Macrotype four-way reversing valve

A four-way reversing valve, large-scale technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problems of large space occupation, easy failure, inconvenient maintenance, etc., to achieve simple flow path and simple circuit control. , the effect of taking up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

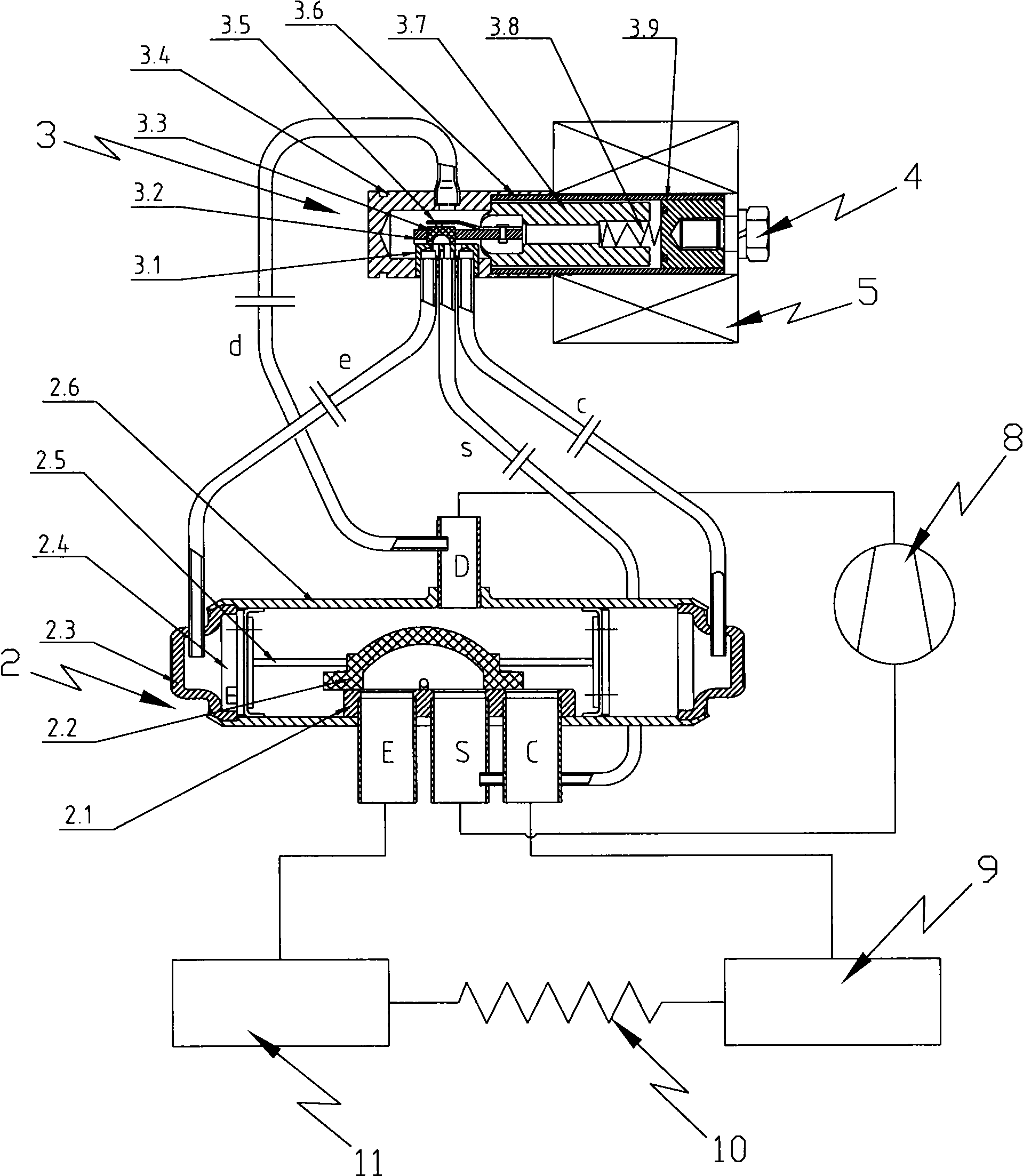

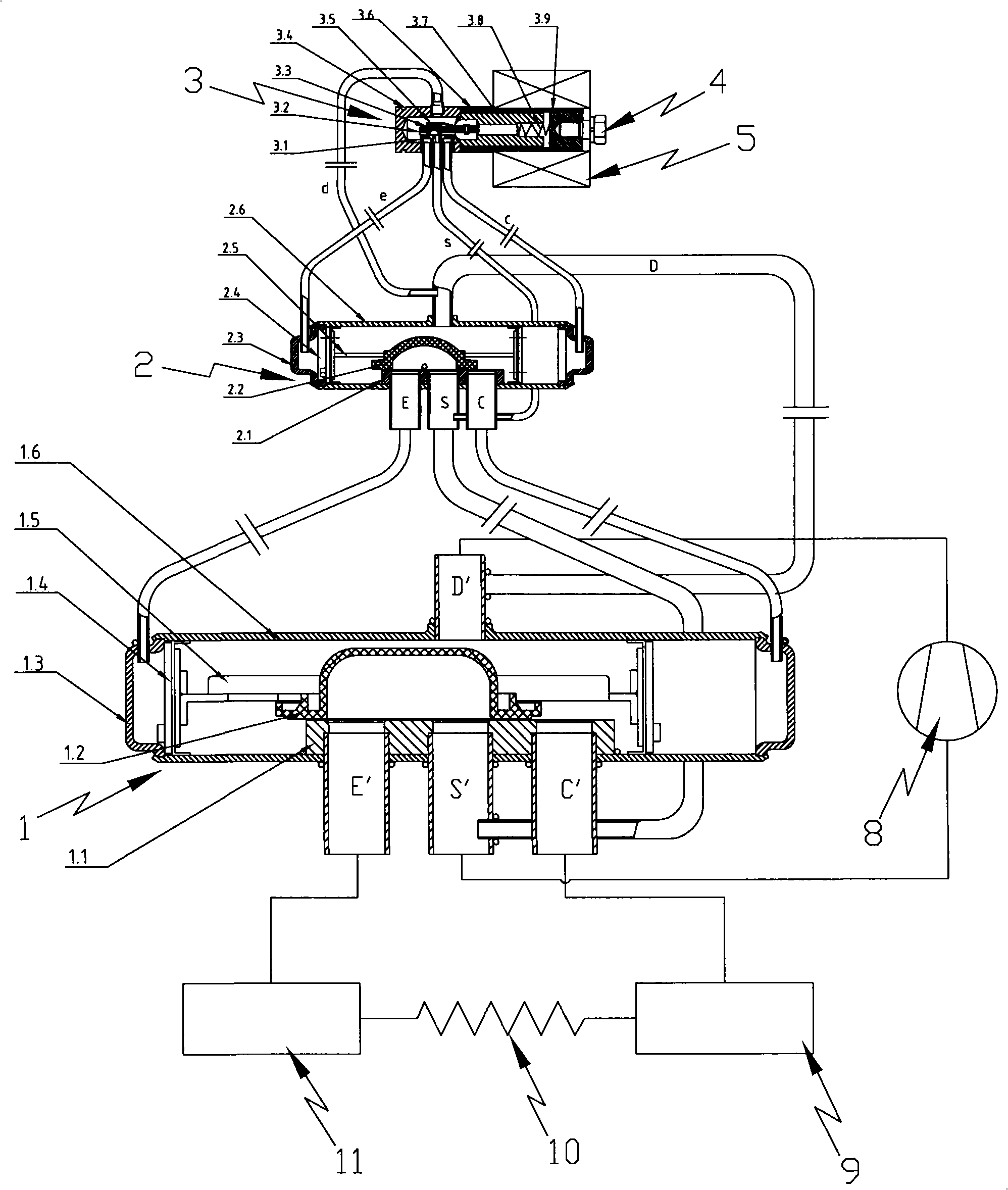

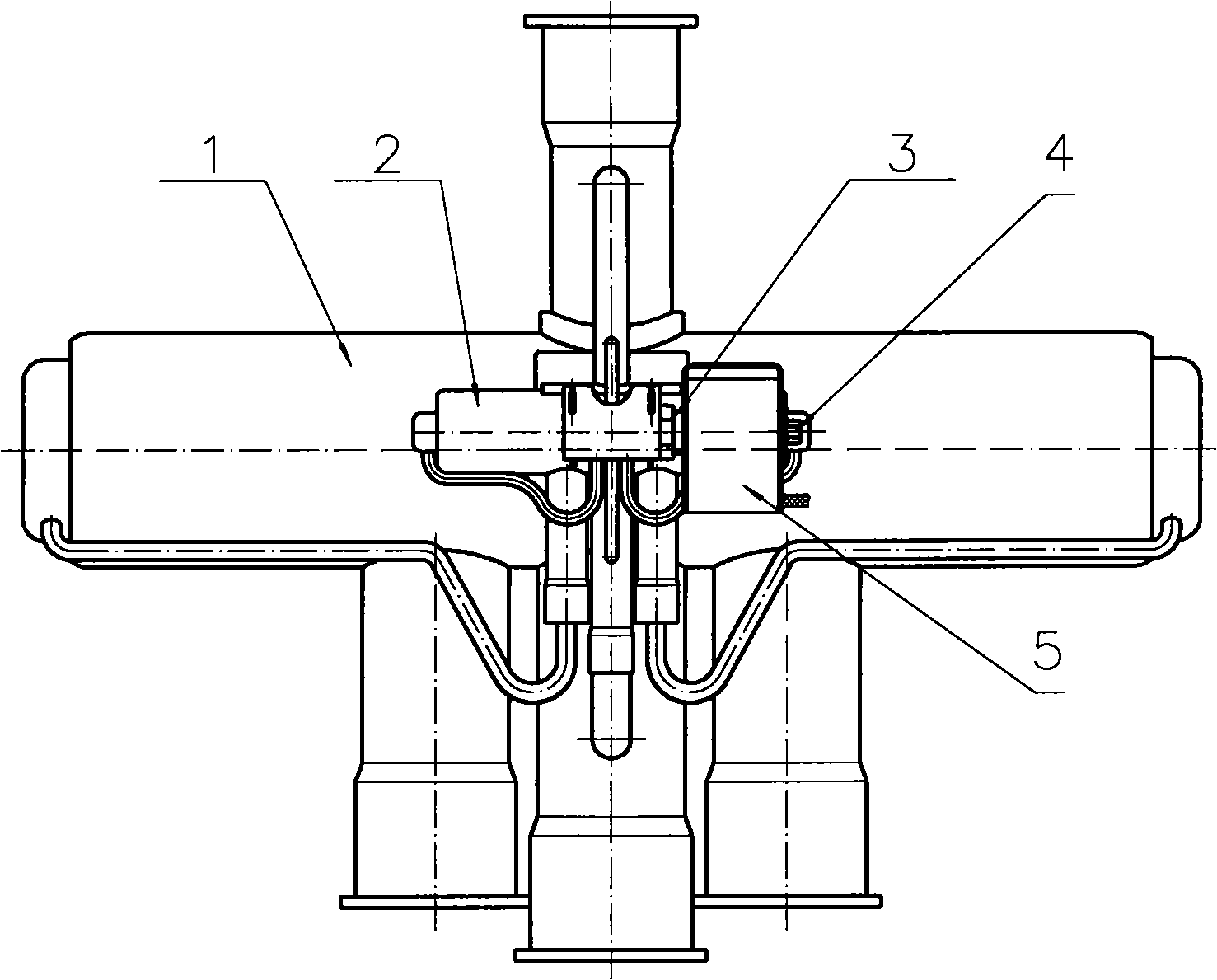

[0036] Such as Figure 3A ,3B As shown, the four-way reversing valve of the present invention mainly consists of four parts: a large main valve 1, a control main valve 2, a pilot valve 3, and a coil 5. The large main valve 1 and the control main valve 2 are connected through a control pipe; the control main valve 2 and the pilot valve 3 are connected through a capillary tube; the pilot valve 3 and the coil 5 are connected and fixed by fixing screws 4; the large main valve 1 is welded with a fixed Plate 12, connecting plate 13 is welded on the control main valve 2, fixed plate 12 and connecting plate 13 are fixed by connecting screw 14. Thus, the purpose of the present invention to use the original main valve, the pilot valve and the electromagnetic coil as the control valve to control the refrigerant flow direction of the large main valve is realized. A mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com