Inflation mould for filling

A technology of inflatable tires and inflatable nozzles is applied in the fields of formwork/template/work frame, building components, and on-site preparation of building components, which can solve problems such as large volume efficiency, complex production molds, and large transportation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

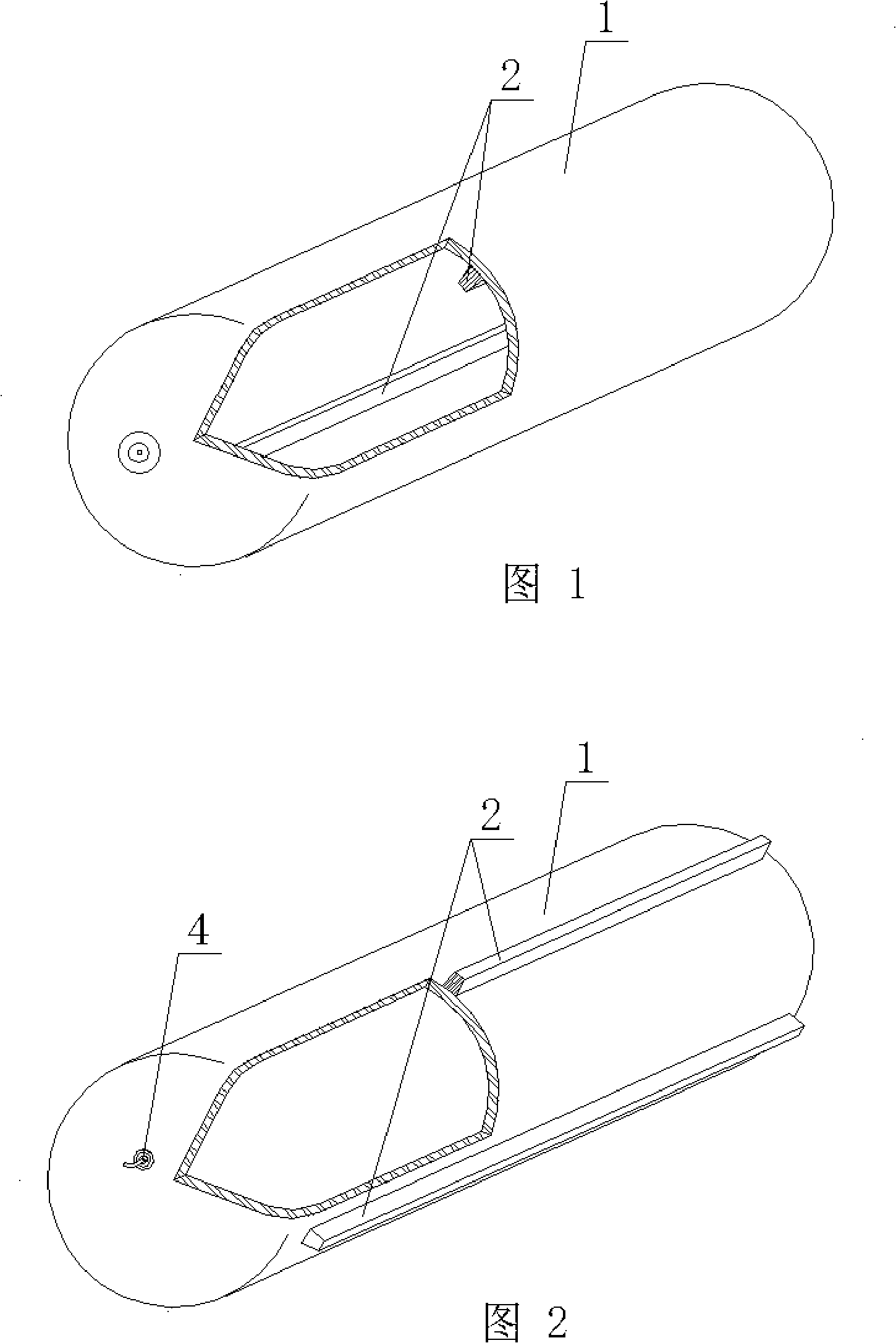

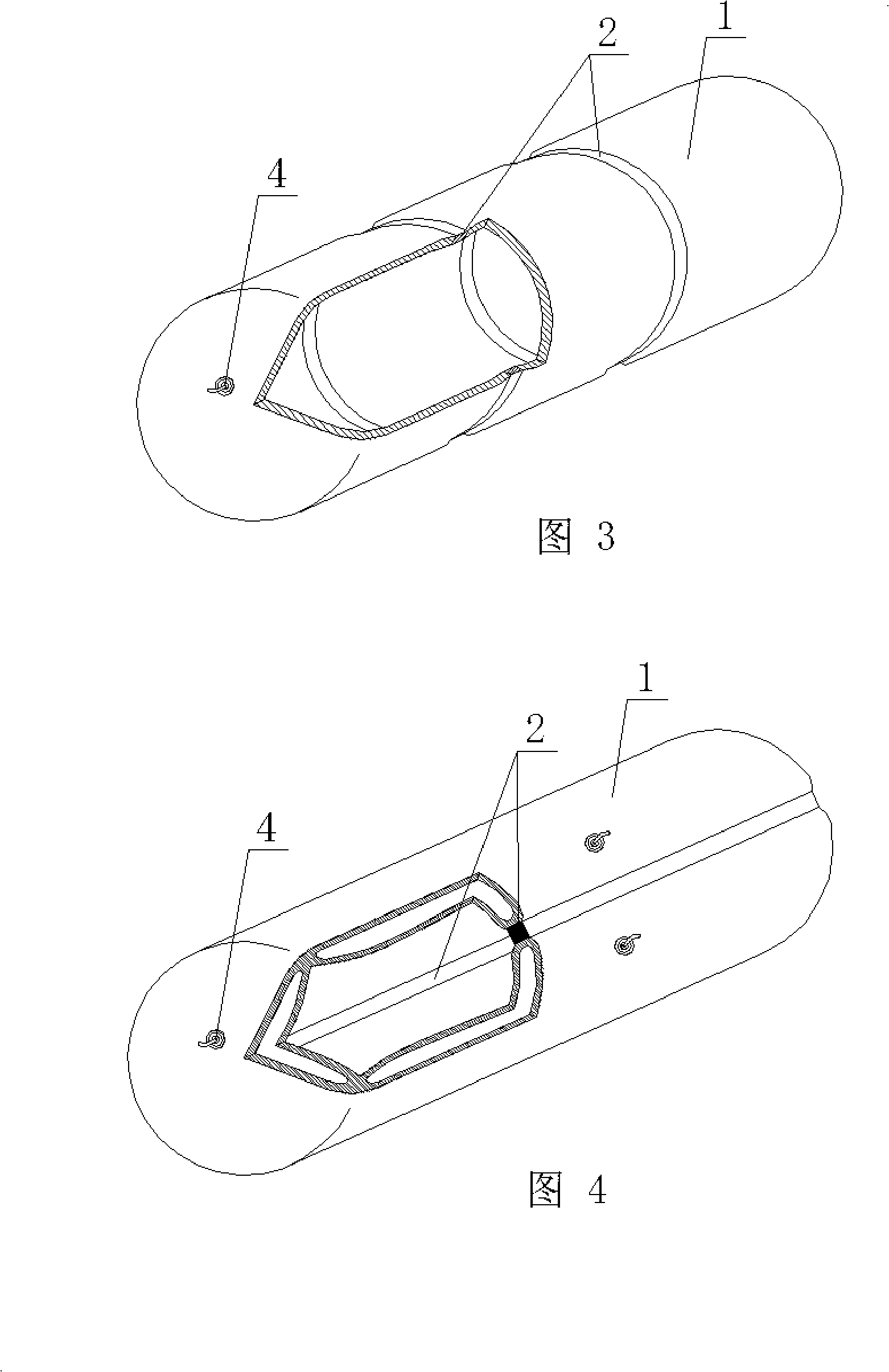

