Method for preparing perchlorinated cyclopentadienyl

A technology for substituting cyclopentadiene and monocyclopentadiene, which is applied in the field of synthesis of organic compounds, can solve the problems of low content and low yield of perchlorinated cyclopentadiene products, and improve the utilization rate and cost of chlorine gas. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

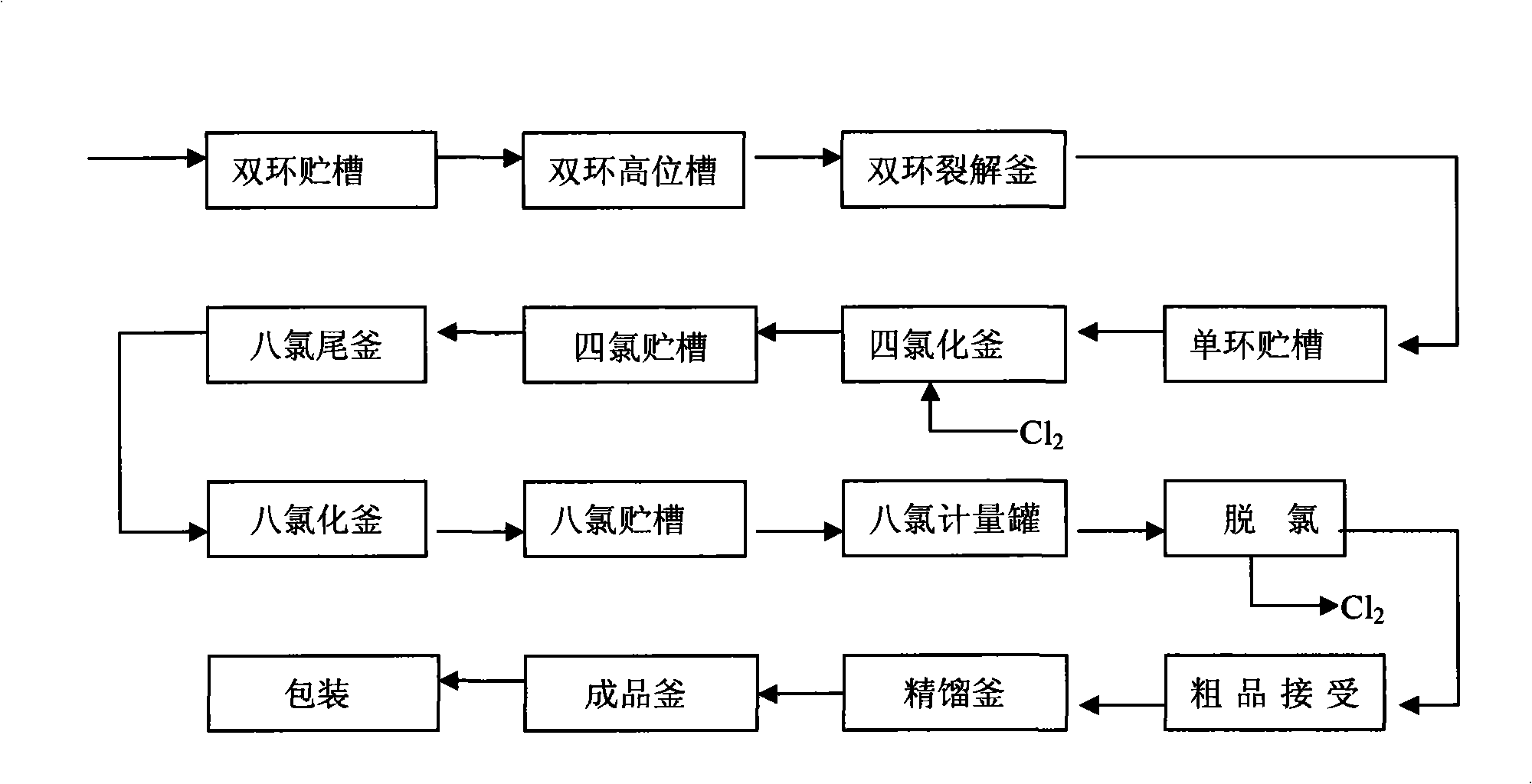

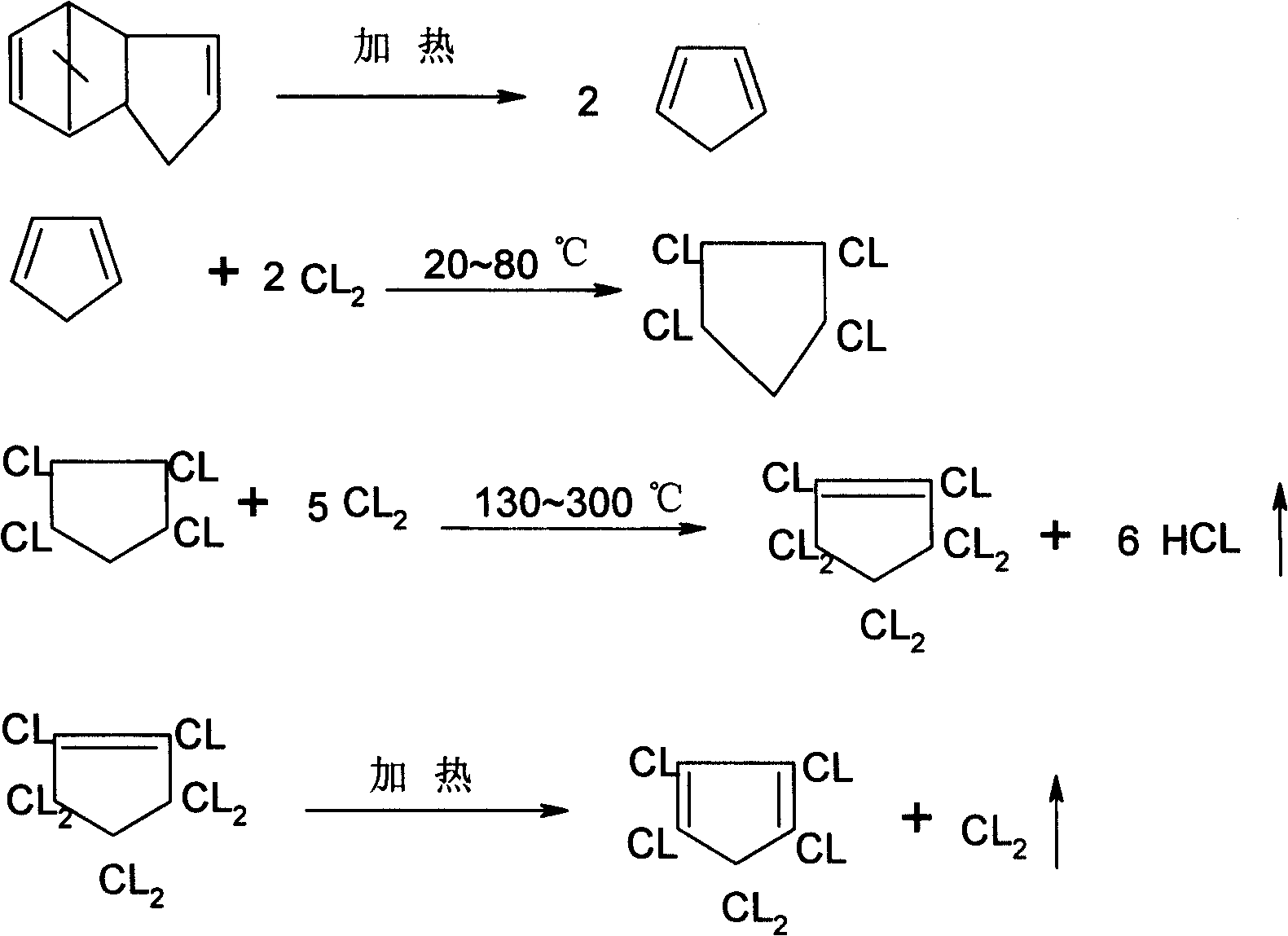

Method used

Image

Examples

example 1

[0029] In a 500L cracking kettle, first add 100Kg of dicyclopentadiene, and slowly raise the temperature of the cracking kettle to 300-350°C through an electric heating package. The diene is added to the cracking tank, and the steam flows into the storage tank after quenching to form monocyclopentadiene. While adding monocyclopentadiene to a 500L tetrachlorination kettle, feed chlorine gas, keep the temperature of the tetrachlorination kettle at 20-40°C, and transfer the unreacted chlorine gas in the tetrachlorination kettle back into the tetrachlorination kettle to participate in the chlorination reaction , when the reflux liquid is slightly yellow through the exhaust gas reflux sight glass, it means that the tetrachloride has reached the end point. 1,2,3,4-tetrachlorocyclopentane is transferred in the octachlorination still, and the octachlorination still has four stages in series, and successively the 1st, 2nd, 3rd, 4th grade octachlorination stills Add 350Kg of 1,2,3,4-te...

example 2

