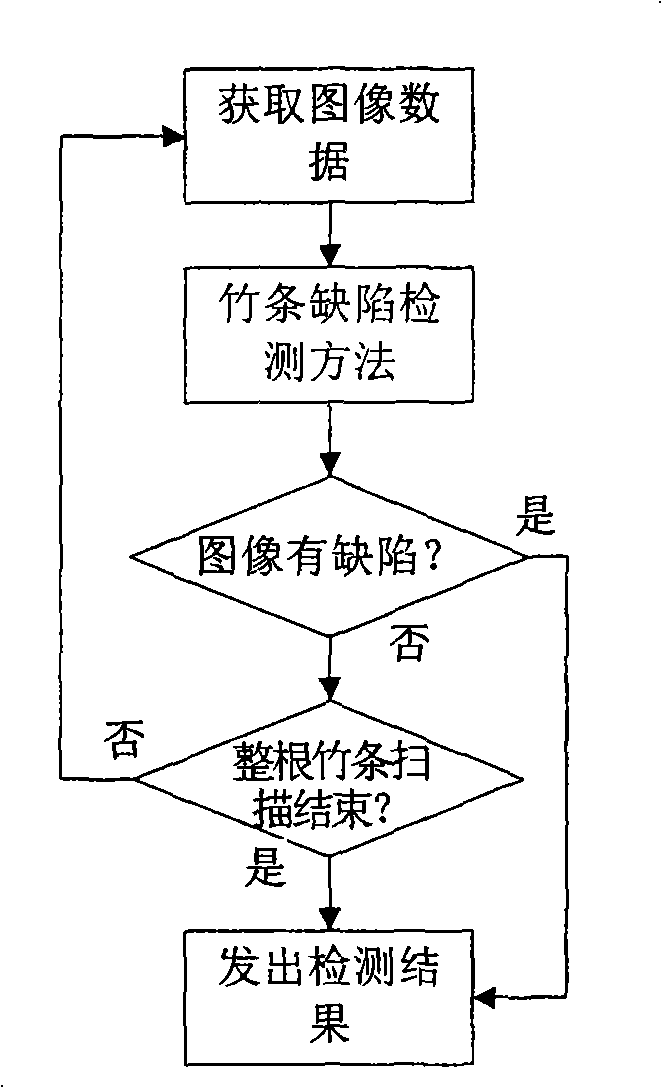

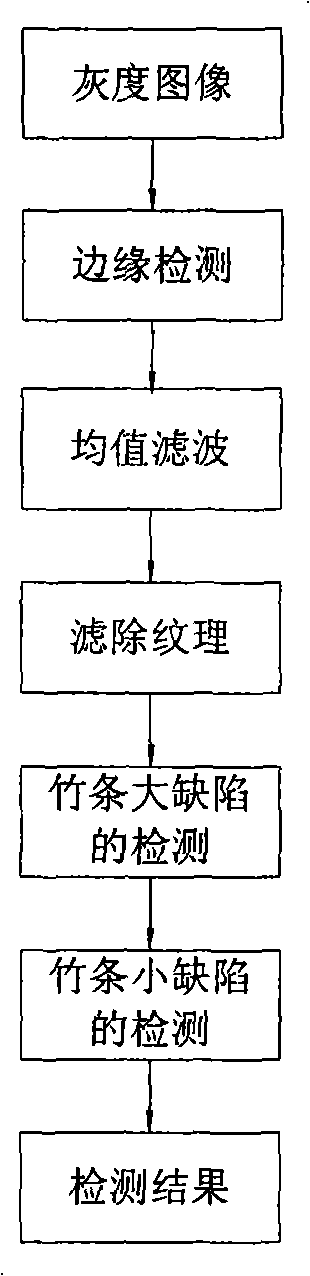

Bamboo strip defect on-line detection method based on machine vision

A technology of machine vision and detection method, which is applied in the field of visual detection, can solve problems such as the inability to automatically detect bamboo strips, and achieve the effect of solving misjudgment and missed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

