Method and device for the sulfonation or sulfation of sulfonatable or sulfatable organic substances and for performing faster, strongly exothermic gas/liquid reactions

A sulfation, organic liquid technology, applied in the direction of organic chemistry methods, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as yield loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

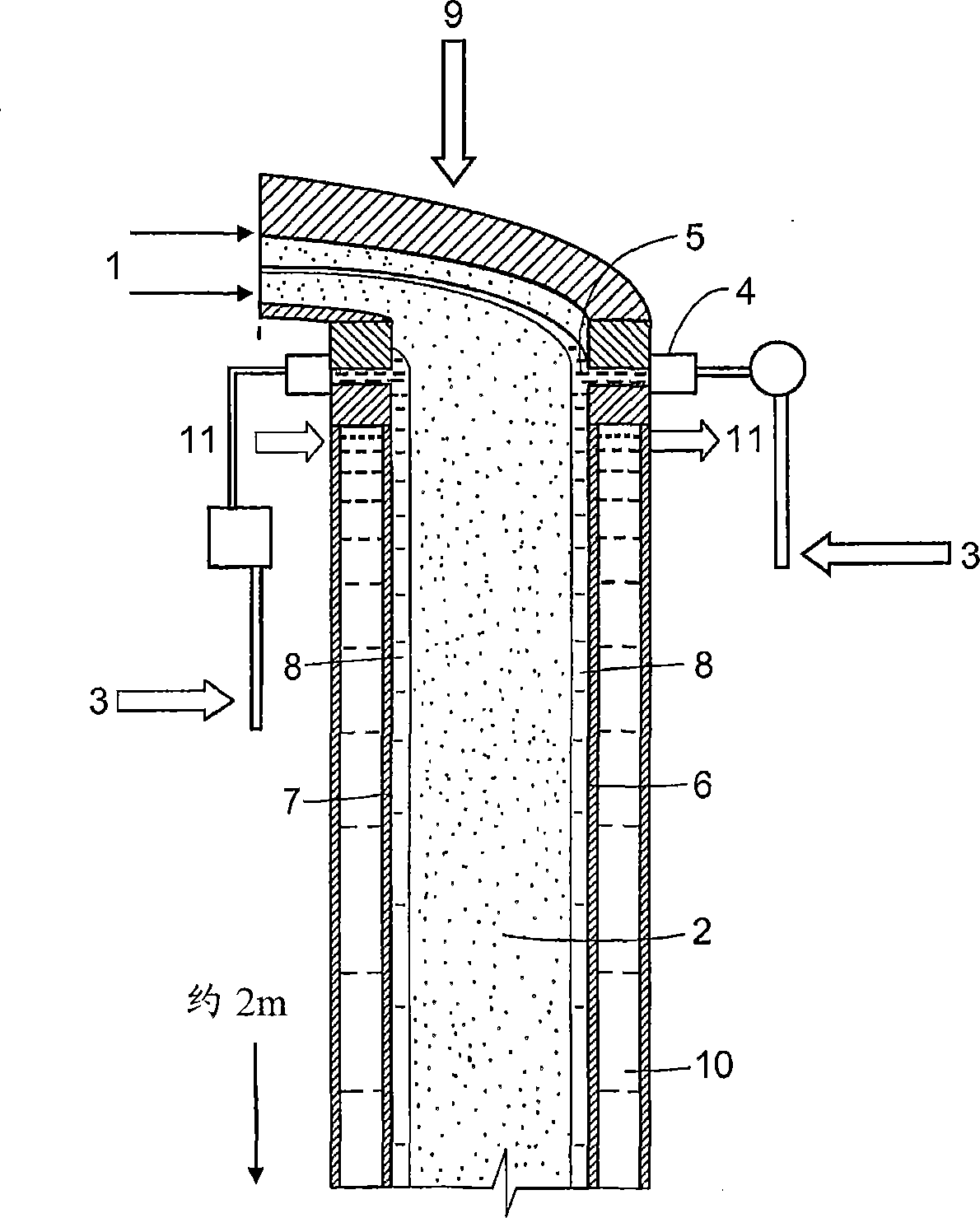

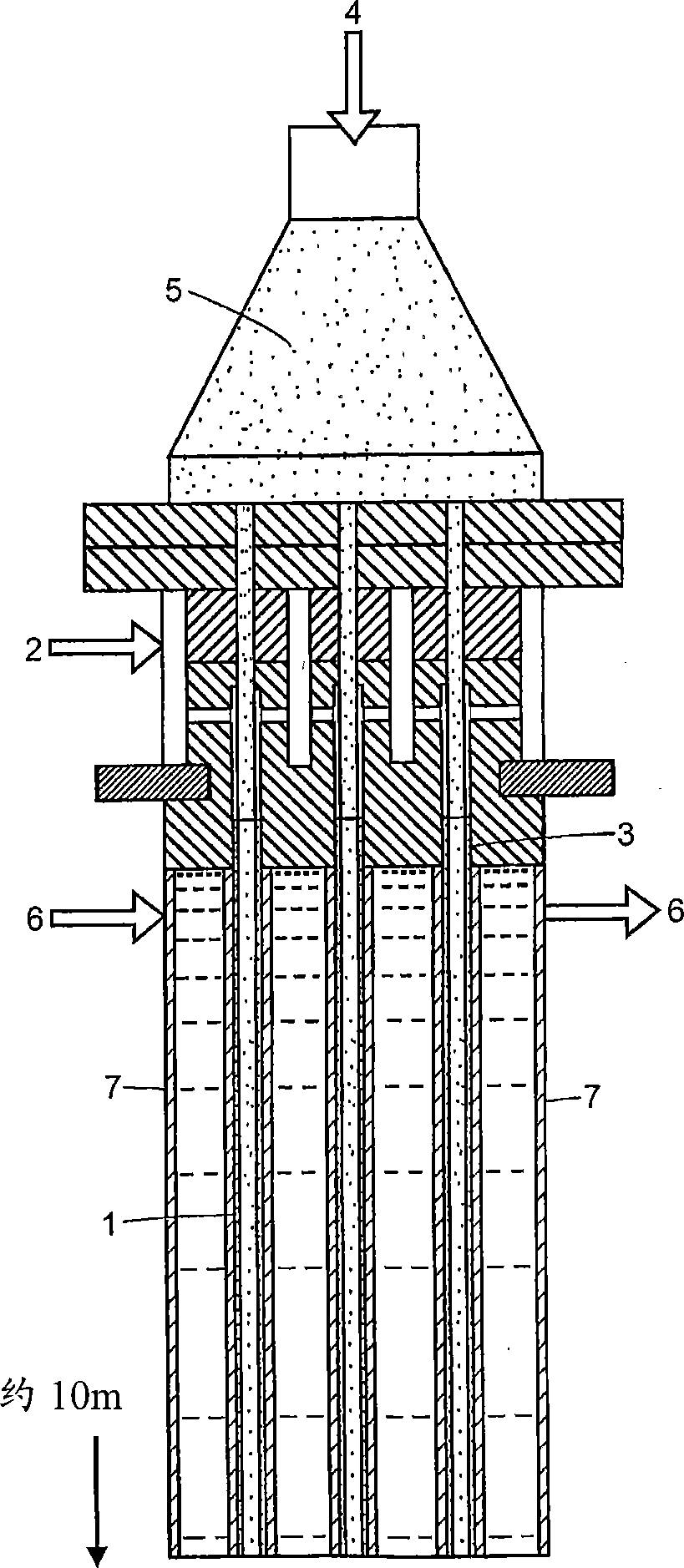

[0053] Example 1 - Preparation of lauryl ether (2EO) sulfate, sodium salt, in an annular gap falling film reactor according to the invention

[0054] in accordance with Figure 5 In the implementation of the annular gap falling film reactor, the outer diameter 124.1mm, inner diameter 116.9mm, thin-walled (about 0.5mm) double-layer pipe with a gap of 2.6mm is installed in the center of the annular gap (annular space) (2) (3). The entire tube distance (wall thickness plus gap) is 3.6mm and the length is 330mm. The diameter of reactor (inner diameter of outer tube (1)) is 5 inches (127mm), and reactor length is 1650mm, and annular gap (2) width is 6.5mm, and in outer tube (1) inner wall (6) and inner tube (1) ) have raw material (4) distributor slits (5) on the outer wall (7) respectively, and each have a cooling jacket (14) (see Figure 5 ). Form the desired size of the inner pipe diameter of the double-layer pipe (3), so that SO 3 50% of the gas is introduced through the ann...

Embodiment 2

[0067] Example 2 - Preparation of lauryl ether (3EO) sulfate, sodium salt, liquid in an annular gap falling film reactor according to the invention