[0031] In a 500L cracking kettle, first add 100Kg of dicyclopentadiene, and slowly raise the temperature of the cracking kettle to 450-500°C through an electric heating package. Diene is added to the cracking tank, and the steam is rapidly cooled to form monocyclopentadiene. While adding monocyclopentadiene to a 500L tetrachlorination kettle, chlorine gas is introduced to keep the temperature of the tetrachlorination kettle at 30-50°C. The unreacted chlorine in the kettle is transferred back into the tetrachlorination kettle to participate in the chlorination reaction. When the reflux liquid is slightly yellow through the tail gas reflux sight glass, it means that the tetrachlorination has reached the end. 1,2,3,4-tetrachlorocyclopentane is transferred in the octachlorination kettle, the octachlorination kettle has three stages in series, successively add 350Kg 1 , 2,3,4-Tetrachlorocyclopentane, keep the temperature at 280-300°C, 220-250°C, 150-180°C respectively, after 8 hour...

example 3

[0033] Slowly raise the temperature of the tubular cracker through an electric heating pack, and at the same time, feed nitrogen into the tubular cracker. When the temperature reaches 150°C, continuously feed dicyclopentadiene through a flow meter at a rate of 140 kg per hour, and turn off the nitrogen at the same time , The steam from the tubular cracker is quenched into monocyclopentadiene. While adding monocyclopentadiene to the 500L tetrachlorination kettle, feed chlorine gas, keep the temperature of the tetrachlorination kettle at 70-80°C, and transfer the unreacted chlorine gas in the tetrachlorination kettle back into the tetrachlorination kettle to participate in the chlorination reaction , when the reflux liquid is slightly yellow through the exhaust gas reflux sight glass, it means that the tetrachloride has reached the end point. 1,2,3,4-tetrachlorocyclopentane is transferred in the octachlorination still, and the octachlorination still has four stages in series, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com