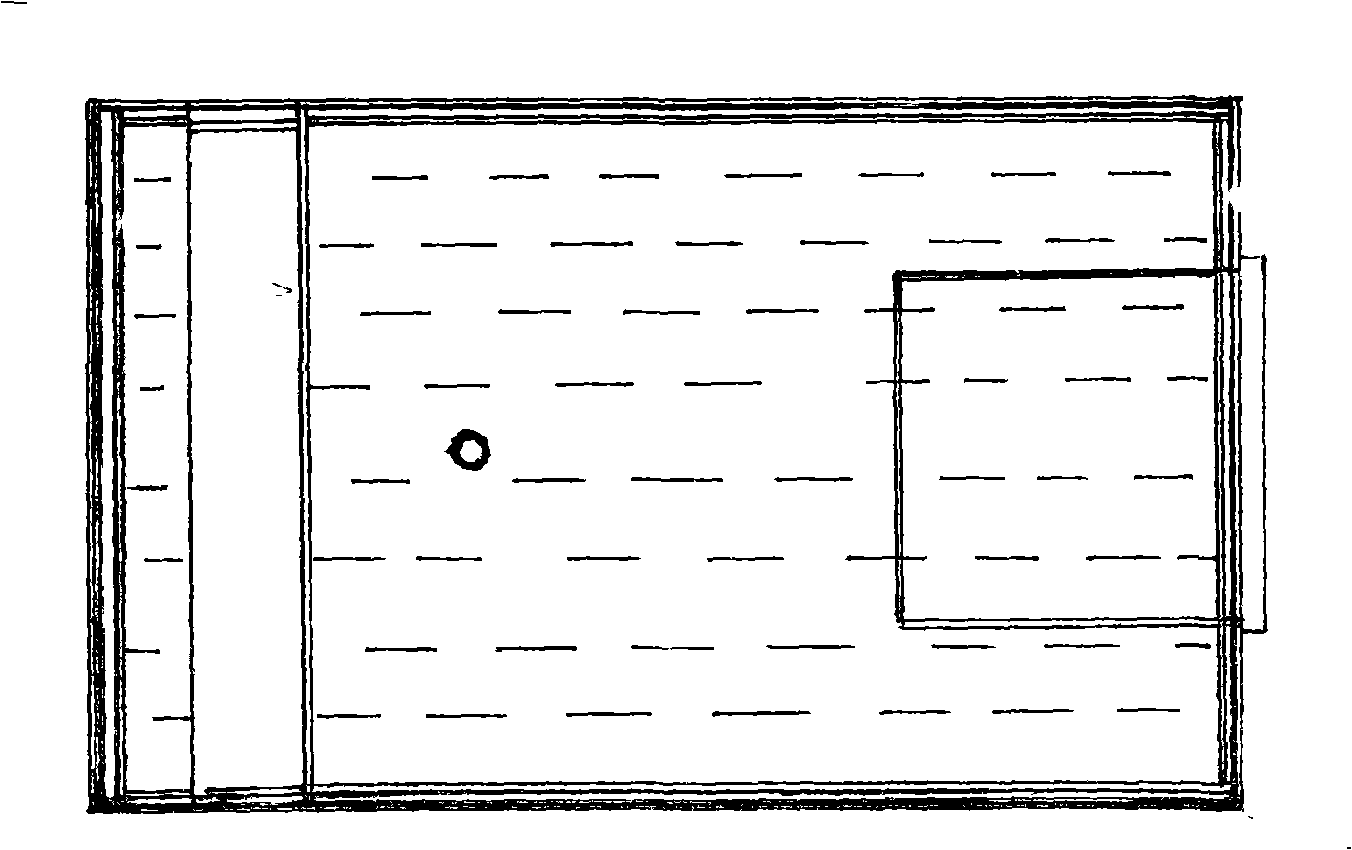

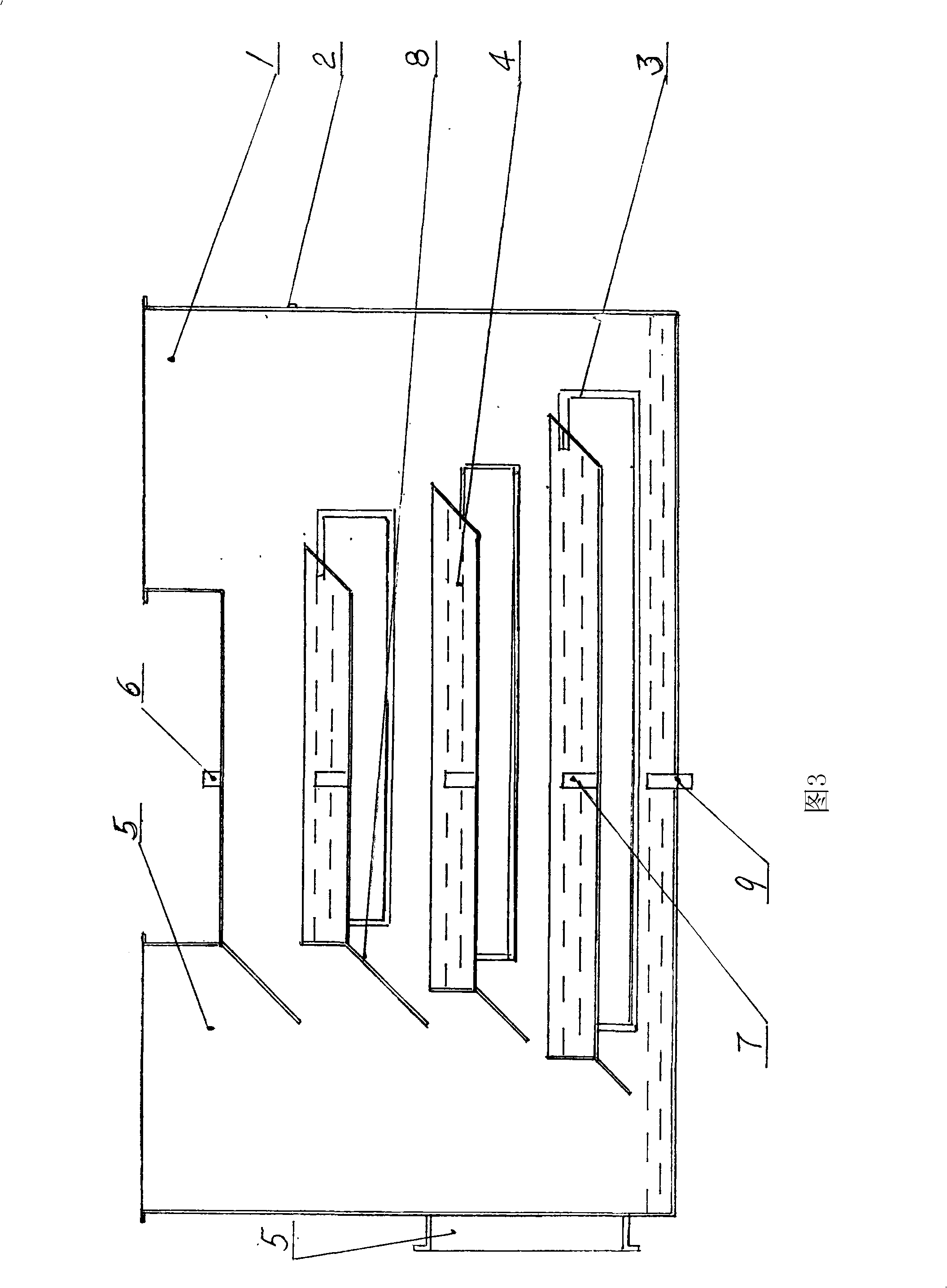

[0011] Specific implementation plan: the main body 2 of this technology is made of thin steel plates into a rectangular cylinder, the size of each part of which is determined according to the air volume of the oil fume exhaust gas per hour, and the two ends of the main body 2 are respectively welded or riveted with steel plates Made into a circular or rectangular connecting flange, one side of the flange is used as the oil fume exhaust gas inlet 1, and the other side flange is used as the oil fume exhaust gas outlet 5. Several guide plates 3 at the front and some guide plates 8 at the rear of the main body 2 are also made of thin steel plates or galvanized steel plates, and are fixed at the positions shown in the figures. The several adsorption containers 4 that are established in the main body 2 are also folded into thin steel sheets or galvanized steel sheets or after being stretched and calendered with a mold, and are fixed on the inwall of the main body 2 with screws accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com