Oil smoke automatic decomposition type nanometer fume exhauster

An automatic decomposition and range hood technology, applied in the field of cabinets, can solve the problems of eliminating oil fume pollution and failing to make breakthroughs in technical performance, and achieves the effects of simple structure, long service life and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

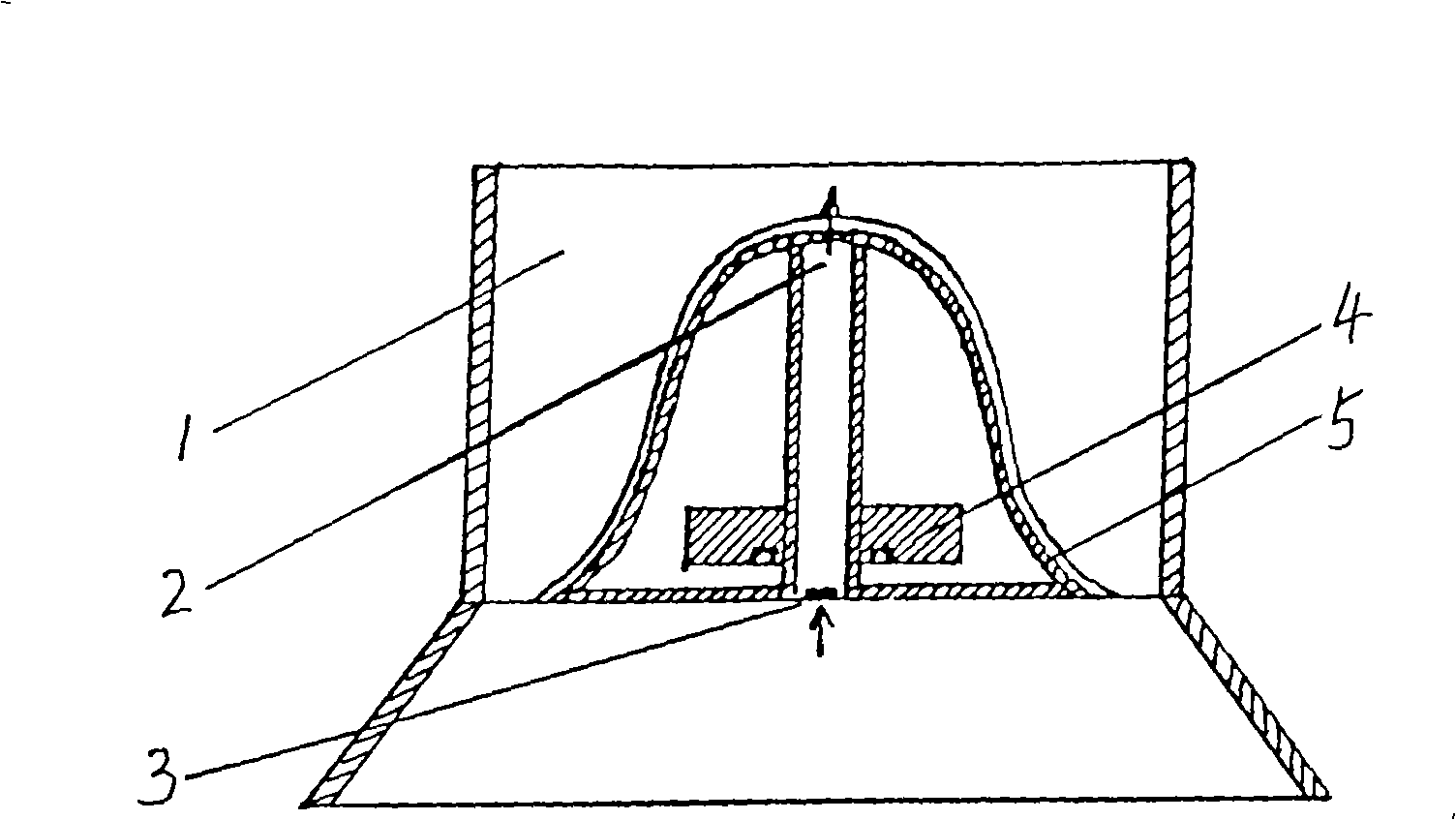

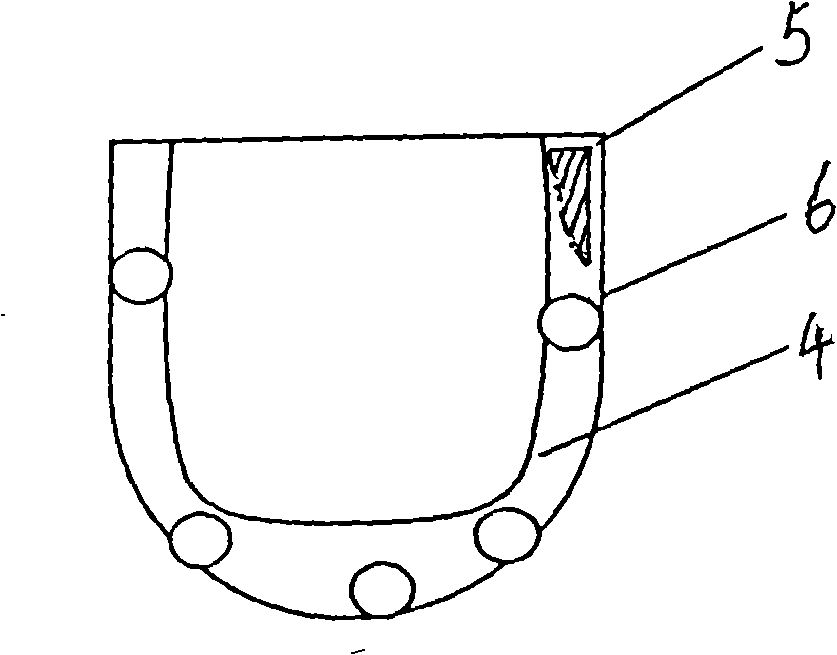

[0017] refer to Figure 1~3 , The housing 1 and the flue 2 of the following embodiments of the automatic decomposing range hood of the present invention are made of stainless steel plates with a thickness of 2mm, and the inner diameter of the housing 1 is ¢1.2m. The inner diameter of the flue 2 is ¢0.2m, and the flue 2 is arranged in the center of the inner cavity of the shell 1 upwards and coaxially. The inner diameter of the activated carbon ring 4 matches the outer diameter of the flue 2, and the activated carbon ring 4 is socketed on the flue 2; the outer diameter of the activated carbon column 3 matches the inner diameter of the flue 2, and the activated carbon column 3 is coaxial The line is set in the smoke inlet at the lower end of the flue 2. The activated carbon ring 4 and the activated carbon cylinder 3 are provided with a plurality of holes 6 with an inner diameter of ¢2 mm in a honeycomb shape in the radial direction. The surfaces of the activated carbon ring bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com