High-efficiency low-temperature catalysis gasification method for coal

A high-efficiency, low-temperature technology, used in the manufacture of combustible gas, the petroleum industry, and the combination of fuel pre-dry distillation, etc., can solve the problem of not being promoted for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Experiment 1:

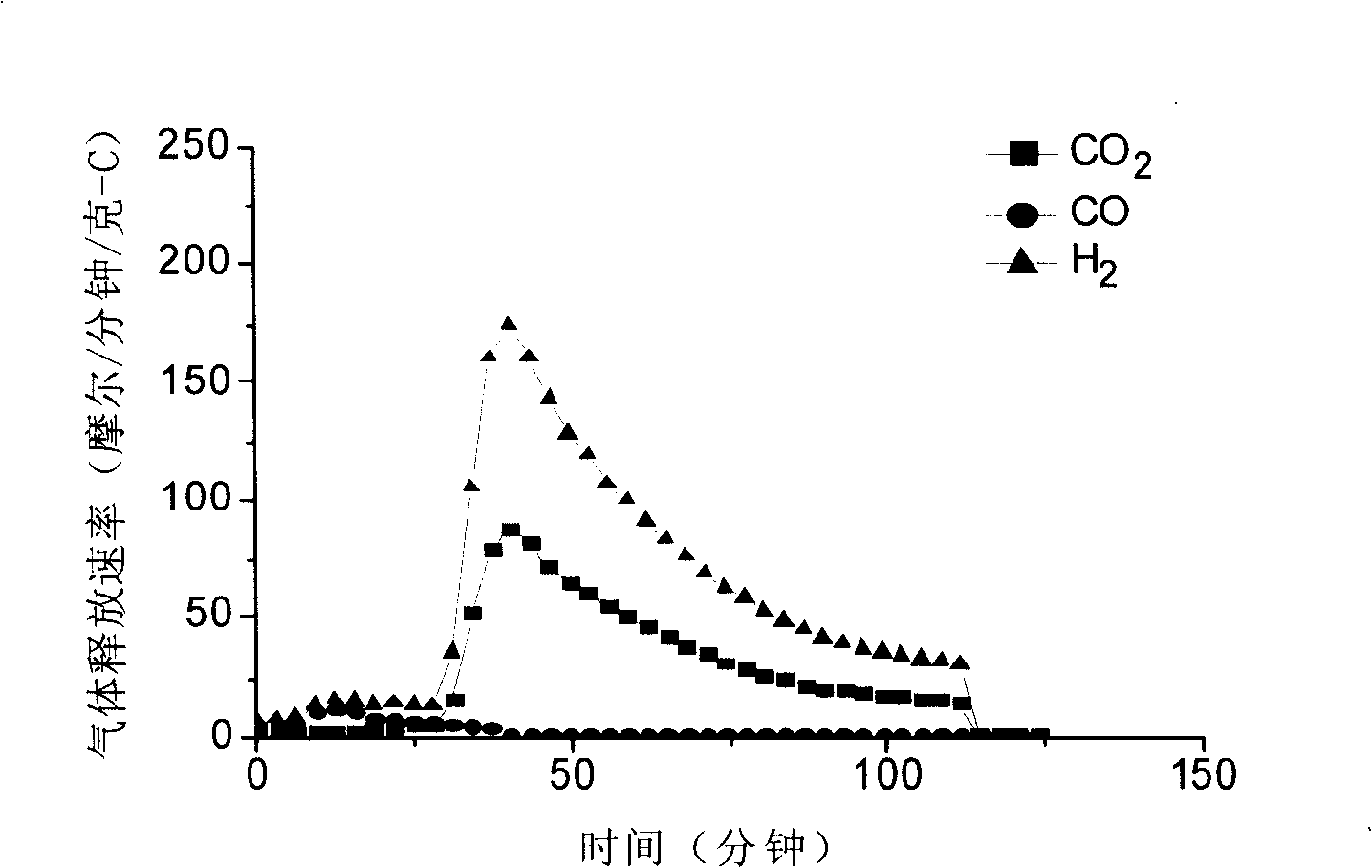

[0040] Coal sample A is heated and pyrolyzed in a fixed-bed reactor at 900°C, and the yield of coal char is 80% (dry basis), and the release rate of the generated gas is generated when the coal char is vaporized in a fixed-bed reactor at 750°C Such as figure 1 shown.

[0041] Experiment 2:

[0042] Add 10% potassium carbonate to the coal coke obtained from the same coal sample, mix well, and carry out steam gasification at 750°C, the release rate of the generated gas is as follows figure 2 shown.

[0043] Experiment 3:

[0044] Add 10% calcium hydroxide to coal sample A, pyrolyze it at 900°C, mix the obtained char with 10% potassium carbonate, and gasify it at 750°C, the release rate of the generated gas is as follows: image 3 shown.

[0045] In the above three gasification experiments, except for the presence or absence of additives, the other pyrolysis and gasification conditions are the same, and the release rate of the generated gas reflects ...

Embodiment 2

[0048] Experiment 4:

[0049] Coal sample B is heated and pyrolyzed in a fixed-bed reactor at 700°C, and the yield of coal char is 88% (dry basis), and the release rate of the gas produced by steam gasification of coal char in a fixed-bed reactor at 750°C Such as Figure 4 shown.

[0050] Experiment 5:

[0051] Coal char obtained from the same coal sample is added with 10% potassium carbonate, mixed evenly, and steam gasified at 750°C, the release rate of the generated gas is as follows: Figure 5 shown.

[0052] Experiment 6:

[0053] Coal sample A is added with 10% calcium hydroxide and pyrolyzed at 700°C. The obtained coal char is then mixed with 10% potassium carbonate and gasified at 750°C. The release rate of the generated gas is as follows: Figure 6 shown.

[0054] In the above three experiments, except for the presence or absence of additives, the other pyrolysis and catalytic conditions are the same, which reflects the influence of the presence or absence of ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com