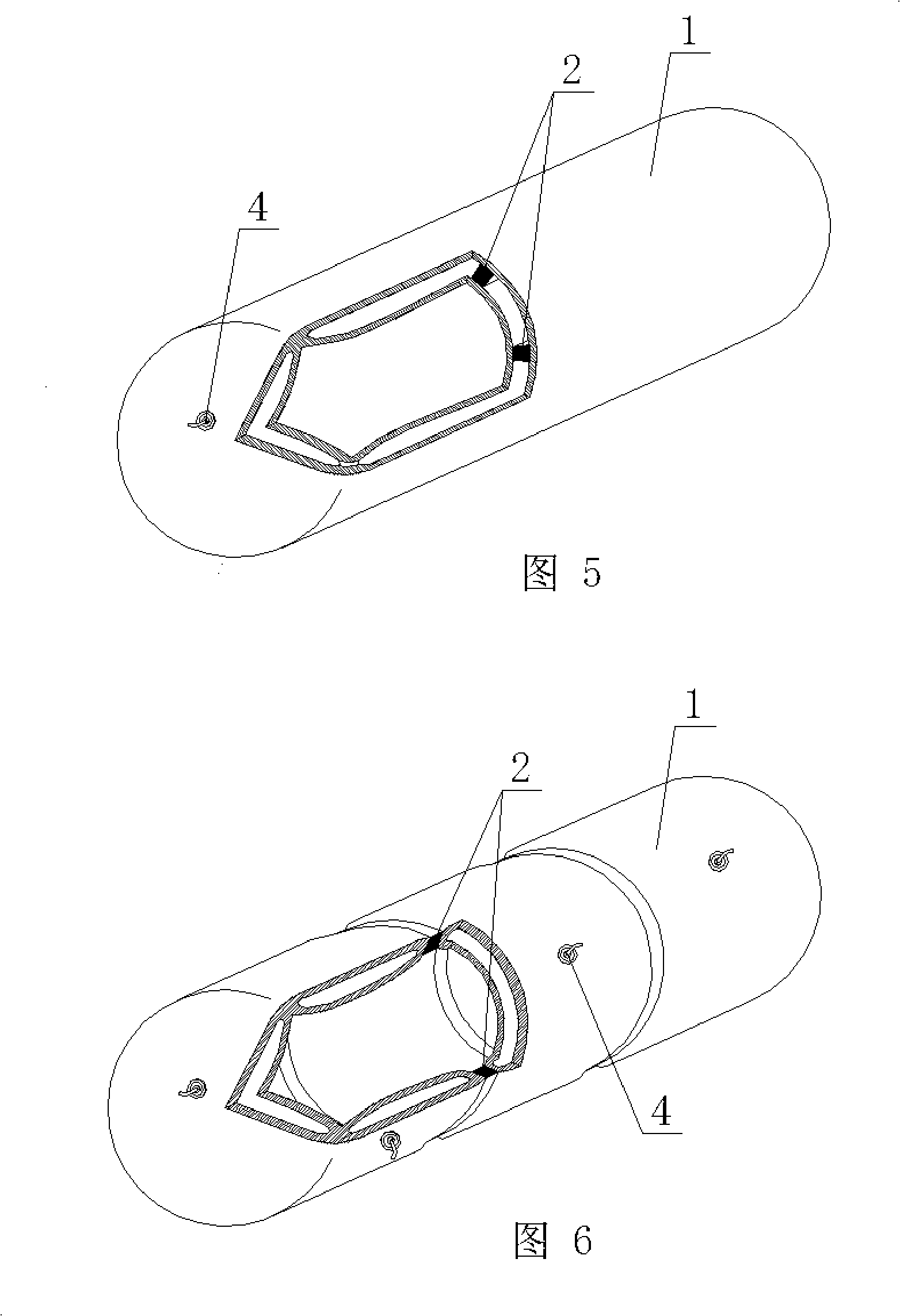

[0026] As shown in the drawings, the present invention includes an inflatable airbag membrane 1 and a skeleton 2, and is characterized in that the inflatable airbag membrane 1 is a tubular member, and the skeleton 2 is arranged on the membrane wall of the inflatable airbag membrane 1. Fig. 1 is a schematic structural diagram of Embodiment 1 of the present invention. In each accompanying drawing, 1 is an inflatable airbag membrane, and 2 is a skeleton. In each accompanying drawing, those with the same number have the same description. As shown in FIG. 1 , the inflatable airbag membrane 1 and the skeleton 2 are characterized in that the inflatable airbag membrane 1 is a tubular member, and the skeleton 2 is arranged on the membrane wall of the inflatable airbag membrane 1 .

[0027] The present invention is also characterized in that the skeleton 2 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com