Horizontal type smelting furnace

A smelting furnace and horizontal technology, applied in the field of horizontal smelting furnaces, can solve problems such as heat transfer, poor mass transfer conditions, smoke escaping to pollute the environment, difficulty in discharging materials from the smelting furnace, etc., and achieve easy control and high smelting quality , The effect of simple discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

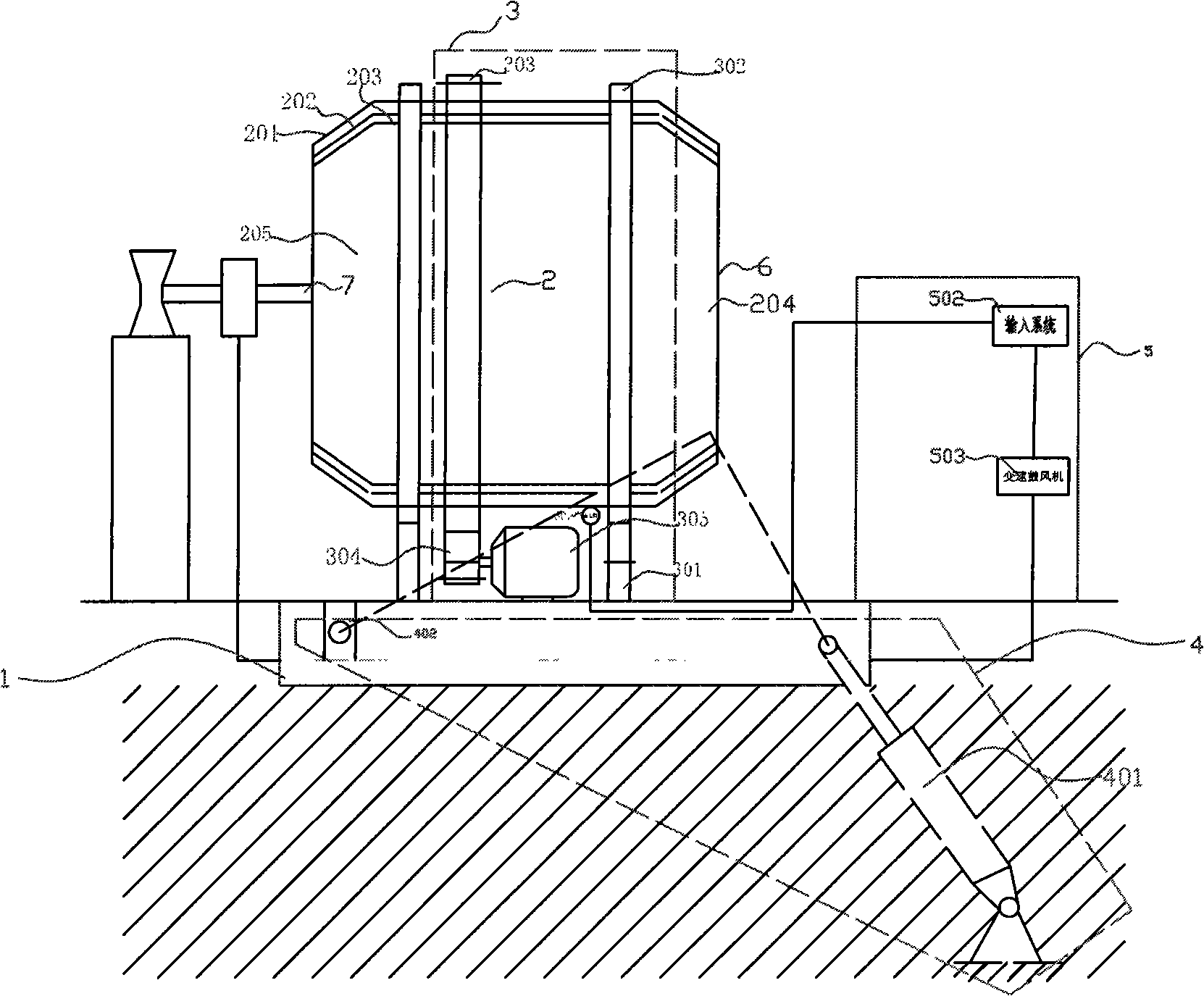

[0030] see figure 1 , a horizontal melting furnace, comprising a furnace body bracket 1 and a furnace body 2, the furnace body 2 is provided with a shell 201, a heat insulating layer 202 and a refractory layer 203 in sequence from the outside to the inside, the furnace tail 204 of the furnace body 2 and the The flue 6 is connected, the furnace head 205 of the furnace body 2 is connected with the pulverized coal inlet 7, and the furnace body 2 is horizontally arranged above the furnace body bracket 1; the horizontal melting furnace also includes a rotating mechanism 3 and a tilting mechanism 4, and the rotating mechanism 3 Set between the furnace body bracket 1 and the furnace body 2, the rotating mechanism 3 includes a support ring 302, a ring gear 303, a gear 304 and a reducer 305; the supporting wheel 301 is arranged at the bottom of the furnace body 2, and the support ring 302 is arranged On the body 2, the supporting ring 302 is matched with the supporting wheel 301, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com