Forced-feeding method for improving developing quality of goose liver, used feed and forced-feeding machine

A goose fatty liver and quality technology, applied in animal feed, animal feed, application, etc., can solve the problems affecting the quality and output of goose fatty liver, unfavorable absorption and digestion of goose, long period of filling feeding, etc., to achieve the effect of filling feeding Good, simple structure, short feeding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

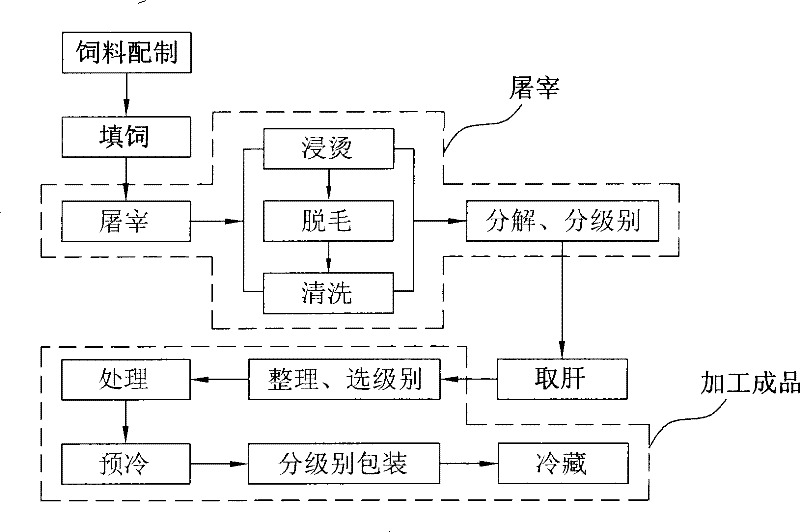

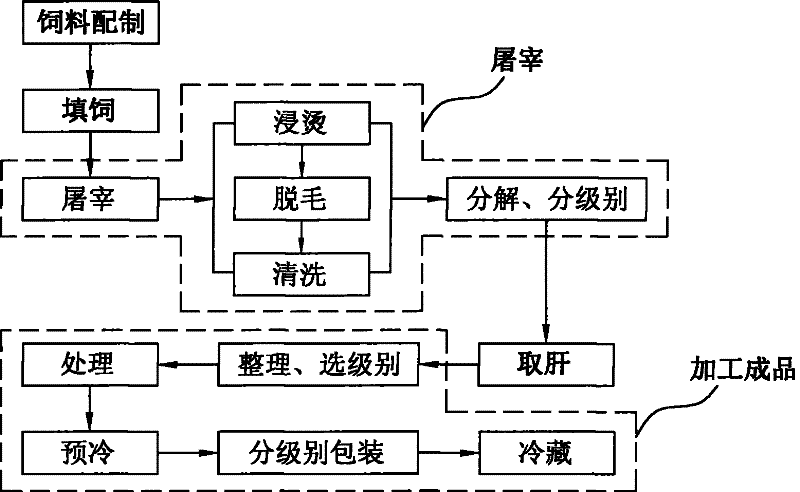

[0017] A filling feeding method to improve the growth quality of goose fat liver. After the geese are fed for 60 days, fattening is carried out. The fattening process is to put the goose in the goose cage, put enough feed to allow the goose to eat freely for 5 to 7 days, and then carry out the fattening process. Feeding, feeding four times a day in the first 7 days of feeding, five times a day in the middle period of 8 days to 12 days, and feeding six times a day in the later period from 13 days to 18-20 days, the total amount of feeding is 1000-1500 grams per day / only. The feed that the above-mentioned feeding method adopts is made of yellow corn as the base material, and the addition of mass ratio is 2.5% goose fat, 1.2% salt, 0.01%~0.02% electrolytic multidimensional and 5% fermented protein feed, goose fat It can play a lubricating role, the electrolytic multi-dimensional is beneficial to the absorption and digestion of geese, and the fermented protein feed can ensure the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com