Silo bottom rectifying energy dissipator

An energy dissipator and shaft technology, which is applied in waterway systems, climate change adaptation, sewage removal, etc., can solve the problems of difficulty in ensuring ventilation effects, large fluctuations in the surface of the water flow, and high impact pressure on the bottom plate, saving ventilation facilities and having a simple structure. , the effect of smooth flow transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

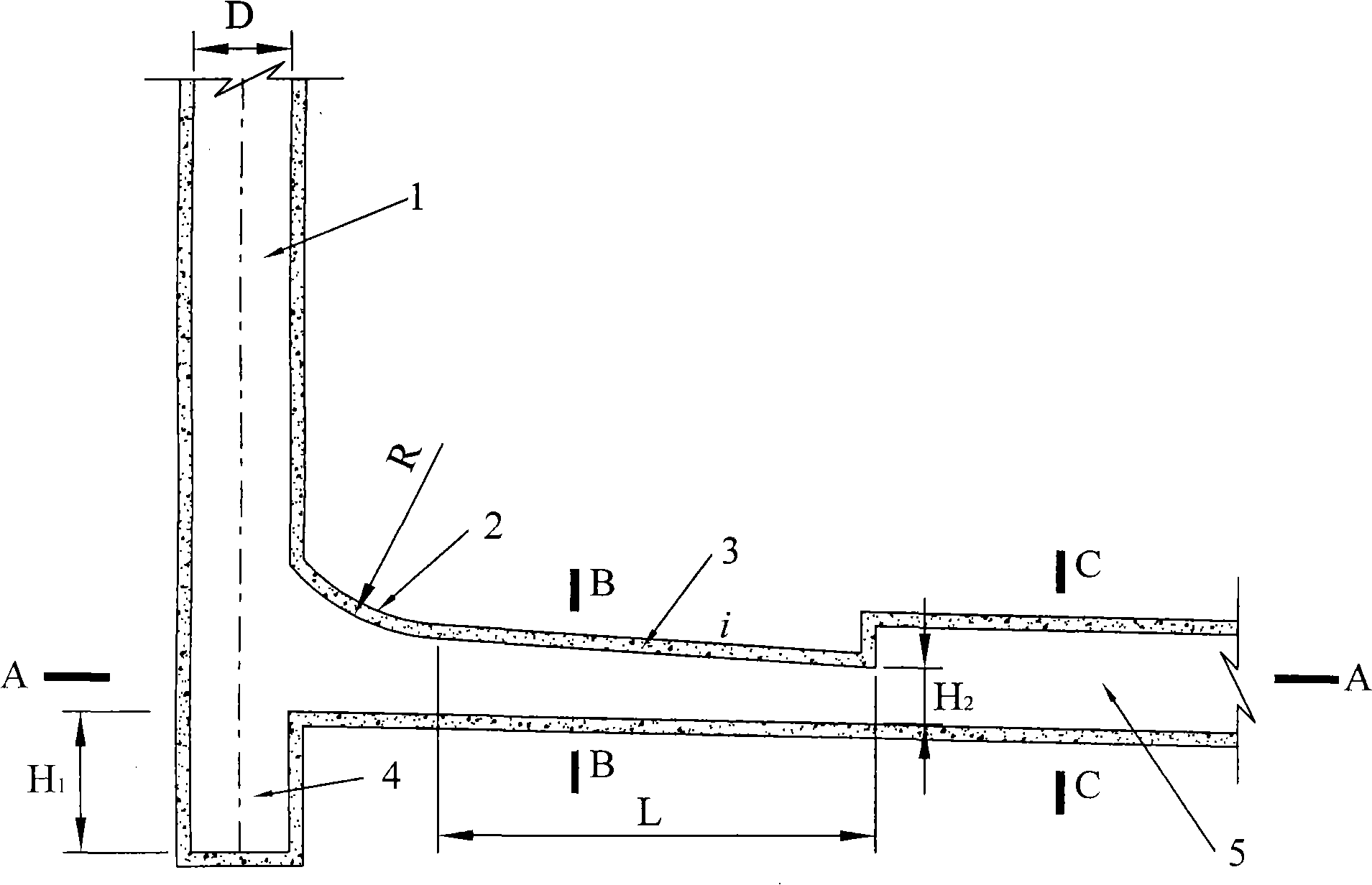

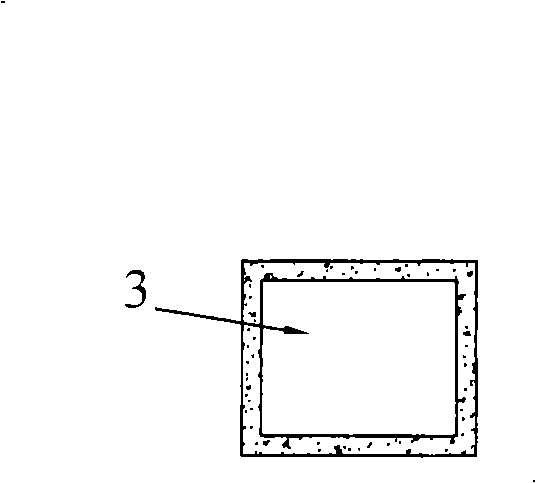

[0028] In this example, the maximum dam height of the hydropower station is 171m, the drop of vertical shaft 1 is 135m, and the flow rate of the flood discharge tunnel is 308.63m 3 / s, the diameter D of shaft 1 is 7m, and the cross section of spillway tunnel 5 is as follows Figure 4 As shown, its width is 5m, and the height of the straight wall is H 3 It is 7m.

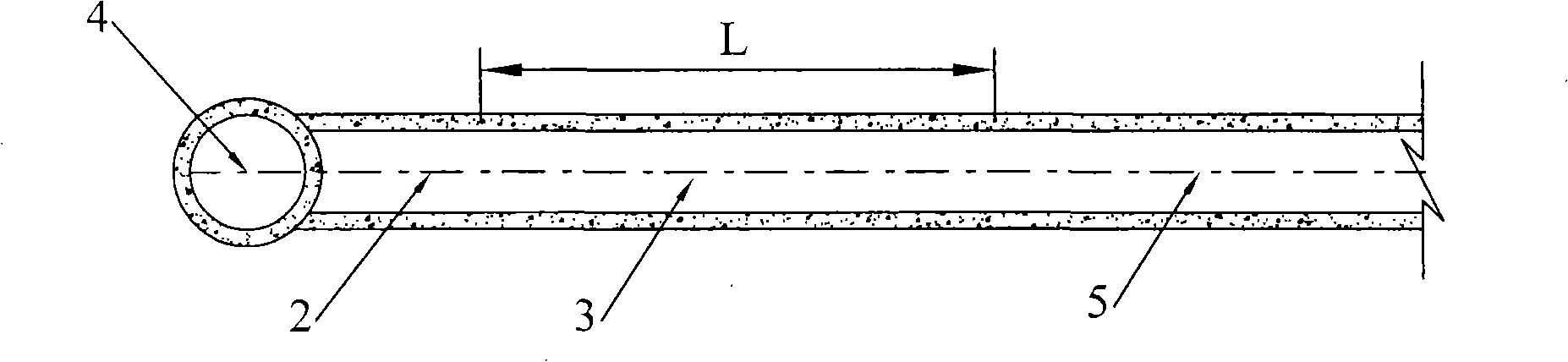

[0029] The structure of rectification energy dissipator at the bottom of the shaft is as follows: figure 1 , figure 2 As shown, it is composed of stilling well 4, anti-arc slope pressure section 2 and straight slope pressure section 3, and each part is made of concrete. The stilling shaft 4 is coaxial with the vertical shaft 1 and is located under the bottom of the flood discharge tunnel. The diameter of the stilling shaft is the same as that of the vertical shaft, which is 7m. The depth of the stilling shaft is H 1 is 10m. The anti-arc slope pressure section 2 and the straight slope pressure section 3 are an i...

Embodiment 2

[0032] In this embodiment, the maximum dam height of the hydropower station is 171m, the drop of shaft 1 is 135m, and the discharge volume is 308.63m 3 / s, the diameter D of the shaft 1 is 7m, the cross section of the flood discharge tunnel 5 is shown in Figure 9, its width is 5m, and the height of the straight wall is H 3 It is 7m.

[0033] The structure of the rectification and energy dissipation work at the bottom of the shaft is shown in Figure 6, Figure 7, and Figure 8, which is composed of a stilling shaft 4, an anti-arc slope pressure section 2 and a straight slope pressure section 3. The difference from Example 1 is: 1. The reverse-arc slope section 2 and the straight slope section 3 are manufactured separately. During installation, the inlet of the reverse-arc slope section 2 is connected to the shaft 1, and the outlet is connected to the straight-line slope section. The inlet end of 3 and the outlet end of the straight slope section 3 are connected to the flood disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com