[0068] In the embodiment of the annular gap falling film reactor, a thin-walled double-layer tube is installed in the annular gap, the tube distance (gap) is 3.6 mm, and the length is 330 mm. The reactor has a diameter of 5 inches (127 mm), a length of 1650 mm, and a 6.5 mm wide annular gap, a feed distributor slit on the inner wall of the outer tube and an outer wall of the inner tube, and each has a cooling jacket (see Figure 5 ).

[0069] Through the two distributor slits, in the amount of 297 kg / h (mass flow meter) (=0.906 kmol / h of fatty alcohol ethoxylate), at 40 ° C on the surface of the two annular gaps with 3 moles C12 / 14 fatty alcohol ethoxylate of ethylene oxide (fatty alcohol = ALFOL C12 / C14, C12 content 51-57%, C14 content 41-47%, molecular weight 196) (molecular weight 328, APHA color = 10) . Form the required di...

Embodiment 3

[0081] Example 3 - Preparation of α-olefin sulfonate, sodium salt in a middle ring gap falling film reactor according to the invention

[0082] In the embodiment of the annular gap falling film reactor, a thin-walled double-layer tube is installed in the annular gap, and its tube distance (gap) is 6.5 mm and its length is 120 mm. The reactor has a diameter of 5 inches (127 mm), a length of 2 m, an annular gap width of 10 mm, a feed distributor slit on the inner wall of the outer tube and an outer wall of the inner tube, and each has a cooling jacket (see Figure 5 ).

[0083] C12 / 16 α-olefins ( C12 up to 2%, C14=62-70%, C16 content 29-37%, molecular weight 214, APHA=30). Form the desired size of the inner tube diameter of the double-layer tube so that the SO 3 50% of the gas is introduced through the annular gap and 50% is introduced through the double pipe. The feed temperature of the cooling water in the two cooling jackets was adjusted to 15°C. SO produced by burning su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com