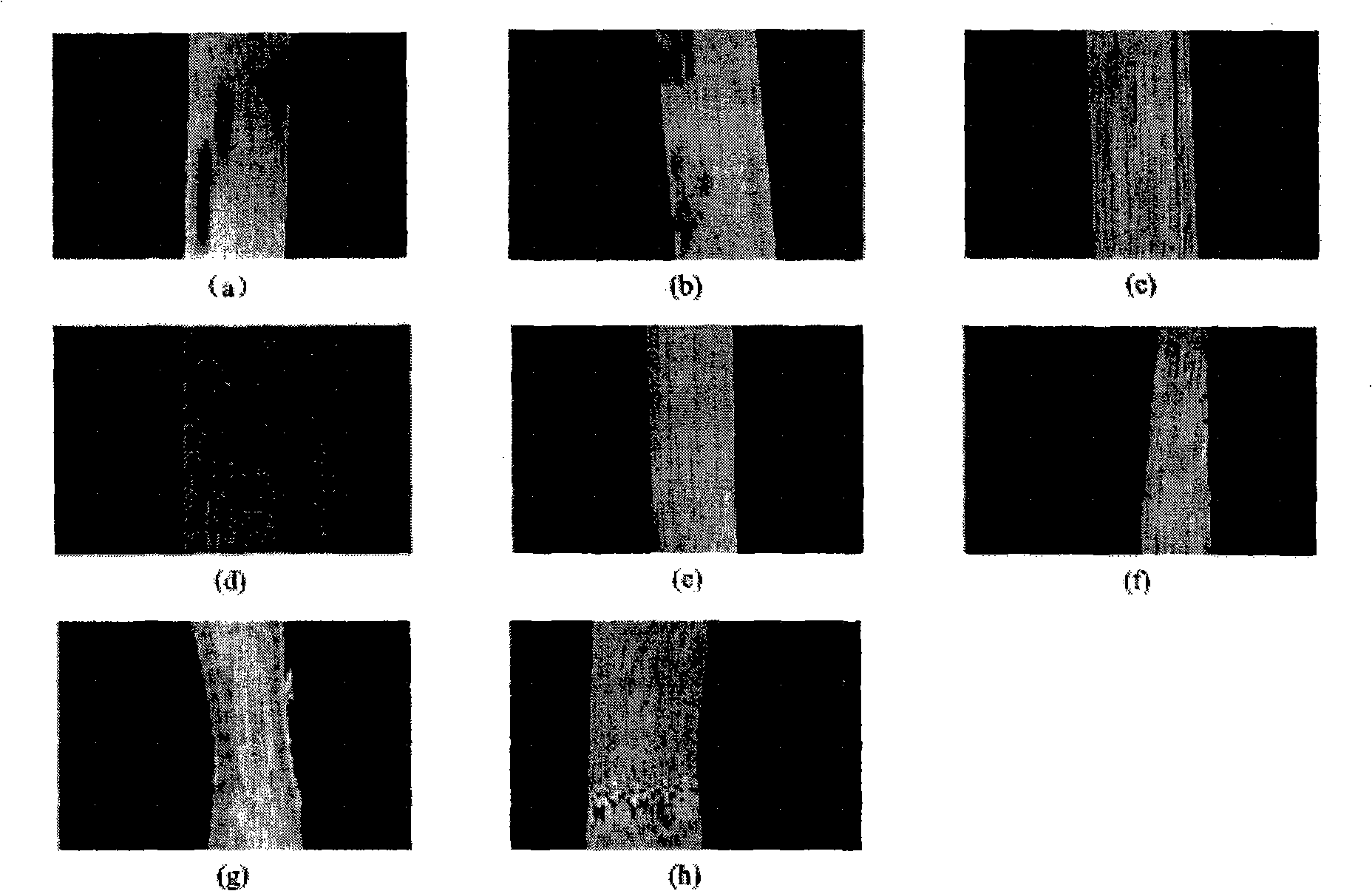

Embodiment Construction

[0036] The width of the bamboo strips detected by the present invention is 14mm-25mm, the thickness is 6mm-10mm, and the length is 0.9m-2.6m. The bamboo strips are narrow and long workpieces. The light source is used to irradiate the four surfaces of the bamboo strips along the length direction vertically. In the acquired bamboo strip images, the triangular strip defect is manifested as the two border lines of the bamboo strips have a large angle; Compared with the normal area on the surface of the bamboo strip, the green area of the bamboo has a darker brightness, a smaller gray value, and a larger area; the parallelogram defect area and the oblique cut defect area appear in the image as the shadow area on the side of the bamboo strip. Compared with the normal area on the surface of bamboo strips, the brightness is darker, the gray value is smaller, and the area is larger; for smaller moth-eaten holes, cracks and cracks, it is a slender feature with a smaller defect area, but t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com